Semiconductor material annealing device and annealing method

An annealing device, semiconductor technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, metal material coating process, etc., can solve the problems of low annealing efficiency, high energy consumption, etc., and achieve the effect of simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

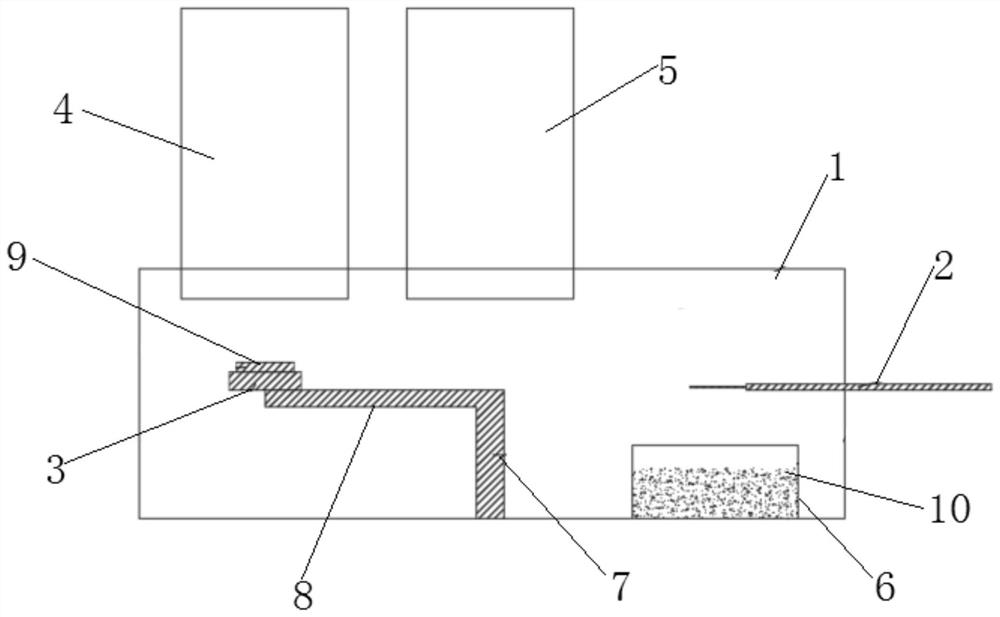

[0038] combined with Figure 1-2 , the present embodiment provides a semiconductor material annealing device, comprising: a transfer chamber 1, a sample loading platform 3 is provided in the transfer chamber 1, a sample transfer device 2 is movable on the transfer chamber 1, and the sample transfer device 2 is used for placing and removing the sample 9 on the sample loading platform 3; the first heating chamber 4, the first heating chamber 4 communicates with the transfer chamber 1, and the first heating chamber 4 is used for performing the sample 9 Pyrolysis treatment; the second heating chamber 5, the second heating chamber 5 communicates with the transfer chamber 1, the second heating chamber 5 is used to anneal the sample 9; the cooling chamber 6, the cooling chamber 6 communicates with the transfer chamber 1, the cooling chamber 6 is used to cool the sample 9 processed in the first heating chamber 4 or the second heating chamber 5; the rotating lifting mechanism, the rota...

