Method for synthesizing straight-chain octadecanedioic acid

An octadecanedioic acid and straight-chain technology, applied in the field of synthesizing straight-chain octadecanedioic acid, can solve the problems of complex process, inability to industrialize production, and high cost of synthesizing straight-chain octadecanedioic acid, and achieve simple raw materials, Easy mass production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

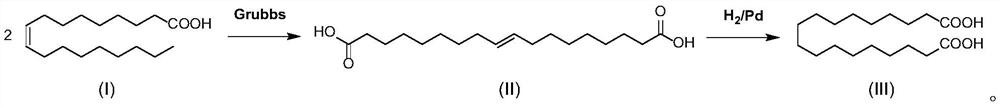

[0029] This embodiment provides a method for synthesizing linear octadecanedioic acid, comprising:

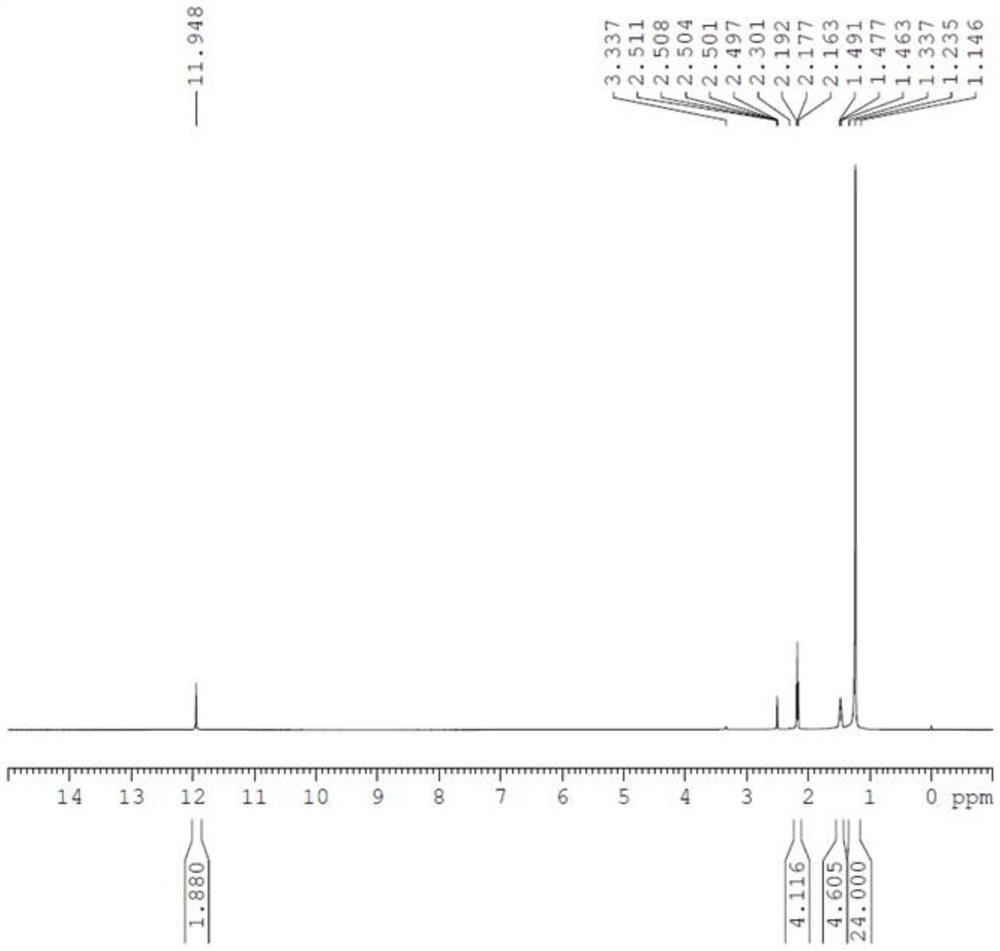

[0030] a) Under nitrogen protection, add 2340.0 kg of n-heptane, 600.0 kg of oleic acid, and 1.0 kg of Grubbs (II) catalyst into a 5000L glass-lined reactor, stir and heat up to 35-45°C. Insulated and reacted for 5 hours, then cooled to room temperature 20-25 ° C, centrifuged, the filter cake was washed with 160.0 kg of n-heptane, and the filter cake was dried to obtain 260.0 kg of the compound shown in formula II (9-octadecenedioic acid) , yield 78.4%;

[0031] b) Under nitrogen protection, add 3000.0 kg of tetrahydrofuran and 260.0 kg of the compound represented by formula II into a 5000L glass-lined reactor. After stirring to dissolve, the solution was transferred to a 5000L hydrogenation tank. 18.0 kg of 5% wet palladium carbon was added to the hydrogenation kettle, and after nitrogen replacement, hydrogen replacement was carried out to keep the pressure in the kettle at ...

Embodiment 2

[0033] This embodiment provides a method for synthesizing linear octadecanedioic acid, comprising:

[0034] a) Under nitrogen protection, add 1200.0 kg of n-heptane, 300.0 kg of oleic acid, and 0.6 kg of Grubbs (II) catalyst into a 3000L glass-lined reactor; stir and heat up to 40-50°C. Insulate and react for 4 hours, then cool down to room temperature 20-25°C, centrifuge, wash the filter cake with 160.0kg n-heptane, and dry the filter cake to obtain 140.0kg of the compound (9-octadecenedioic acid) shown in formula II , yield 84.4%.

[0035] b) Under nitrogen protection, add 2000.0 kg of tetrahydrofuran and 180.0 kg of the compound represented by formula II into a 5000L glass-lined reactor. After stirring and dissolving, transfer to a 5000L hydrogenation tank. Then add 15.0 kg of 5% wet palladium carbon to the hydrogenation kettle; after nitrogen replacement, hydrogen replacement is carried out to keep the pressure in the kettle at 0.3-0.6 bar, stir and raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com