Protection device for preventing high-temperature corrosion of water cooling wall of opposed firing boiler and use method of protection device

A technology for high-temperature corrosion and protection devices, which is applied in the combustion method, combustion with multiple fuels, combustion with block fuel and liquid fuel, etc. It can solve the problem of increasing the wind rigidity of the side wall, slagging, and short service life of the water wall. and other problems, to achieve the effect of protecting the area of the water-cooled wall, increasing the area of the water-cooling wall, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

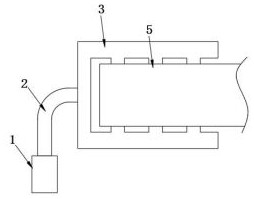

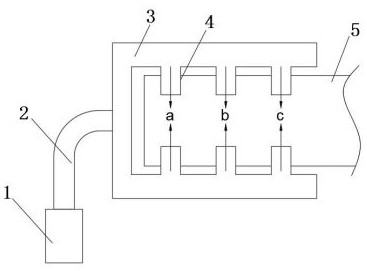

[0034] see Figure 1-8 As shown, the present invention is a protection device for preventing high temperature corrosion of the water-cooled wall of a flush boiler. One side of the device 1 is fixedly connected with an outer hot air pipe 3, and the flue gas is transported to the inside of the boiler flue 5 through the blower, and at the same time transported to the inside of the air preheater 1, and the air preheater 1 passes through the boiler flue 5. The residual heat of the flue gas heats the air and transports it to the inside of the outsourcing hot air pipe 3 through the hot air pipe 12, and the air outlet pipe 4 is arranged symmetrically inside the outsourcing hot air pipe 3, and then enters into the air outlet through the outsourcing hot air pipe 3. Inside the air outlet pipe 4, the air outlet pipe 4 acts on the inside of the boiler flue 5, such as figure 2 As shown, multiple air outlet pipes 4 are inserted into the interior of the boiler flue 5, and a represents the w...

Embodiment 2

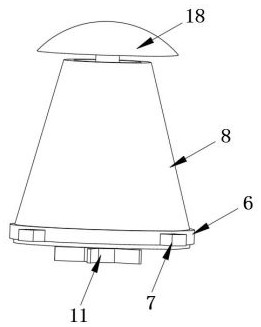

[0036] Embodiment 2: An adjustment assembly 13 is fixedly connected to the side of the driven gear plate 122 away from the positioning support plate 9, and a hollow support tube 16 is fixedly connected to the upper surface of the drive gear 15, and is inserted into the upper surface of the hollow support tube 16 There is a telescopic link 17, and the end of the telescopic link 17 away from the hollow support tube 16 is fixedly connected with a wind control shield 18, and the upper end of the hollow support tube 16 is fixedly connected with a buffer spring inside, and the other end of the buffer spring is connected to the telescopic link 17. It is fixedly connected, and the buffer spring plays a buffering effect. The upper end of the telescopic connecting rod 17 is located outside the nozzle protection shell 8, and with the rotation of the driven gear plate 122, the adjustment assembly 13 on the driven gear plate 122 follows Carry out synchronous rotation, that is, the driven ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com