Process for reducing heavy tail fraction formation and catalyst loss in hydroformylation processes

A technology for hydroformylation and heavy-end fractions, which is used in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

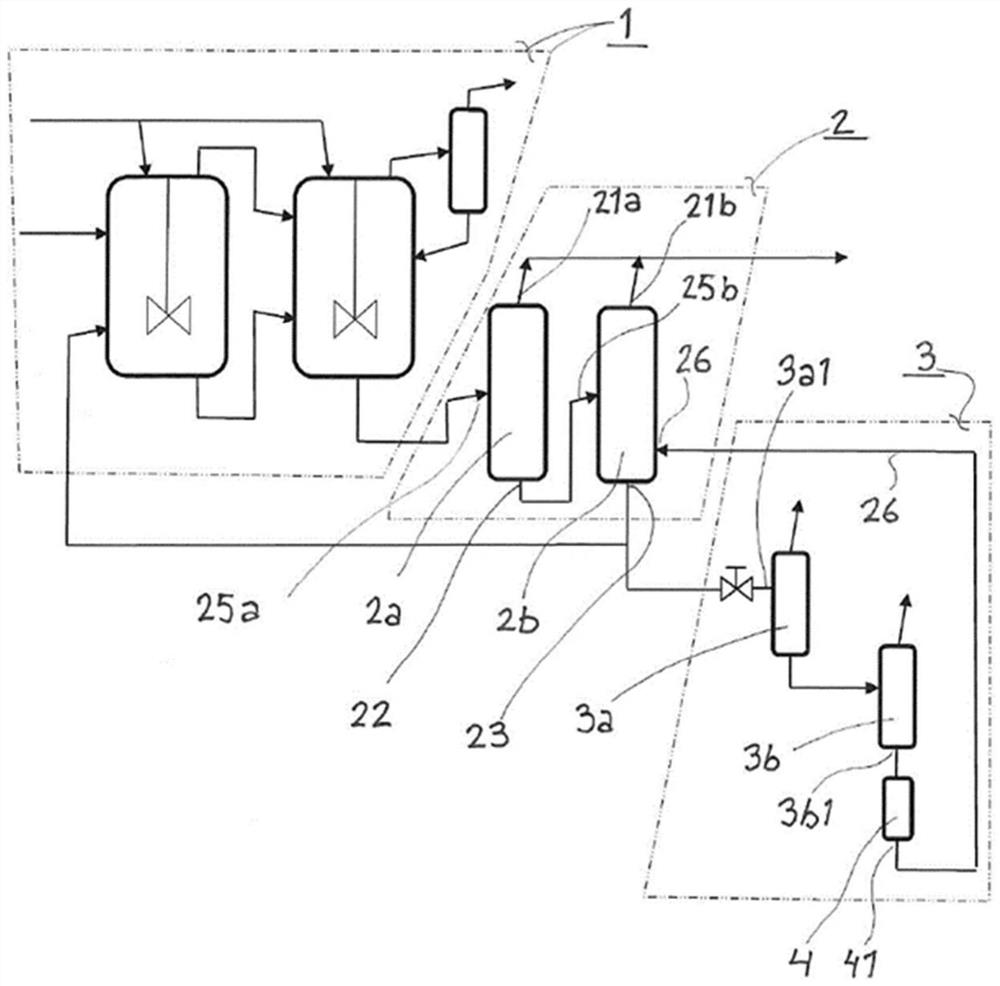

Method used

Image

Examples

Embodiment 1

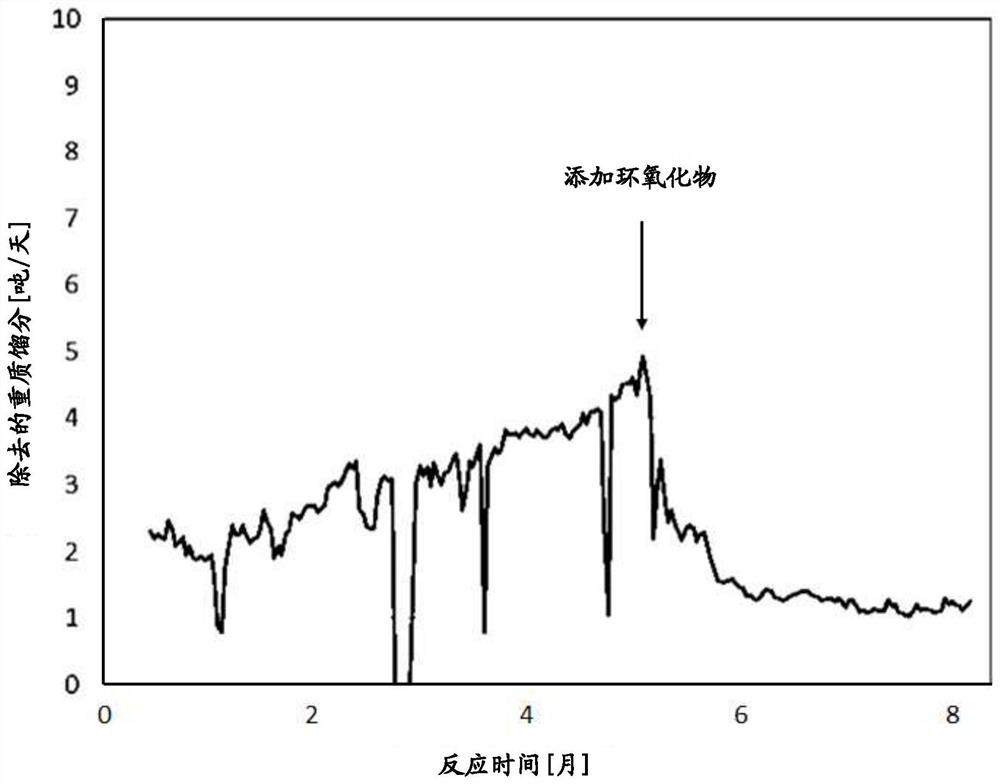

[0048] Example 1 illustrates the reduction in heavy ends formation when the process of the present invention is applied to a hydroformylation reaction mixture in a commercial process plant.

