A kind of preparation method of lithium ion battery electrode containing graphene-coated single crystal positive electrode material

A graphene-coated, lithium-ion battery technology, applied in the field of preparation of lithium-ion battery electrodes, can solve the problems of battery volume energy density reduction, low stacking density, easy mutual agglomeration, etc., and achieve high-rate charge and discharge capacity retention High, high cycle capacity retention rate, excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

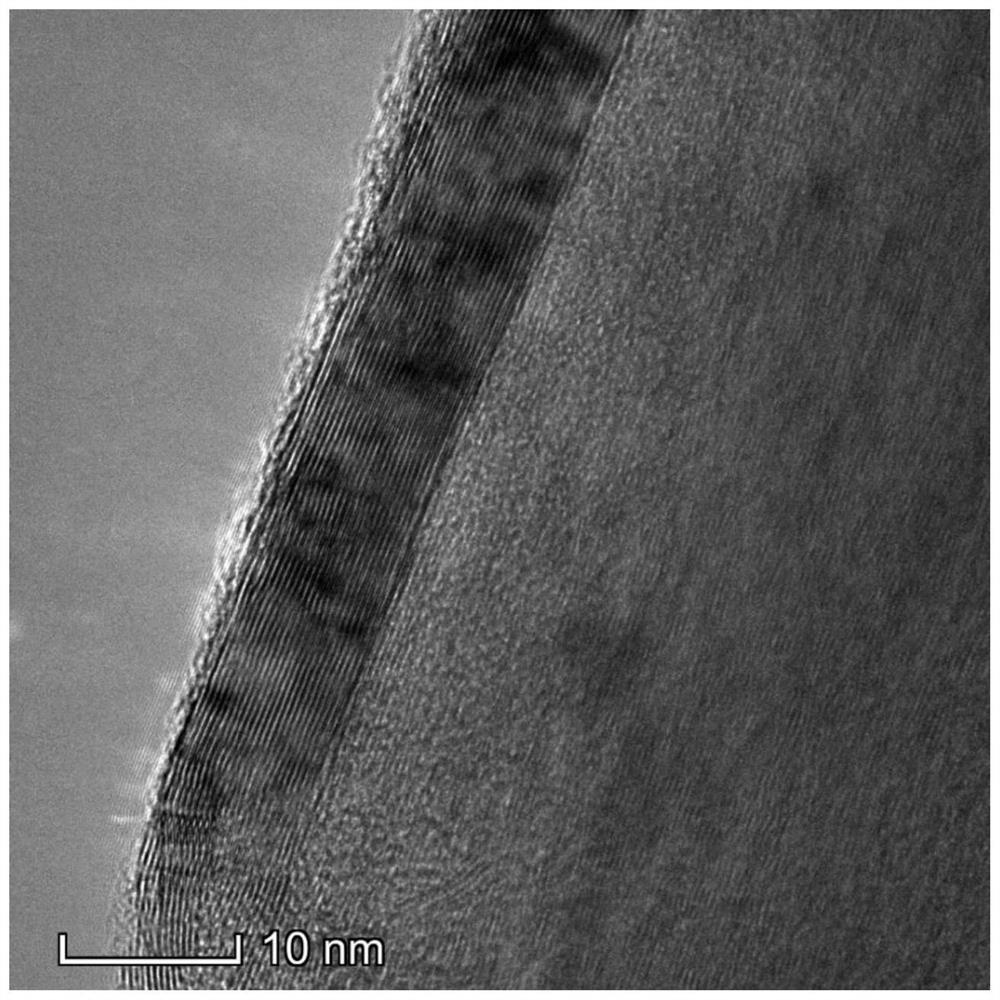

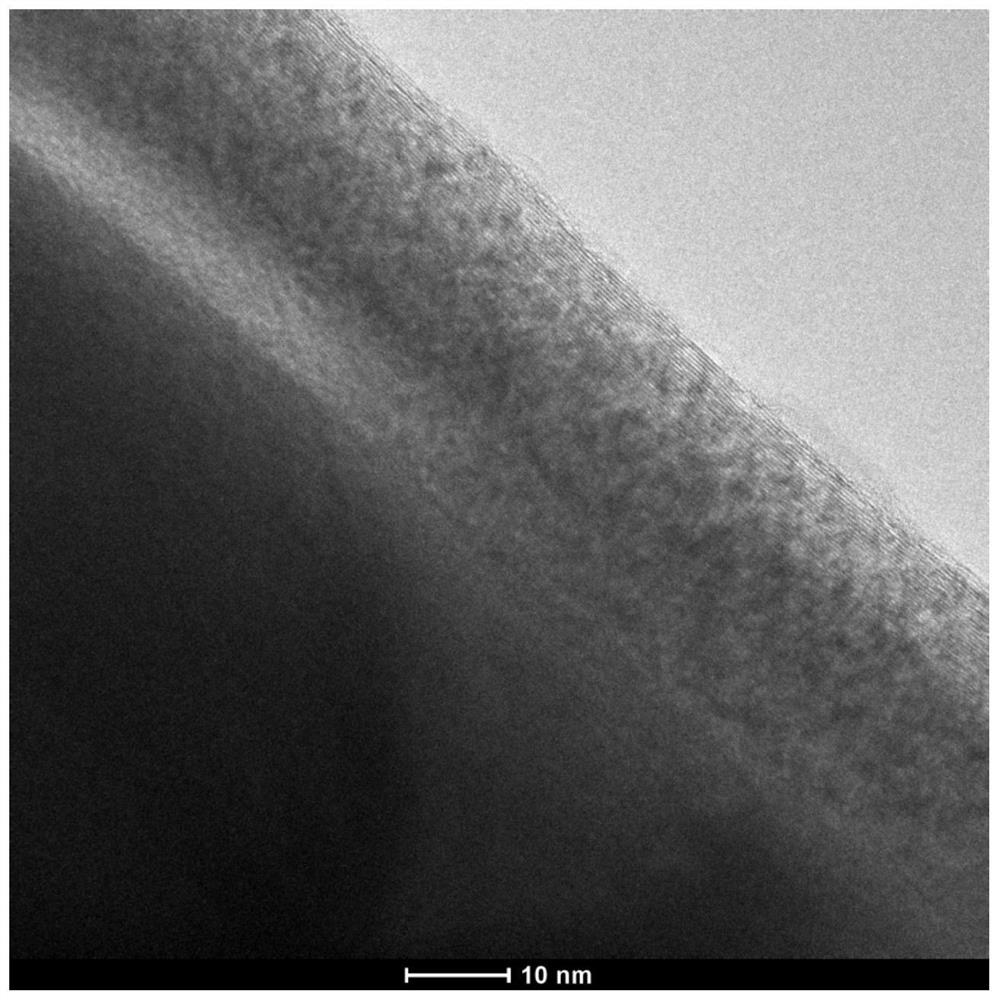

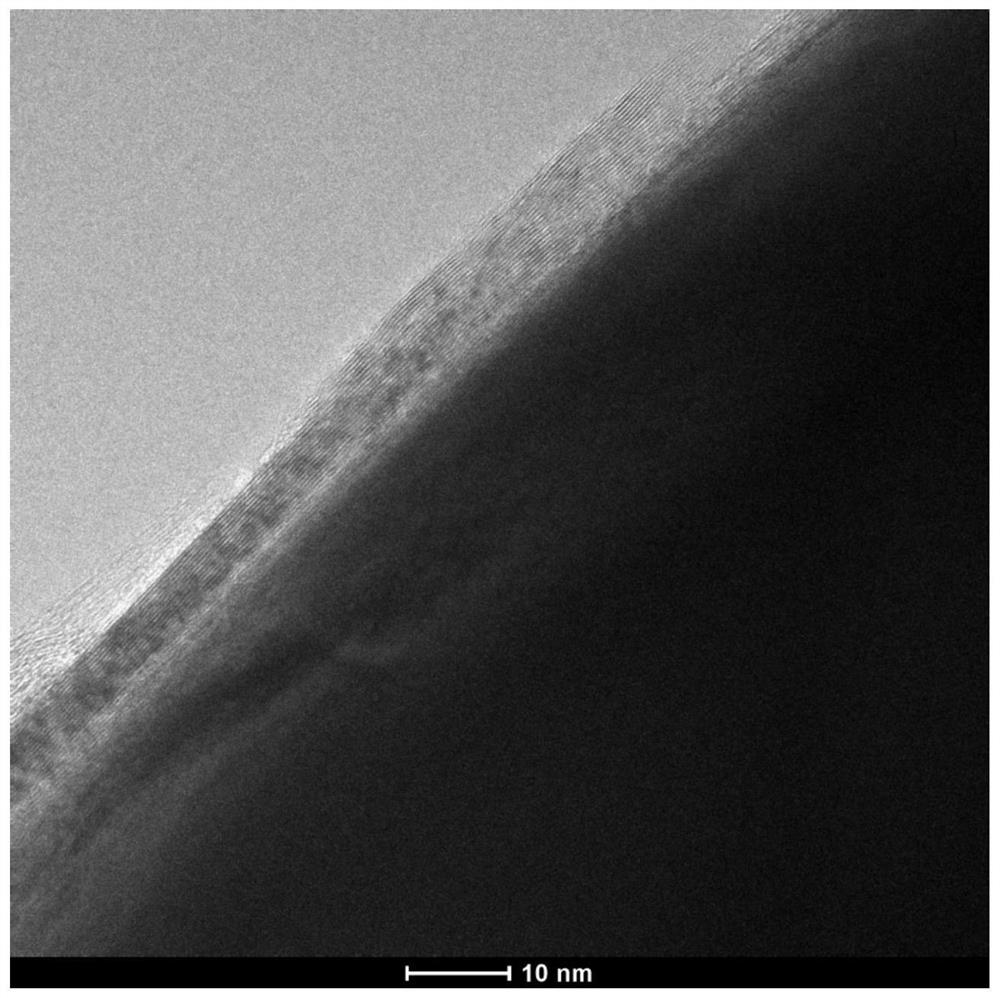

Image

Examples

Embodiment 1

[0088] Embodiment 1 provides a preparation method of a lithium battery electrode containing a graphene-coated single crystal positive electrode material, the steps include mixing the graphene-coated single crystal positive electrode material with a conductive agent and a binder and then adding N-formazol It is prepared by adjusting the solid content of base pyrrolidone to 50% and then coating it on the current collector; the graphene-coated single crystal positive electrode material, conductive agent and binder are in a mass ratio of 94:3:3; wherein, the