Display device

A technology for display devices and display panels, which is applied in the directions of identification devices, instruments, electrical components, etc., can solve the problems of bulging and wrinkling of edges and delamination of film layers, and achieves the effect of reducing costs and improving the rate of dismantling and repairing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

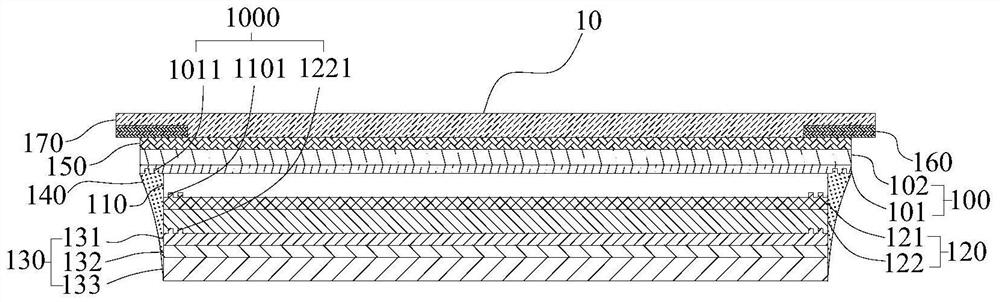

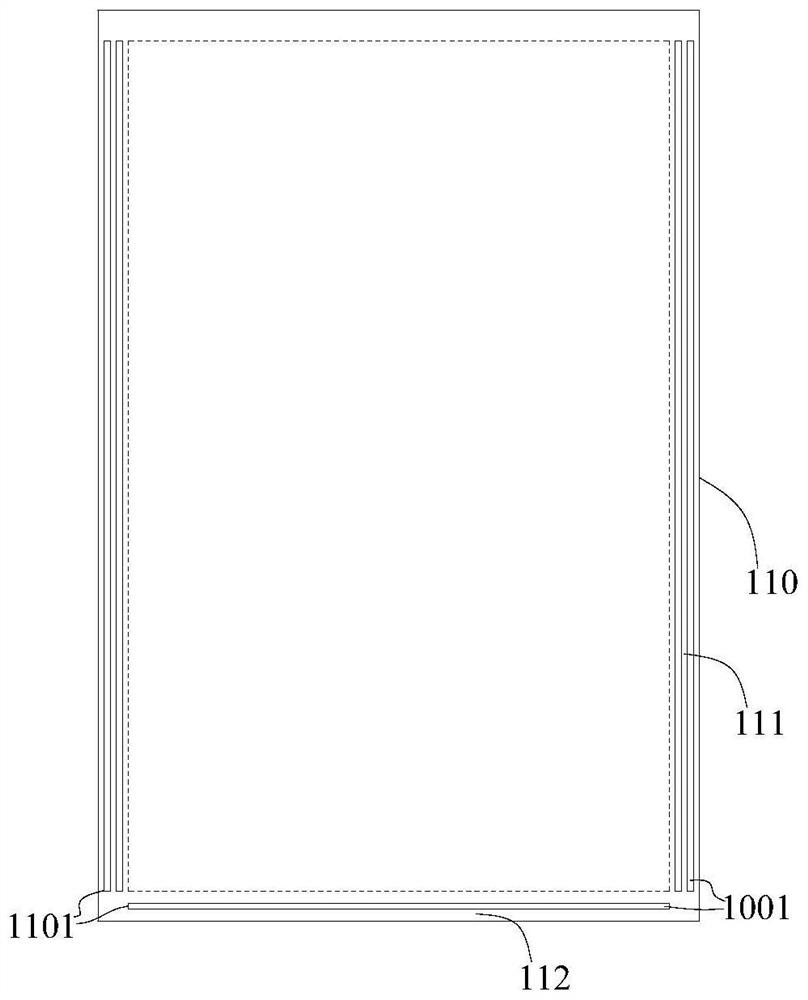

[0033] figure 1 It is a schematic structural diagram of a display device provided by Embodiment 1 of the present invention; figure 2 It is a schematic cross-sectional view of some film layers in the display device provided by Embodiment 1 of the present invention. combine figure 1 with figure 2 As shown, the present invention provides a display device 10, and the display device 10 may be a flat display device.

[0034] In this embodiment, the display device 10 includes a display panel 100, and the display panel 100 is configured to perform a display function. In this embodiment, the display panel 100 is, for example, an OLED display panel. Certainly, the present invention does not limit the type of the display panel 100 , and in other embodiments of the present application, the display panel 100 may also be a liquid crystal display panel or an inorganic light emitting diode display panel.

[0035] In this embodiment, the display panel 100 includes a base substrate 101 a...

Embodiment 2

[0062] Figure 4 A schematic diagram of the distribution of the first microstructure on the backplane provided in Embodiment 2 of the present invention, combined with figure 2 with Figure 4 As shown, Embodiment 2 of the present invention provides a display device 10. The structure of the display device 10 is similar to that of the display device 10 provided in Embodiment 1 of the present invention. This embodiment will not repeat the same parts. The difference is that the The distribution modes of the grooves 1001 in the microstructure 1000 on the display panel 100, the backplane 110 and the composite functional layer of the above-mentioned display devices are different.

[0063] Specifically, the microstructure 1000 includes the first microstructure 1101 disposed on the edge of the backplane 110, the second microstructure 1221 disposed on the edge of the composite functional layer, and the The third microstructure 1011 on the edge of the display panel 100 is described abo...

Embodiment 3

[0069] Figure 5 A schematic diagram of the distribution of the first microstructure on the backplane provided in Embodiment 3 of the present invention, combined with figure 2 with Figure 5 As shown, Embodiment 3 of the present invention provides a display device 10. The display device 10 is similar in structure to the display device 10 provided in Embodiment 1 of the present invention. This embodiment will not repeat the same parts. The difference is that the The distribution modes of the grooves 1001 in the microstructure 1000 on the display panel 100, the backplane 110 and the composite functional layer of the above-mentioned display devices are different.

[0070] Specifically, the microstructure 1000 includes the first microstructure 1101 disposed on the edge of the backplane 110, the second microstructure 1221 disposed on the edge of the composite functional layer, and the The third microstructure 1011 on the edge of the display panel 100 is described above. The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com