Embodiment 2

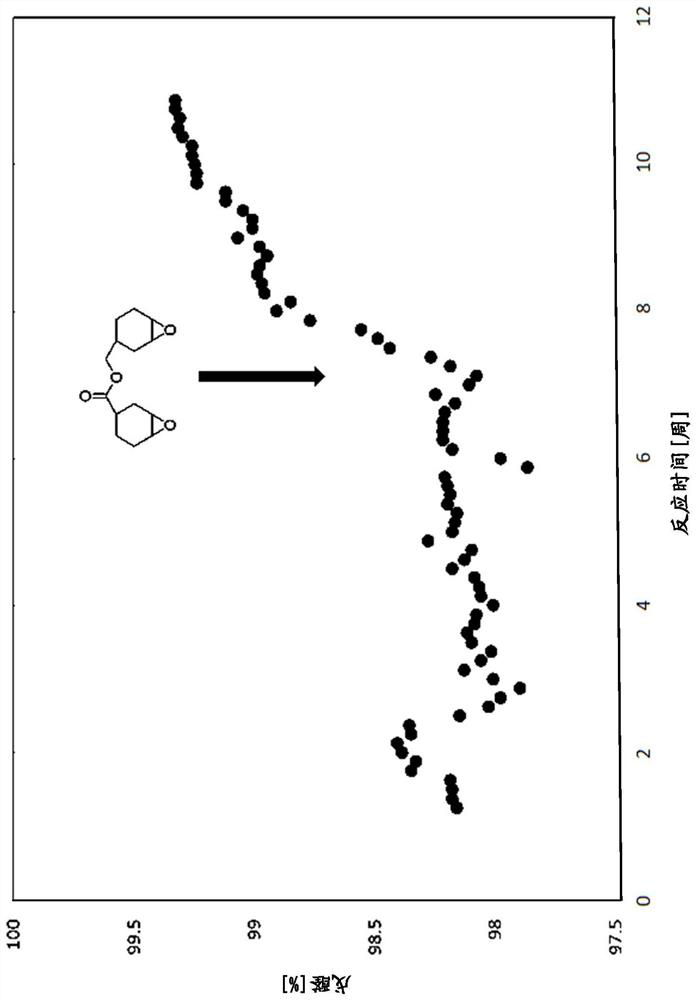

[0049] Example 2 illustrates the increased purity of the aldehyde product when the process of the present invention is applied to a hydroformylation reaction mixture in a commercial process facility.

Embodiment 3

[0050] Example 3 illustrates the effect of the process of the invention on a pilot scale, demonstrating a reduction in the rate of formation of heavy ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com