Intelligent temperature control adhesive tape and production process thereof

An intelligent temperature control and tape technology, applied in adhesives, epoxy resin adhesives, film/sheet adhesives, etc., can solve the problems of restricting the use of temperature control tapes, insensitivity to discoloration, etc. The effect of improving the dispersing function and improving the discoloration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

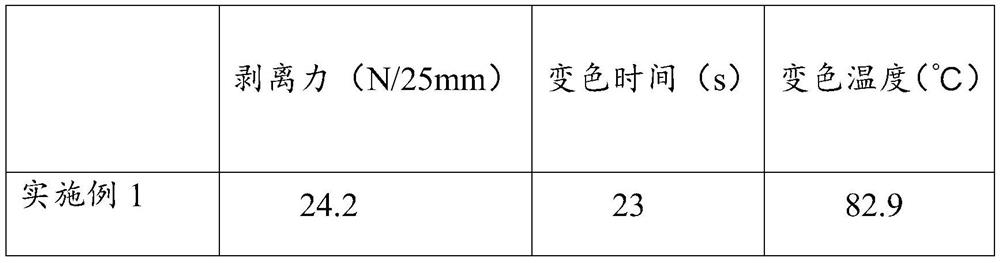

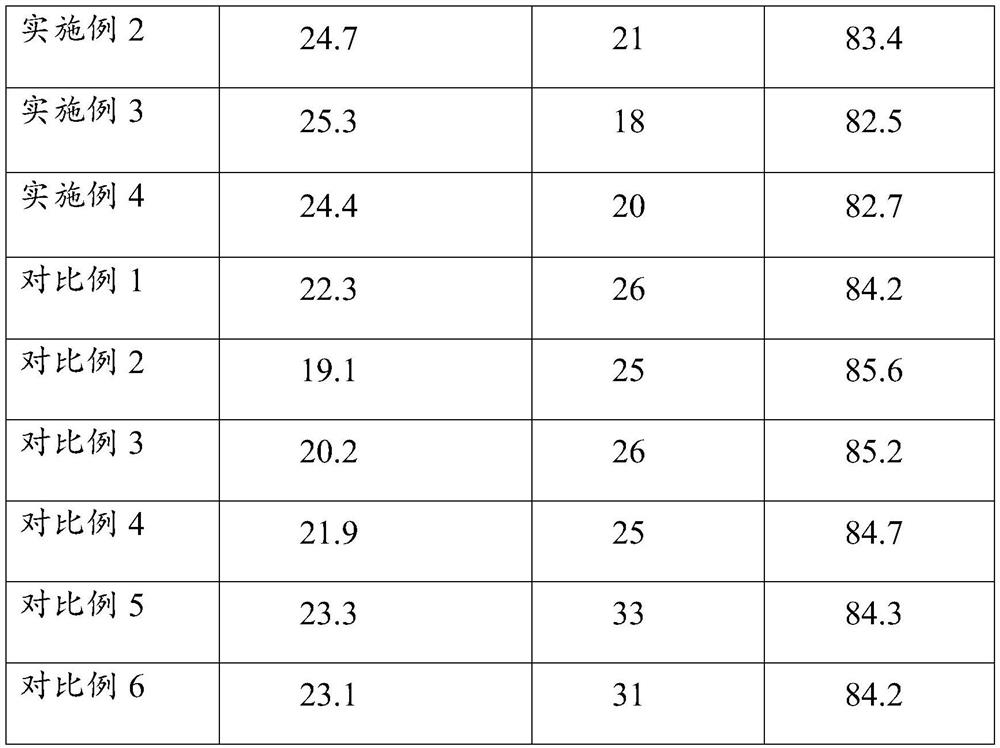

Examples

Embodiment 1

[0034] The intelligent temperature control tape of this embodiment includes a tape base, and an adhesive layer is coated on the tape base;

[0035] The adhesive layer comprises the following raw materials in parts by weight:

[0036] 40 parts of epoxy resin, 10 parts of cross-linking modification solution, 5 parts of modified heat-sensitive material, 3 parts of polyester polyol, 1 part of polyethylene glycol, and 1 part of rare earth solution.

[0037] The preparation method of the cross-linking modification liquid of the present embodiment is:

[0038] Mix divinylbenzene and amino silicone oil in a weight ratio of 1:3, then add modified soybean protein powder with 20% of the total amount of divinylbenzene, stir at a speed of 100r / min for 20min, and then add the total amount of divinylbenzene Measure 1% of azobisisobutyronitrile, continue to stir for 10 minutes, and after the stirring is completed, a cross-linking modified liquid is obtained.

[0039] The modification method...

Embodiment 2

[0055]The intelligent temperature control tape of this embodiment includes a tape base, and an adhesive layer is coated on the tape base;

[0056] The adhesive layer comprises the following raw materials in parts by weight:

[0057] 50 parts of epoxy resin, 20 parts of cross-linking modification solution, 10 parts of modified heat-sensitive material, 6 parts of polyester polyol, 5 parts of polyethylene glycol, and 2 parts of rare earth solution.

[0058] The preparation method of the cross-linking modification liquid of the present embodiment is:

[0059] Mix divinylbenzene and amino silicone oil in a weight ratio of 1:3, then add modified soybean protein powder with 30% of the total amount of divinylbenzene, stir at a speed of 200r / min for 30min, and then add the total amount of divinylbenzene Measure 5% azobisisobutyronitrile, continue to stir for 20 minutes, and after the stirring is completed, a cross-linking modified liquid is obtained.

[0060] The modification method ...

Embodiment 3

[0076] The intelligent temperature control tape of this embodiment includes a tape base, and an adhesive layer is coated on the tape base;

[0077] The adhesive layer comprises the following raw materials in parts by weight:

[0078] 45 parts of epoxy resin, 15 parts of cross-linking modification solution, 7.5 parts of modified heat-sensitive material, 4.5 parts of polyester polyol, 2 parts of polyethylene glycol, and 1.5 parts of rare earth solution.

[0079] The preparation method of the cross-linking modification liquid of the present embodiment is:

[0080] Mix divinylbenzene and amino silicone oil in a weight ratio of 1:3, then add modified soybean protein powder with 25% of the total amount of divinylbenzene, stir at a speed of 150r / min for 25min, and then add the total amount of divinylbenzene Measure 1-5% azobisisobutyronitrile, continue to stir for 15 minutes, and obtain a cross-linking modified liquid after the stirring is completed.

[0081] The modification metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com