Acid-base neutralization reaction chemical sewage treatment system based on CaCO3

A chemical sewage and treatment system technology, applied in the direction of neutralizing water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of unfavorable sewage treatment, energy consumption, large power consumption, etc. Achieve the effects of improving sewage treatment speed, speeding up reaction speed, and improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description. For the step numbers in the embodiment of the present invention, it is only set for the convenience of explanation and description, and there is no limitation on the order of the steps. The execution order of each step in the embodiment can be carried out according to the understanding of those skilled in the art Adaptive adjustments:

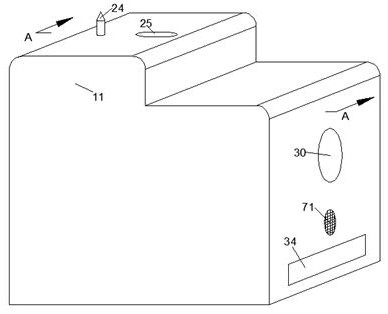

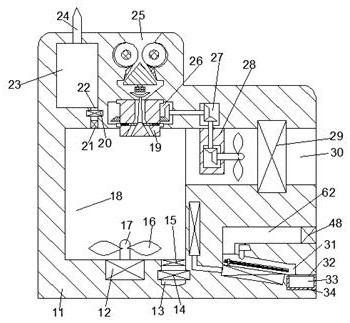

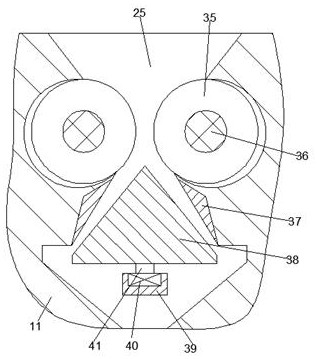

[0032] Refer to attached figure 1 — Figure 7 According to an embodiment of the present invention, a CaCO3-based acid-base neutralization reaction chemical sewage treatment system includes a body shell 11, a reaction chamber 18 is provided in the body shell 11, and a reaction chamber 18 is installed in the bottom wall The first motor 12, the first transmission shaft 17 is installed on the upper end of the first motor 12, the first paddle 16 is fixed on the first transmission shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com