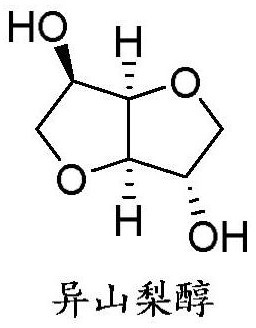

A kind of isosorbide modified high heat-resistant biodegradable polyester and preparation method thereof

A biodegradable polyester and isosorbide technology, applied in the field of polyester materials, can solve the problems of non-biodegradability and achieve high isosorbide grafting rate, good color, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of high heat-resistant biodegradable polyester, comprising the following steps:

[0050] 1) Esterification: terephthalic acid and / or dialkyl terephthalate, 40-60% straight chain aliphatic diol, isosorbide, catalyst and stabilizer are added to the reactor , remove the air in the reactor with an inert gas and then heat up to 230-260 ° C, carry out the first-stage esterification reaction under 3MPa pressure until there is no distillate; then cool down to 150-210 ° C, add direct Chain fatty dicarboxylic acid and / or its dialkyl ester and / or its acid anhydride, and the remaining linear aliphatic diol, continue to esterify under normal pressure until the amount of distillate reaches more than 90% of the theoretical value, then proceed to the next step polycondensation reaction.

[0051] 2) Polycondensation reaction: after the esterification reaction is completed, slowly evacuate, remove the excess diol, make the vacuum degree within 60Pa after 50-70min, w...

Embodiment 1

[0054] 1) Esterification: 664.52g terephthalic acid, 121.04g ethylene glycol, 374.12g isosorbide, 0.016g stannous isooctoate and 0.21g trimethyl phosphate were added to the 2.5L reactor, and nitrogen was used to remove The air in the reactor is then heated up to 260°C to carry out the first-stage esterification reaction until there is no distillate; then the temperature is lowered to 210°C, and 118.09g of succinic acid and the remaining 121.04g of ethylene glycol are added under nitrogen protection, usually Continue esterification under pressure until the amount of distillate reaches more than 90% of the theoretical value.

[0055] 2) Polycondensation reaction: After the esterification reaction is completed, slowly vacuumize to remove excess diol, and the vacuum degree reaches the maximum in about 1h. While evacuating, the temperature was raised to 220°C. Continue to keep the vacuum degree below 60Pa for the reaction, and discharge the material after the reaction is completed...

Embodiment 2

[0057] 1) esterification reaction: 776.72g of dimethyl terephthalate, 121.04g of ethylene glycol, 374.12g of isosorbide, 0.016g of stannous isooctoate and 0.21g of trimethyl phosphate were added to the 2.5L reactor, After removing the air in the reactor with nitrogen, the temperature was raised to 250°C to carry out the first-stage esterification reaction until there was no distillate; then the temperature was lowered to 210°C, and 118.09g of succinic acid and the remaining 121.04g of ethylene glycol were added under the protection of nitrogen. alcohol, and continue to esterify under normal pressure until the amount of distillate reaches more than 90% of the theoretical value.

[0058] 2) Polycondensation reaction: After the esterification reaction is completed, slowly vacuumize to remove excess diol, and the vacuum degree reaches the maximum in about 1h. While evacuating, the temperature was raised to 220°C. Continue to keep the vacuum degree below 60Pa for the reaction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com