Hydroponic nutrient solution for adult tomatoes and preparation method of hydroponic nutrient solution

A hydroponic nutrient solution and adulthood technology, applied in the field of tomato nutrient solution, can solve the problems of uneven quality of nutrient solution, imperfect localization of nutrient solution, low tomato yield and quality, etc., to promote normal growth and normal operation , Improve the effect of selective absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

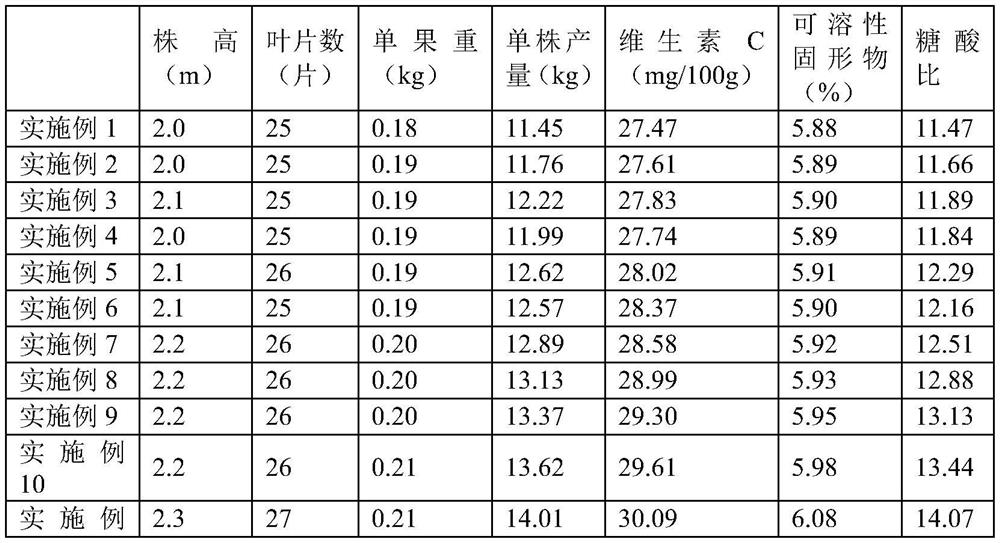

Examples

preparation example 1-3

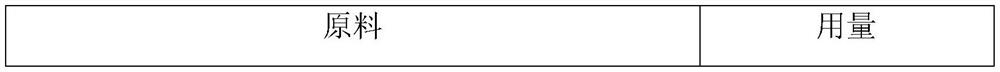

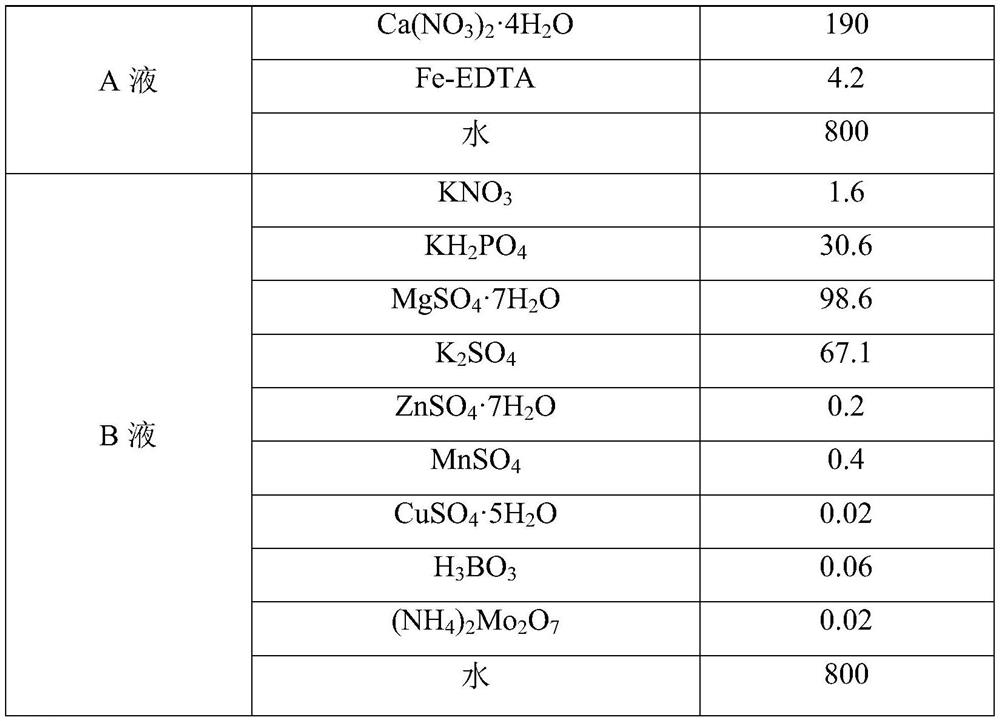

[0036] A kind of A liquid of preparation example 1-3, its each raw material and each raw material consumption are as shown in table 1, and its preparation steps are as follows:

[0037] Weigh each raw material according to the dosage in Table 1, and then stir each raw material evenly to obtain liquid A.

[0038] The A liquid raw material of table 1 preparation example 1-3 and each raw material consumption (kg)

[0039] raw material Preparation Example 1 Preparation example 2 Preparation example 3 Ca(NO 3 ) 2 4H 2 o

preparation example 4-6

[0041] A kind of B liquid of preparation example 4-6, its each raw material and each raw material consumption are as shown in table 2, and its preparation steps are as follows:

[0042] Weigh each raw material according to the dosage in Table 2, and then stir each raw material evenly to obtain liquid B.

[0043] The B liquid raw material of table 2 preparation example 4-6 and each raw material consumption (kg)

[0044] raw material Preparation Example 4 Preparation Example 5 Preparation Example 6 KNO 3

preparation example 7-9

[0046] A kind of compound sodium nitrophenolate of preparation example 7-9, its each raw material and each raw material consumption are as shown in table 3, and its preparation steps are as follows:

[0047] Weigh each raw material according to the amount in Table 3, and then stir each raw material evenly to obtain sodium nitrophenolate.

[0048] The complex sodium nitrophenolate raw material of table 3 preparation example 7-9 and each raw material consumption (kg)

[0049] raw material Preparation Example 7 Preparation example 8 Preparation Example 9 Sodium 5-Nitroguaiacol 10 15 20 sodium o-nitrophenolate 40 30 20 Sodium p-nitrophenolate 30 45 60

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com