OLED (Organic Light Emitting Diode) display screen light-emitting coating protection filling adhesive and preparation method thereof

A technology for protecting filling and display screens, applied in the direction of adhesives, epoxy glue, adhesive types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

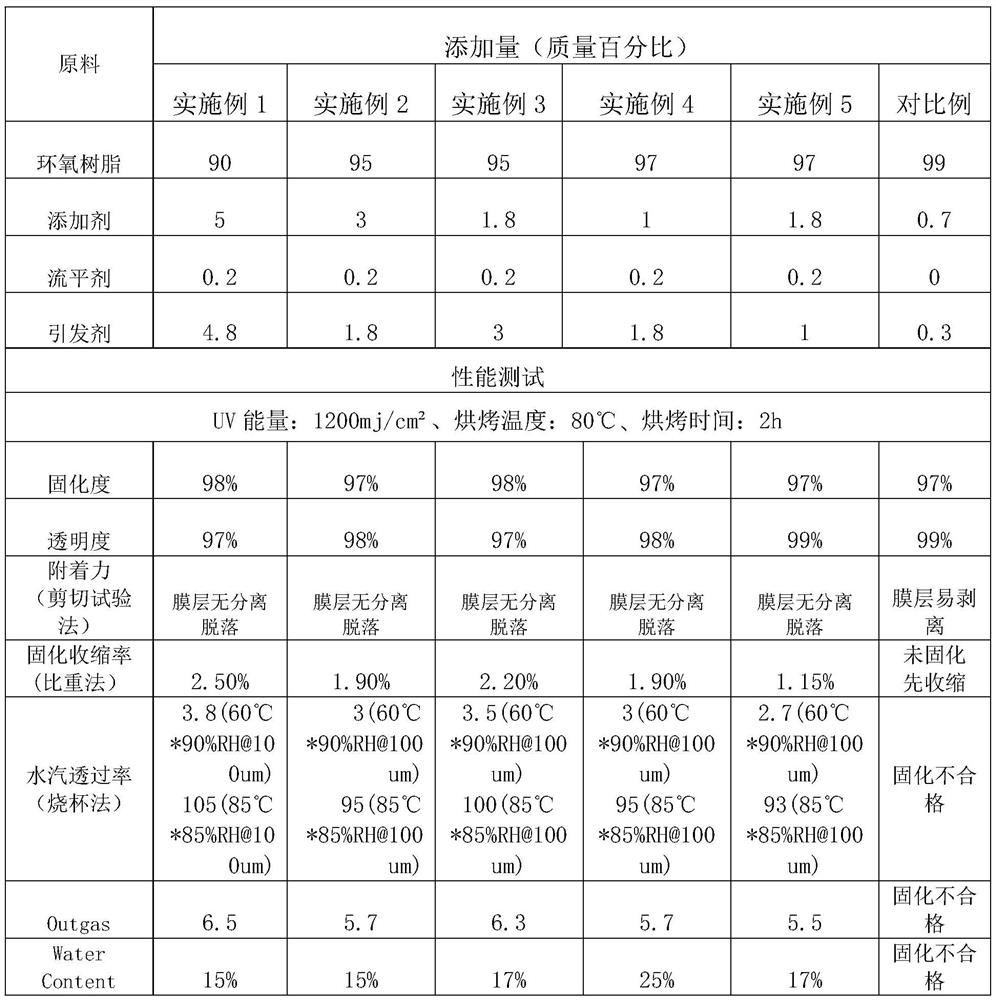

Examples

preparation example Construction

[0032] A method for preparing an OLED display luminous coating protection filler, comprising the following steps:

[0033] (1) Clean the cavity, dispersing disc, and stirring rod of the reactor A with ethyl acetate, and return to the original sealed state after the cleaning is completed;

[0034] (2) Vacuumize the sealed reaction kettle to remove water vapor, and the vacuum degree must reach 1.0×10 -4 Torr;

[0035] (3) After the vacuum operation is completed, inject nitrogen into the reactor A to release the pressure and return to normal atmospheric pressure;

[0036] (4) Add epoxy resin and initiator, after primary dispersion with 300 rpm speed, start ultrasonic oscillation, increase stirring speed to 1200 rpm for high-speed dispersion, dispersion time 20 minutes;

[0037] (5) After step (4) is completed, stop the ultrasonic oscillation, add additives, and disperse at a speed of 800 rpm for 5 minutes;

[0038] (6) After step (5) is completed, add leveling agent and defoam...

Embodiment 1

[0043] The invention provides a protective filling glue for OLED display luminous coating, which comprises the following components: in terms of mass percentage, epoxy resin is 90%, additive is 5%, initiator is 4.8%, and leveling agent is 0.2%. The initiator is the composition of 4-(phenylthio)phenyl diphenylthiohexafluorophosphate, bis(4-(diphenylsulfonium)phenyl)sulfide-bishexafluorophosphate; The oxygen resin is a combination of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate and epoxybutane. The leveling agent is polydimethylsiloxane.

[0044] A method for preparing an OLED display luminous coating protection filler, comprising the following steps:

[0045] (1) Clean the cavity, dispersing disc, and stirring rod of the reactor A with ethyl acetate, and return to the original sealed state after the cleaning is completed;

[0046] (2) Vacuumize the sealed reaction kettle to remove water vapor, and the vacuum degree must reach 1.0×10 -4 Torr;

[0047] (3) After ...

Embodiment 2

[0055] The invention provides a protective filling glue for OLED display luminescent coating, which comprises the following components: in terms of mass percentage, epoxy resin is 95%, additive is 3%, initiator is 1.8%, and leveling agent is 0.2%. The initiator is 4-(phenylthio)phenyl diphenylthiohexafluorophosphate, bis(4-(diphenylsulfonium)phenyl)sulfide-bishexafluorophosphate, diphenyl-(4 -Phenylthio)phenylsulfonium hexafluoroantimonate, bis[4-diphenylthiophenyl]sulfide dihexafluoroantimonate, bis(4-tert-butylphenyl)iodonium hexafluorophosphate, Di-tert-butylphenyliodonium hexafluorophosphate mixture; the epoxy resin is 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate. The leveling agent is polydimethylsiloxane. The additives are trimethoxy[2-(7-oxabicyclo[4.1.0]hept-3-yl)ethyl]silane, 3-(2,3-epoxypropoxy)propyltrimethoxy Mixture of silanes.

[0056] A method for preparing an OLED display luminous coating protection filler, comprising the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com