Method for preparing sun-cured tobacco by using tobacco characteristic extract

A characteristic extract and air-cured tobacco technology, which is applied in the field of improving the quality of air-cured tobacco, can solve the problems of insufficient smoke aroma and aroma, weak strength, and heavy spicy taste, so as to improve the aroma, reduce irritation, and taste good Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

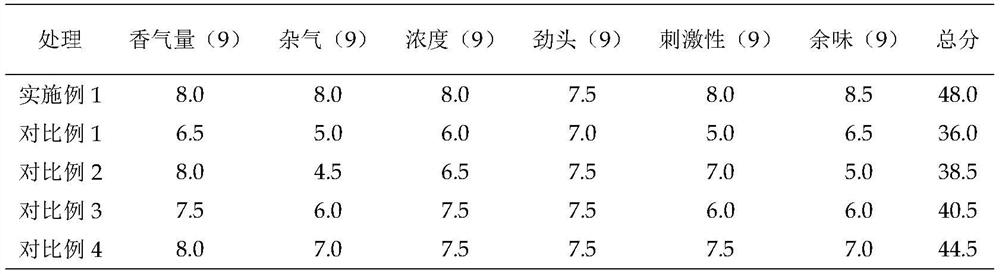

Examples

Embodiment 1

[0039] (1) After the fresh tobacco leaves are fully aired, turned yellow and fixed, and removed from the shelf, the water content of the tobacco leaves is 10wt%; put into water and soak for 30 minutes;

[0040] (2) The tobacco leaves of step (1) are evenly sprayed with the dry tobacco characteristic extract, and the fermentation time is 2 days at 90° C.; the moisture content of the tobacco leaves during fermentation is 30%;

[0041] (3) drying the tobacco leaves after fermentation for 10 days again, so that the moisture content of the tobacco leaves is 12wt%;

[0042] (4) Put the air-dried tobacco leaves into natural aging for 30 days, the air relative humidity is 50%, and the temperature is 30° C. at room temperature; the air-dried tobacco is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com