The conductive agent is carbon black (litx200 of Cabot Company); the binding agent is polyvinylidene fluoride (HSV900 of Arkema Company); the current collector is aluminum foil (1N00-H18 of Five Star Company);

[0089] The preparation steps of the graphene-coated single crystal cathode material include: at room temperature, the binder and the solvent B are mixed according to a mass ratio of 1:9 to form an organic solvent A; the...

Embodiment 2

[0098] Embodiment 2 provides a preparation method of a lithium battery electrode containing a graphene-coated single crystal positive electrode material, the steps include mixing the graphene-coated single crystal positive electrode material with a conductive agent and a binder and then adding N-formazol It is prepared by adjusting the solid content of base pyrrolidone to 50% and then coating it on the current collector; the graphene-coated single crystal positive electrode material, conductive agent and binder are in a mass ratio of 94:3:3; wherein, the The conductive agent is carbon black (litx200 of Cabot Company); the binding agent is polyvinylidene fluoride (HSV900 of Arkema Company); the current collector is aluminum foil (1N00-H18 of Five Star Company);

[0099] The preparation steps of the graphene-coated single crystal cathode material include: at room temperature, the binder and the solvent B are mixed according to a mass ratio of 1:9 to form an organic solvent A; the...

Embodiment 3

[0108] Embodiment 3 provides a preparation method of a lithium battery electrode containing a graphene-coated single crystal positive electrode material, the steps include mixing the graphene-coated single crystal positive electrode material with a conductive agent and a binder and then adding N-formazol It is prepared by adjusting the solid content of base pyrrolidone to 50% and then coating it on the current collector; the graphene-coated single crystal positive electrode material, conductive agent and binder are in a mass ratio of 94:3:3; wherein, the The conductive agent is carbon black (litx200 of Cabot Company); the binding agent is polyvinylidene fluoride (HSV900 of Arkema Company); the current collector is aluminum foil (1N00-H18 of Five Star Company);

[0109]The preparation steps of the graphene-coated single crystal cathode material include: at room temperature, the binder and the solvent B are mixed according to a mass ratio of 1:9 to form an organic solvent A; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com