Lithium ion battery electrolyte and preparation method and application thereof

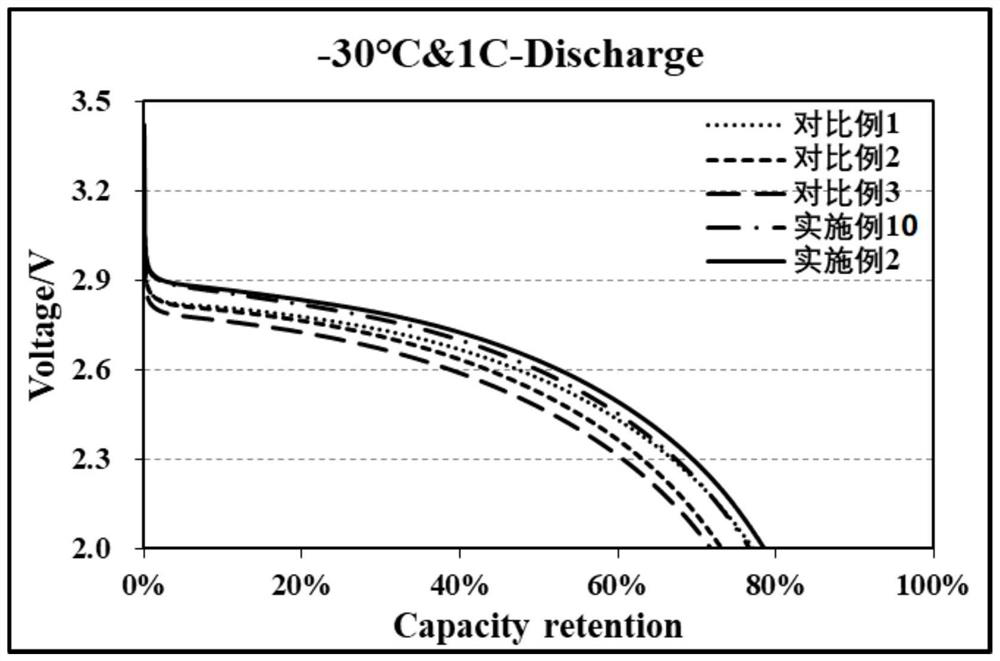

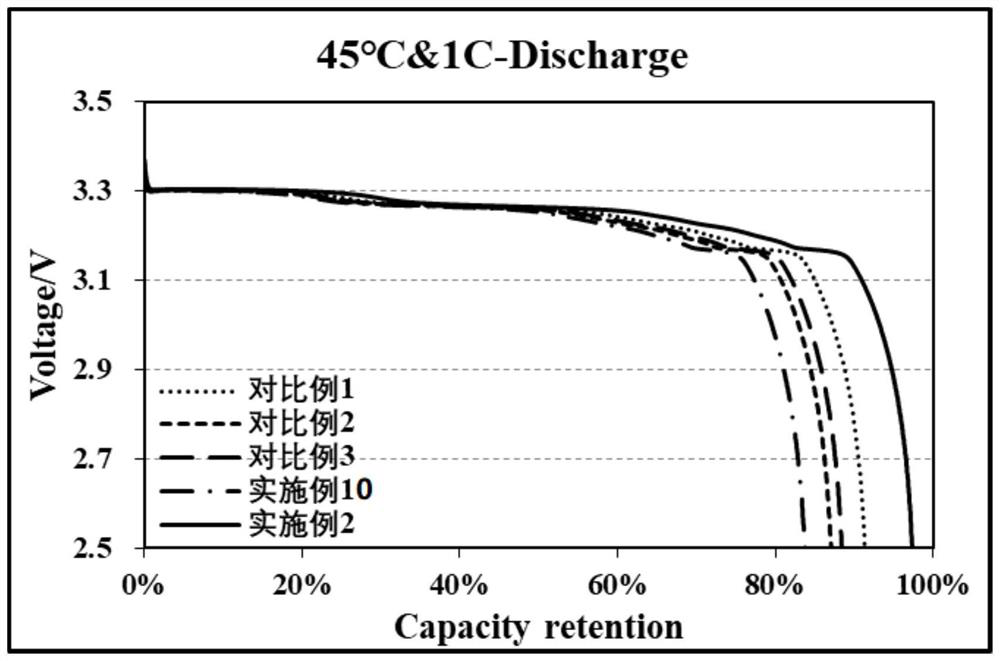

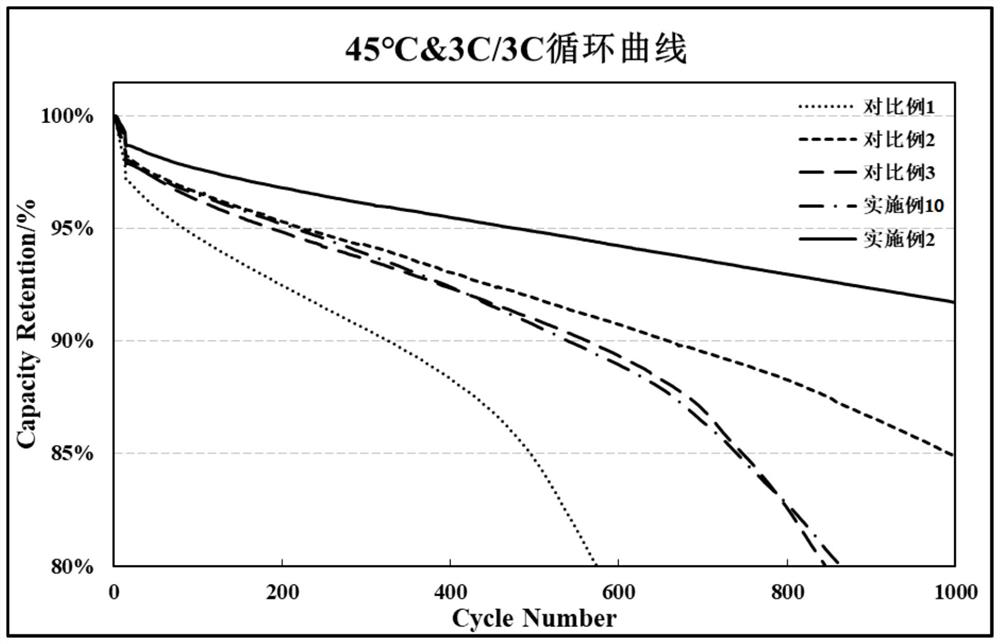

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor low-temperature discharge retention rate, short cycle life, and no beneficial effect of improving lithium-ion performance. Effect of High Discharge Capacity Retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The present embodiment provides a kind of lithium-ion battery electrolyte:

[0055] A wide temperate 12V lithium-ion battery electrolyte, lithium hexafluorophosphate 11.20%, lithium bisfluorosulfonimide 7.19%, ethylene carbonate 20.15%, propylene carbonate 4.04%, dimethyl carbonate 24.18%, Ethyl methyl carbonate 32.24%, vinylene carbonate 0.165%, ethylene ethylene carbonate 0.165%, fluoroethylene carbonate 0.165%, lithium difluorophosphate 0.34% and lithium difluorooxalate borate 0.165%.

Embodiment 2

[0057] The present embodiment provides a kind of lithium-ion battery electrolyte:

[0058] A wide temperate 12V lithium-ion battery electrolyte, lithium hexafluorophosphate 11.20%, lithium bisfluorosulfonimide 7.19%, ethylene carbonate 19.65%, propylene carbonate 3.93%, dimethyl carbonate 23.58%, Ethyl methyl carbonate 31.45%, vinylene carbonate 0.5%, ethylene ethylene carbonate 0.5%, fluoroethylene carbonate 0.5%, lithium difluorophosphate 1.0% and lithium difluorooxalate borate 0.5%.

Embodiment 3

[0060] The present embodiment provides a kind of lithium-ion battery electrolyte:

[0061] A wide temperate 12V lithium-ion battery electrolyte, lithium hexafluorophosphate 12.26%, lithium bisfluorosulfonimide 6.13%, ethylene carbonate 26.87%, dimethyl carbonate 13.435%, methyl ethyl carbonate 40.304% in the lithium battery electrolyte , vinylene carbonate 0.5%, ethylene ethylene carbonate 0.25%, fluoroethylene carbonate 0.75%, lithium difluorophosphate 1.0% and lithium difluorooxalate borate 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com