Strong-flavor flavoring liquid as well as preparation method and application thereof

A strong-flavored and liquid-flavored technology, which is applied in the field of condiments, can solve problems such as unfavorable product label cleaning and health, poor implementability and economy, and complicated product ingredient list, so as to increase added value and have a strong and fresh taste. The effect of increasing the sweetness, aroma and texture of the mouthfeel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Prepare the taste liquid, the steps are as follows:

[0033] (1) Fully mix 40 parts by weight of soybean fermented liquid, 20 parts by weight of rice fermented liquid and 10 parts by weight of maltose syrup (the dry matter content of maltose is 40wt%) to obtain a mixture;

[0034] (2) by adding lactic acid, the pH value of the mixture is adjusted to 5.4 to obtain a thermal reaction preparation;

[0035] (3) React the thermal reaction preparatory material at 80° C. for 4 hours under normal pressure, and rapidly cool to normal temperature after the reaction to obtain a strong-flavor flavor liquid.

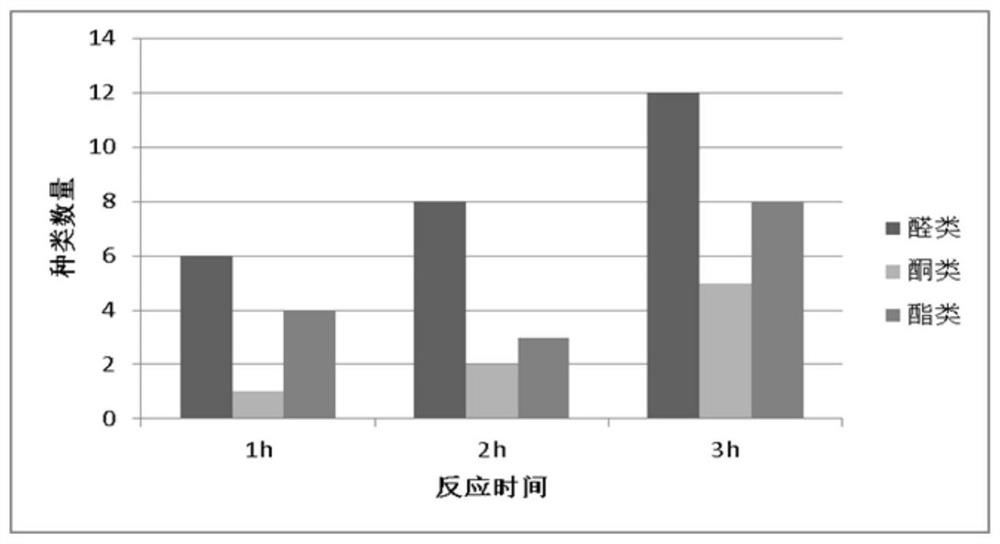

[0036] Compared with the mixture before the reaction, the taste liquid prepared in Example 1 has a mellow mouthfeel, and the richness of aroma is obviously enhanced. After detection, the kinds of volatile products (content ≥ 2wt%) such as aldehydes, ketones and esters in the taste liquid increased by 10 kinds compared with those before the reaction. The sensory evaluation...

Embodiment 2

[0040] 1. Prepare the taste liquid, the steps are as follows:

[0041] (1) 35 parts by weight of moromi, 30 parts by weight of distiller's grains and 9 parts by weight of fructose syrup (the dry matter content of fructose is 76wt%) are fully mixed to obtain a mixture;

[0042] (2) by adding acetic acid, the pH value of the mixture is adjusted to 5.0 to obtain a thermal reaction preparation;

[0043] (3) React the thermal reaction preparatory material at 95° C. for 3 hours under normal pressure, and cool down to normal temperature rapidly after the reaction to obtain a strong-flavored taste liquid.

[0044] Compared with the mixture before the reaction, the taste liquid prepared in Example 2 has a mellow mouthfeel, and the richness of aroma is obviously enhanced. After detection, the kinds of volatile products (content ≥ 2wt%) such as aldehydes, ketones and esters in the taste liquid increased by 15 kinds compared with those before the reaction. The results of sensory evaluatio...

Embodiment 3

[0050] 1. Prepare the taste liquid, the steps are as follows:

[0051] (1) In parts by weight, fully mix 45 parts of moromi, 30 parts of distiller's grains and 18.6 parts of fructose syrup (the dry matter content of fructose is 60wt%) to obtain a mixture;

[0052] (2) by adding acetic acid, the pH value of the mixture is adjusted to 5.6 to obtain a thermal reaction preparation;

[0053] (3) React the thermal reaction preparatory material at 105° C. for 2 hours under normal pressure, and cool it down to normal temperature after the reaction to obtain a strong-flavor flavor liquid.

[0054] Compared with the mixture before the reaction, the taste liquid prepared in Example 3 has a mellow mouthfeel, and the richness of aroma is obviously enhanced. After detection, the kinds of volatile products (content ≥ 2wt%) such as aldehydes, ketones and esters in the taste liquid increased by 12 kinds compared with those before the reaction. The results of sensory evaluation show that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com