Casting water gap punching and shearing equipment

A technology of shearing equipment and castings, which is applied in the field of auxiliary processing equipment for wheel hub castings, can solve problems such as endangering the health of workers, damage to surrounding machinery and equipment, and high labor intensity of workers, so as to avoid a large amount of dust, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

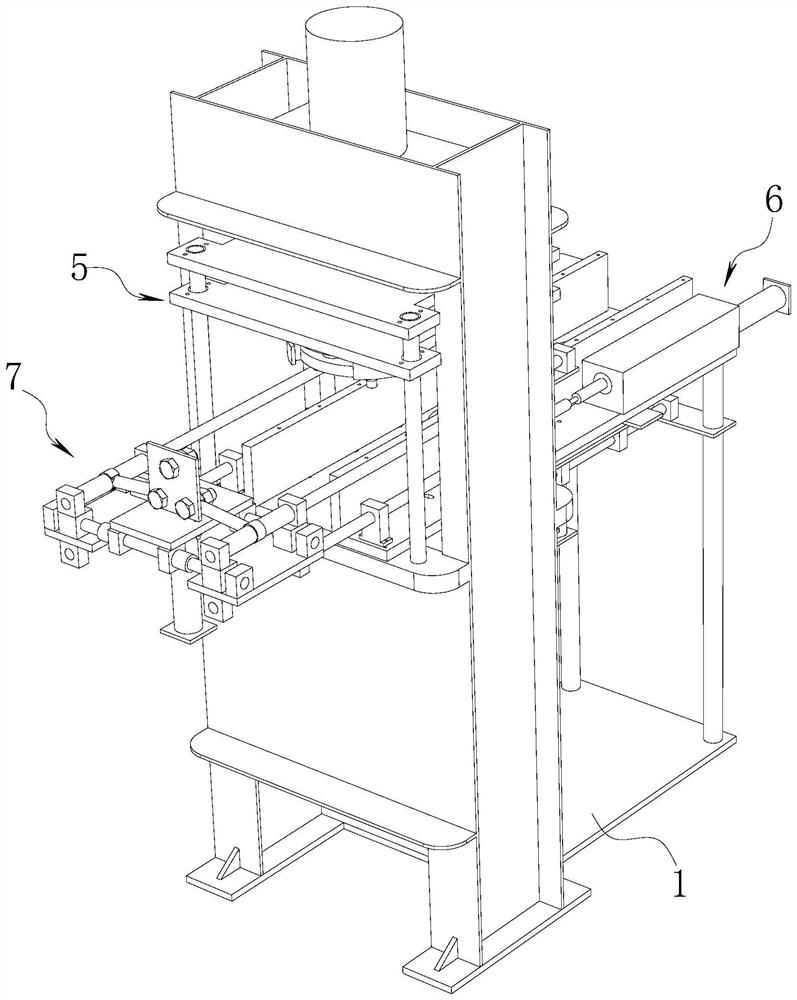

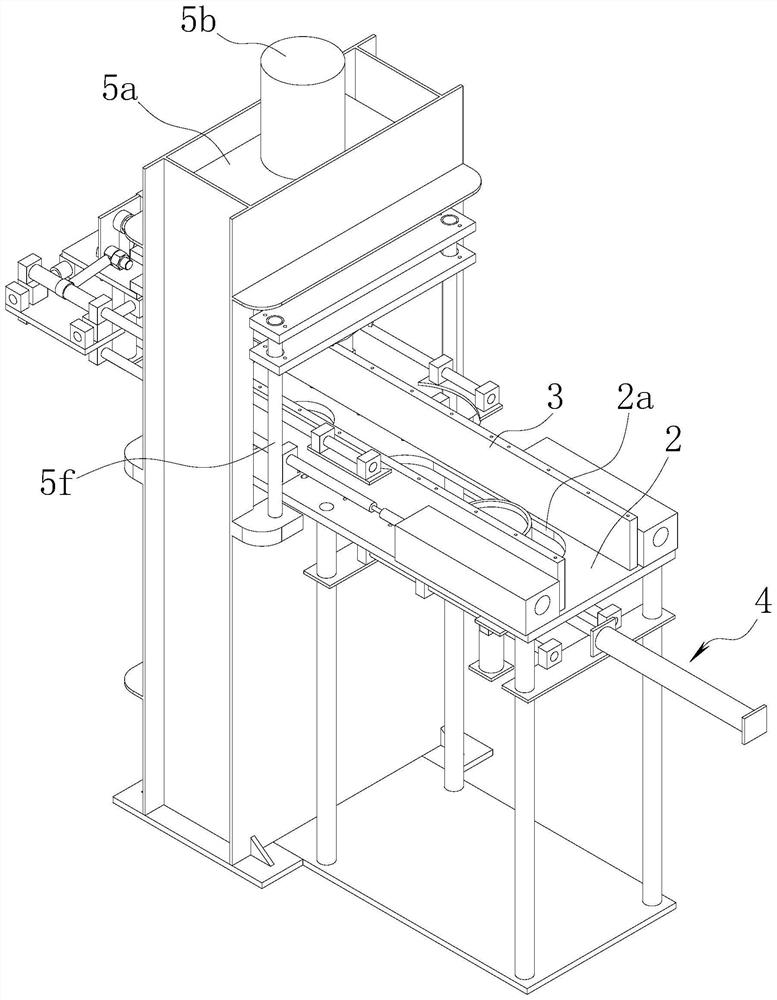

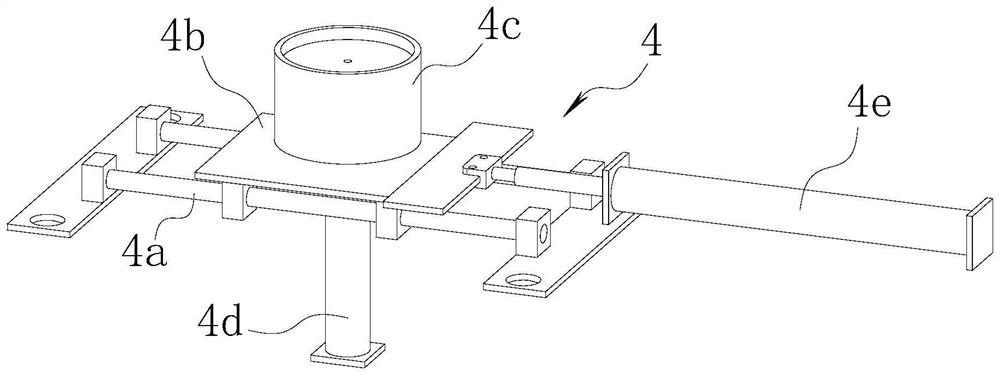

[0033] refer to figure 1 with figure 2 As shown, a casting nozzle punching and shearing equipment of the present invention includes a frame 1, a workbench 2 is horizontally arranged on the frame 1 along the length direction, and artificial devices are sequentially arranged on the workbench 2 along the length direction. Material station, automatic feeding station, punching and shearing station and discharging station, each station is arranged in a straight line and the punching and shearing station and discharging station are arranged next to each other. The frame 1 between the stations is provided with two parallel and spaced guide rails 3 for supporting the casting and for the sliding of the casting, and between the two guide rails 3 there is a manual loading station and an automatic feeding station. There is a casting lifting and conveying mechanism 4; a punching and shearing mechanism 5 is arranged on the frame 1 corresponding to the punching and shearing station.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com