Differential device

A differential device and differential rotation technology, applied in the direction of differential transmission, transmission, power device, etc., can solve the problems of complex device structure, increased device volume, complex structure, etc., and achieve a compact and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0145] Embodiments of the present invention will be described with reference to the drawings. In addition, embodiment shown below is just an example of the case where this invention was actualized, and does not limit this invention.

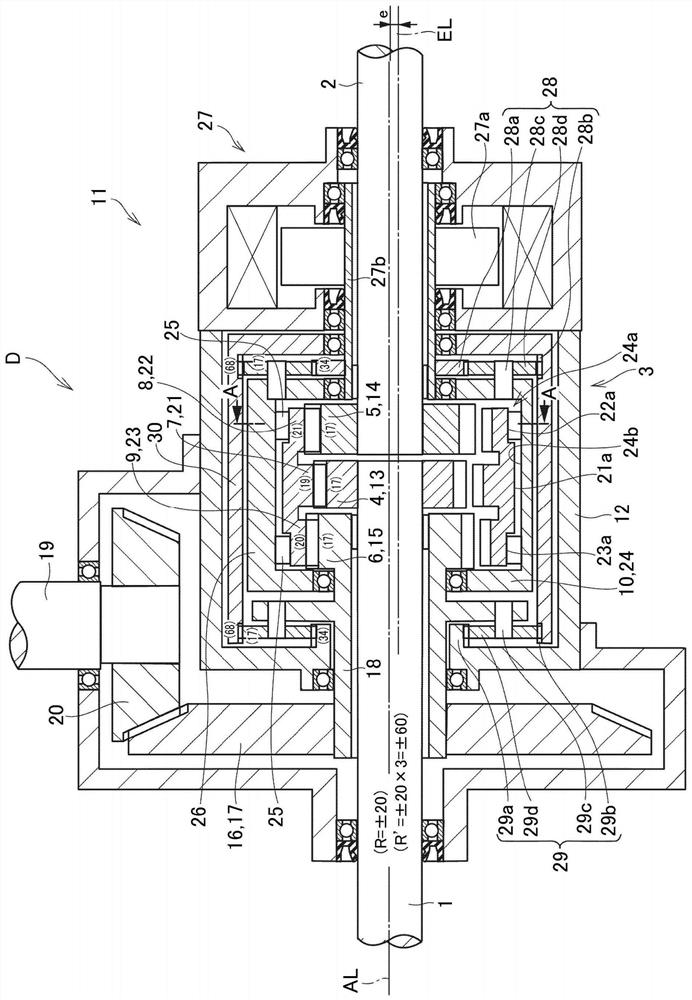

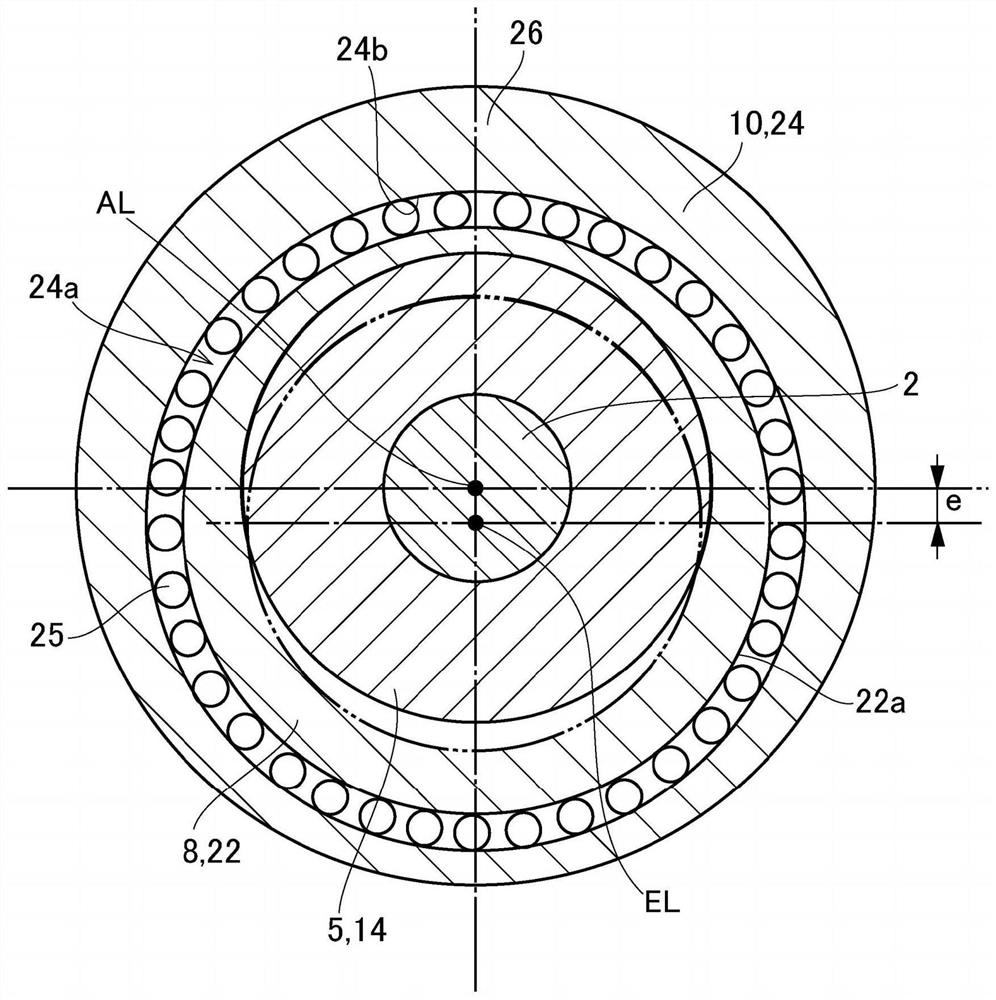

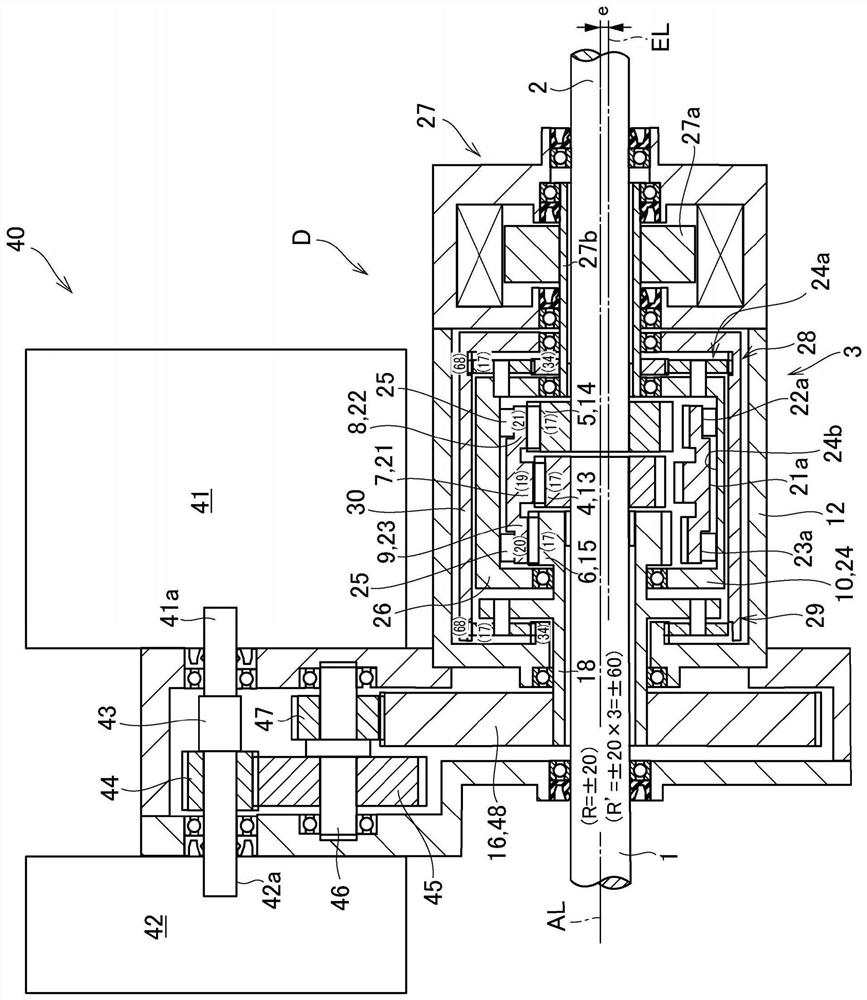

[0146] figure 1 An example of a differential device to which the present invention is applied is shown. The differential device D in the embodiment of the present invention is a transmission device configured to allow two rotating shafts arranged on the same axis to reverse each other and perform differential rotation. The first rotating shaft 1 and the second rotating shaft 2 These two main rotation shafts and the differential rotation mechanism 3 constitute. The differential rotation mechanism 3 includes a first gear 4 , a second gear 5 , a third gear 6 , a first eccentric gear 7 , a second eccentric gear 8 , a third eccentric gear 9 , and an eccentric member 10 as main components. In particular, assuming that it is mounted on a vehicle, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com