Degradable low-water-vapor-transmittance heat-sealable two-way stretching polylactic acid smoke film and preparation method thereof

A technology of biaxial stretching and polylactic acid, which is applied in the field of flexible packaging, can solve problems such as poor water vapor barrier properties, and achieve the effects of degradable heat sealing performance, high heat sealing strength, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Specifically, the present invention also provides a method for preparing the degradable low water vapor transmission rate heat-sealable biaxially oriented polylactic acid cigarette film, the steps of which are as follows:

[0037] (1) Preparation of water vapor barrier coating: Add polyurethane polymer coating, inorganic powder, and suspending agent in sequence in a certain weight ratio in the container, stir evenly, then add water, continue stirring evenly, finally add crosslinking agent, and stir evenly Standing and defoaming to obtain the water vapor barrier coating;

[0038] (2) Weigh crystalline polylactic acid slices, non-crystalline polylactic acid slices, anti-blocking agents and smoothing agents according to a certain weight ratio, and put them into a twin-screw extruder to obtain inner layer 13 through melt blending, extrusion, and granulation masterbatch, spare;

[0039] (3) Weigh crystalline polylactic acid slices, non-crystalline polylactic acid slices, an...

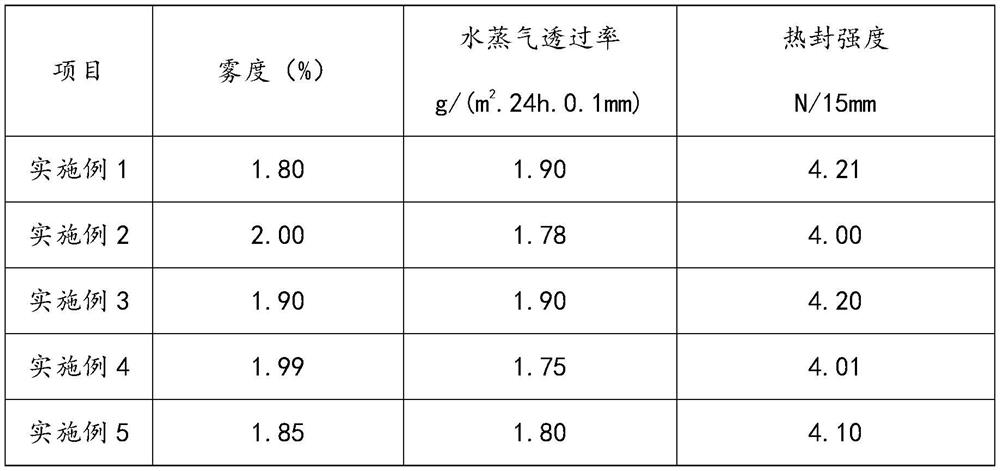

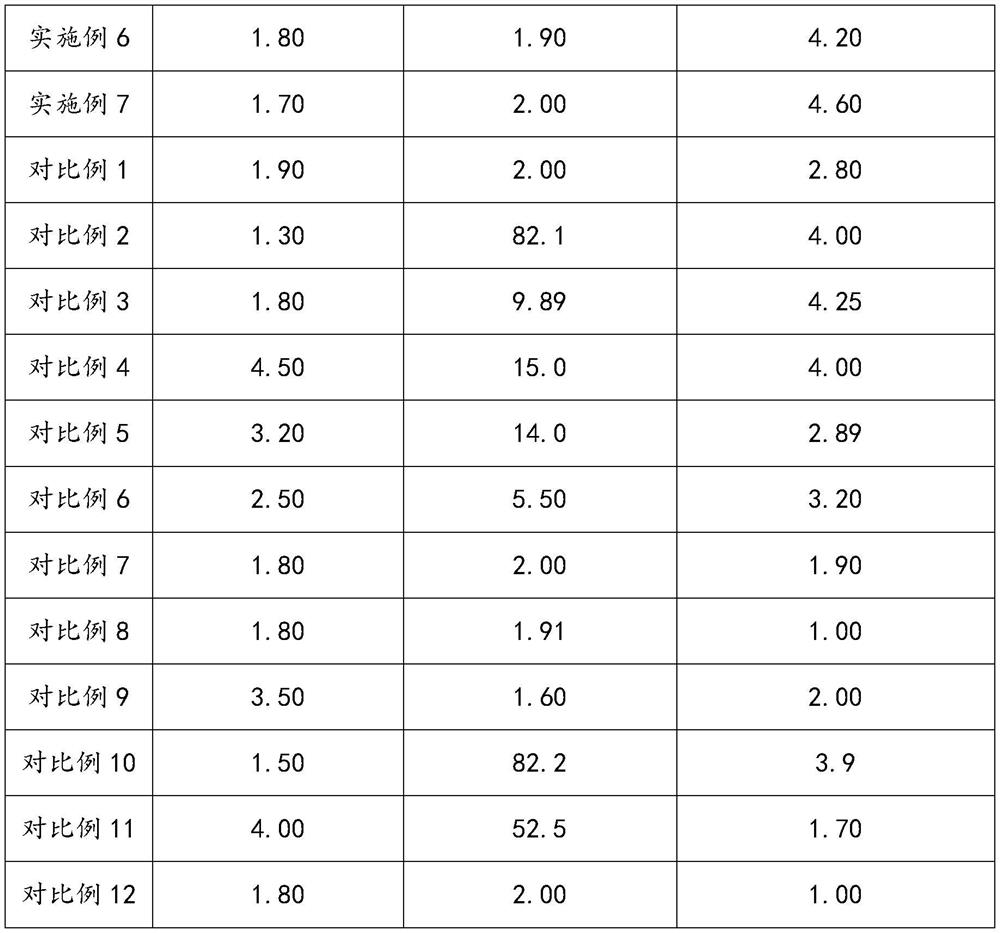

Embodiment 1

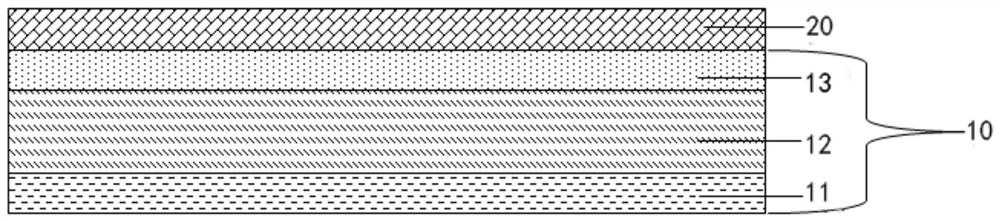

