Construction method of thermal-insulation anti-cracking protective layer of thermal-insulation structure integrated prefabricated external wall panel

A construction method and technology for exterior wall panels, which are applied in thermal insulation, building components, building structures, etc., can solve problems such as unusability, anchoring alkali-resistant fiberglass mesh, and wall seepage and leakage, and achieve cost savings and convenience. Learn to master and reduce the effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

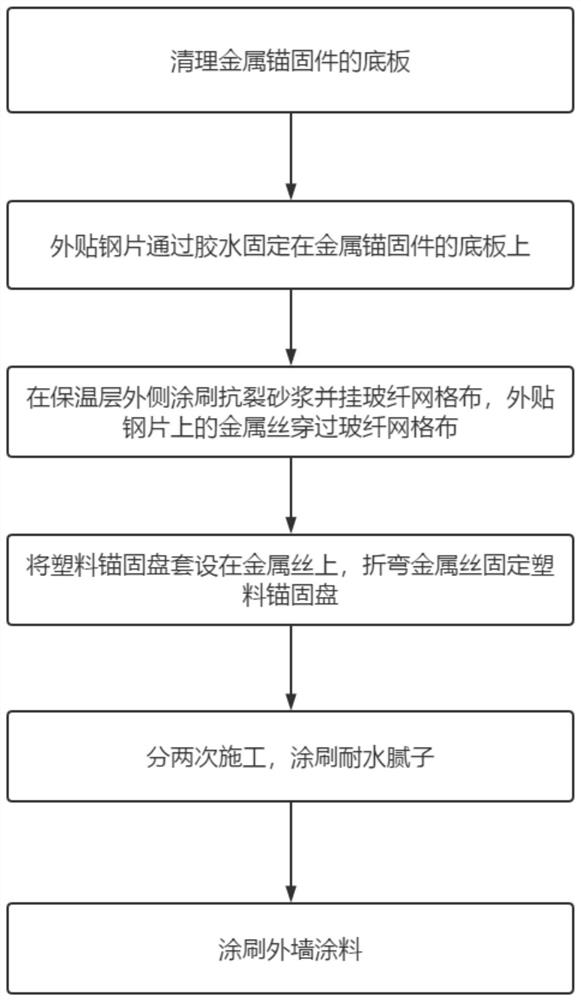

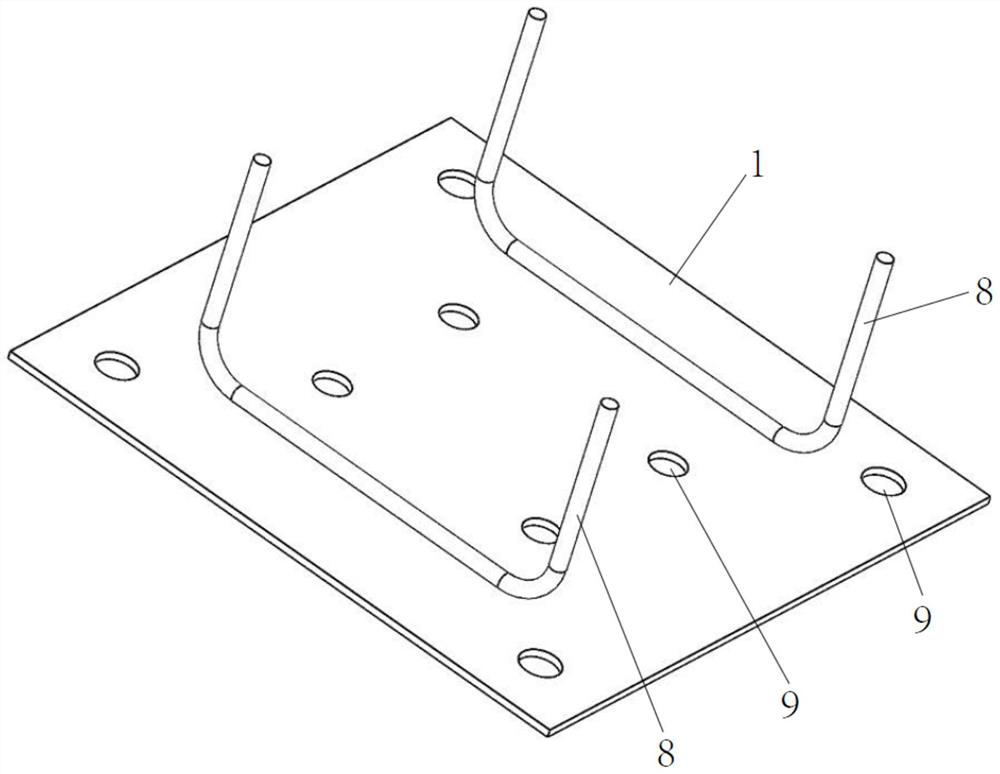

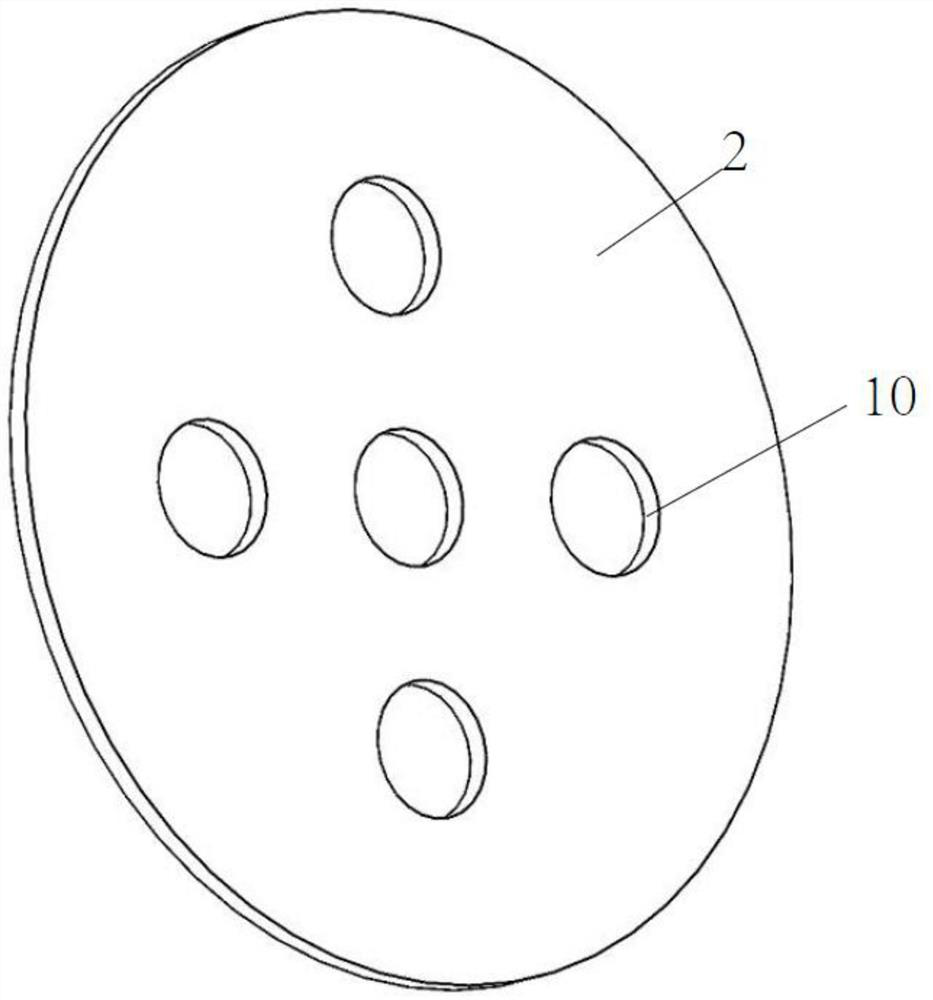

[0035] refer to Figure 1 to Figure 5 As shown, an embodiment of the construction method of the insulation structure integrated prefabricated exterior wall panel of the present invention for the thermal insulation and anti-crack protection layer, the prefabricated exterior wall panel 3 is constructed by using the externally attached steel sheet 1 and the plastic anchor plate 2, and the prefabricated exterior wall panel The wall panels have been installed. The prefabricated exterior wall panels include metal anchors 4, a precast concrete structure layer 5 and an insulation layer 6. The metal anchors fix the insulation layer on the surface of the precast concrete structure layer. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com