Embodiment 2

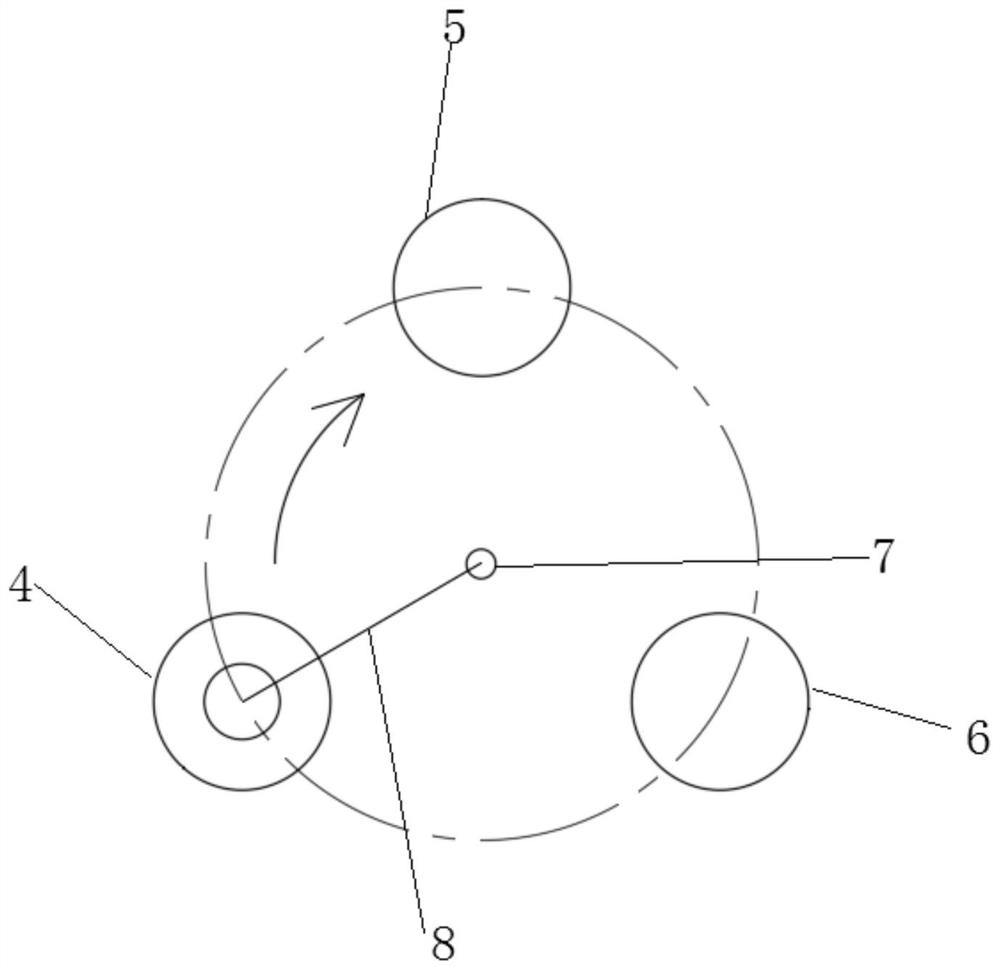

[0045] combined with figure 2 , a semiconductor material annealing device of this embodiment, compared with the technical solution of Embodiment 1, the centers of the first heating chamber 4, the second heating chamber 5 and the cooling chamber 6 are projected onto the same plane , the centers of the first heating chamber 4 , the second heating chamber 5 and the cooling chamber 6 are uniformly distributed in a manner of concentric circles.

[0046] Such as figure 2 As shown, looking down from top to bottom, the centers of the first heating chamber 4, the second heating chamber 5 and the cooling chamber 6 are projected on the same plane and evenly distributed in the form of concentric circles, so that the rotating lifting mechanism The rotation angle between the chambers can be fixed at 120°, so as to ensure the accuracy of the rotation positioning of the rotary lifting mechanism and reduce the positioning error; and this setting keeps a certain effective distance between ea...

Embodiment 3

[0048] combined with Figure 1-2 , a semiconductor material annealing device of this embodiment, compared with the technical solution of Embodiment 2, the rotary lifting mechanism includes a vertical support structure 7 and a horizontal support structure 8, and the vertical support structure 7 and the horizontal support structure The support structure 8 is vertically connected, and the vertical support structure 7 is located at the center of the concentric circle between the centers of the first heating chamber 4, the second heating chamber 5 and the cooling chamber 6, and the sample loading platform 3 is located at On the horizontal support structure 8 , and the position of the sample loading platform 3 on the horizontal support structure 8 corresponds to the center of the first heating chamber 4 , the second heating chamber 5 and the cooling chamber 6 .

[0049] Such as figure 2 As shown, looking down from top to bottom, take the position of the vertical support structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com