[0046] The film layer structure of the biaxially stretched polylactic acid cigarette film includes a BOPLA film layer 10 and a water vapor barrier layer 20; the BOPLA film layer 10 is followed by a surface layer 11, a core layer 12 and an inner layer 13 from bottom to top, which are obtained through three layers. Layer casting co-extrusion and biaxial stretching are made, and the inner layer 13 in the BOPLA film layer 10 is connected with the water vapor barrier layer 20; wherein, the thickness of the BOPLA film layer 10 is 15um; the water vapor barrier layer 20 The thickness is 0.5um;

[0047] The water vapor barrier layer 20 is composed of polyurethane polymer coating, inorganic powder, suspending agent, crosslinking agent and water in a mass ratio of 85.0:5.89:0.50:1.00:33.7.

[0048] In parts by weight, the raw material components of the inner layer 13 of the BOPLA film layer 10 include 75.0 parts of crystalline polylactic acid slices, 23.0 parts of non-crystalline polylac...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is only:

[0061] The water vapor barrier layer 20 is composed of polyurethane polymer coating, inorganic powder, suspending agent, crosslinking agent and water in a mass ratio of 85.0:8.50:1.25:2.50:43.5;

[0062] In parts by weight, the raw material components of the inner layer 13 of the BOPLA film layer 10 include 85.0 parts of crystalline polylactic acid slices, 14.4 parts of non-crystalline polylactic acid slices, 0.50 parts of opening agent and 0.10 parts of smooth agent; the core layer 12 is composed of crystalline polylactic acid slices; the raw material components of the surface layer 11 include 90.0 parts of crystalline polylactic acid slices, 9.4 parts of non-crystalline polylactic acid slices, 0.50 parts of opening agent and 0.10 parts of slip agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com