A kind of non-oriented silicon steel thin strip for ultra-high-efficiency inverter air-conditioning compressor and its manufacturing method

A frequency conversion air conditioner and oriented silicon steel technology, applied in the field of non-oriented silicon steel, can solve the problems of difficulty in meeting the requirements of ultra-efficient air conditioner compressors, inability to meet the high magnetic inductance of high efficiency inverter air conditioners, and unfavorable cold-rolled forward running, etc., so as to improve the magnetic properties of products. , high yield ratio, the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

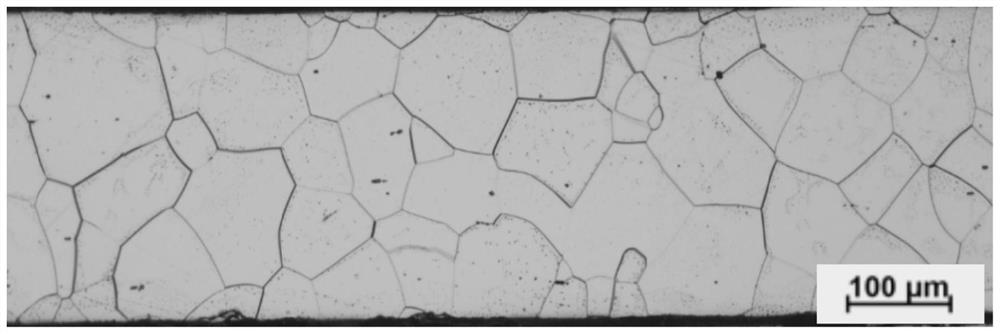

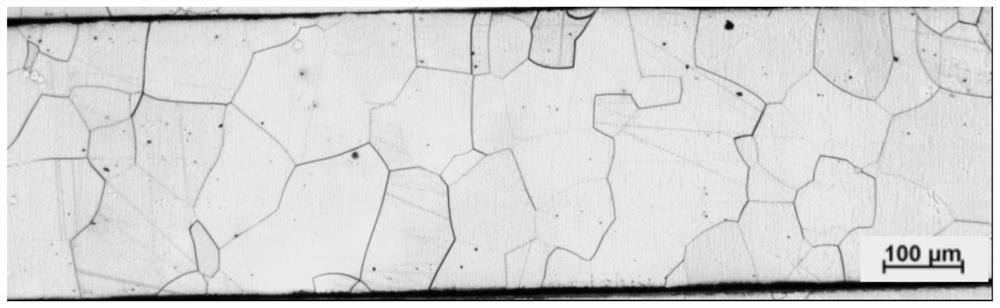

Image

Examples

Embodiment 1

[0045] A non-oriented silicon steel strip for an ultra-efficient inverter air conditioner compressor of the present embodiment includes the following components by weight: C: 0.003%, Si: 2.2%, Mn: 0.18%, Als: 0.55%, Sn: 0.10% , S: 0.003%, P: 0.02%, N: 0.002%, Ti: 0.003%, B: 0.002%, Ca: 0.004%, the rest are Fe and inevitable impurities, and the Mn / S ratio is controlled at 20-60 range, the B / N ratio is controlled within the range of 0.7 to 1.5, the Ca / S ratio is ≥1, specifically, in this embodiment, the Mn / S ratio is 60, the B / N ratio is 1, and the Ca / S ratio is 1. The ratio is 1.33. Since the Mn element can promote the strengthening of the favorable texture components and the weakening of the unfavorable texture components, the magnetic properties of the product can be further improved, and the Mn and S elements form MnS, which has a reducing effect on the solid solution of S when the slab is heated. However, if the Mn content is too high, fine MnS precipitates will be generat...

Embodiment 2

[0058] The production process of a non-oriented silicon steel thin strip for an ultra-high-efficiency inverter air conditioner compressor of this embodiment is basically the same as that of Embodiment 1, and the difference is that it includes the following components by weight: C: 0.00:2%, Si: 2.3%, Mn: 0.15%, Als: 0.55%, Sn: 0.11%, S: 0.001%, P: 0.02%, B: 0.003%, Ca: 0.003%, N: 0.002%, Ti: 0.003%, The rest are Fe and inevitable impurities, of which the ratio of Mn / S is 50, the ratio of B / N is 1.5, and the ratio of Ca / S is 3.

[0059] A method for manufacturing a non-oriented silicon steel strip for an ultra-efficient inverter air conditioner compressor in this embodiment is to cast the molten steel into a slab with a thickness of 230mm, the temperature of the heating furnace is 1100°C, and the heating and holding time is 240min.

[0060] The above-mentioned slab was rough-rolled to an intermediate billet with a thickness of 33 mm, and finished to a hot-rolled sheet with a thi...

Embodiment 3

[0064] The production process of a non-oriented silicon steel thin strip for an ultra-efficient inverter air conditioner compressor of this embodiment is basically the same as that of Embodiment 1, except that it includes the following components by weight: C: 0.003%, Si: 2.20%, Mn: 0.16%, Als: 0.25%, Sn: 0.01%, S: 0.003%, P: 0.02%, B: 0.004%, Ca: 0.004%, N: 0.003%, Ti: 0.001%, the rest are Fe and inevitable impurities, wherein the ratio of Mn / S is 53.33, the ratio of B / N is 1.33, and the ratio of Ca / S is 1.33.

[0065] In this embodiment, a method for manufacturing a non-oriented silicon steel thin strip for an ultra-efficient inverter air conditioner compressor is to cast the above-mentioned molten steel into a slab with a thickness of 220 mm, and the temperature of the first preheating section in the heating furnace is 950° C. The temperature of the second preheating section is 1000℃, the temperature of the third soaking section is 1100℃, and the heating and holding time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com