Bearing steel and production method thereof, and bearing ring and production method thereof

A production method and technology of bearing rings, applied in the field of bearing rings and their production, bearing steel and its production, can solve the problems that cannot meet the requirements of level 1 stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

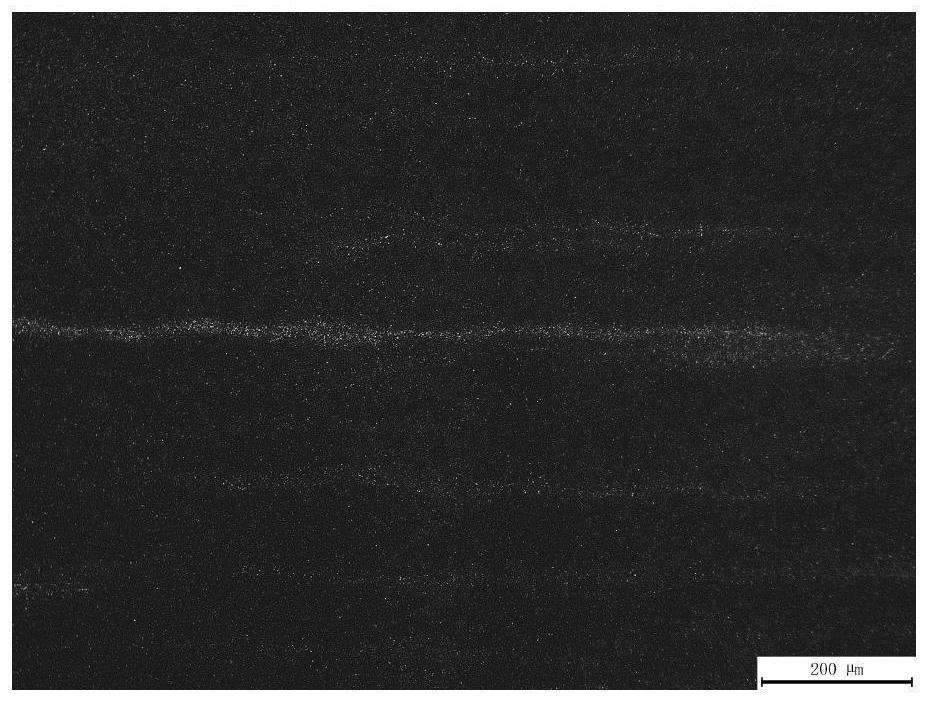

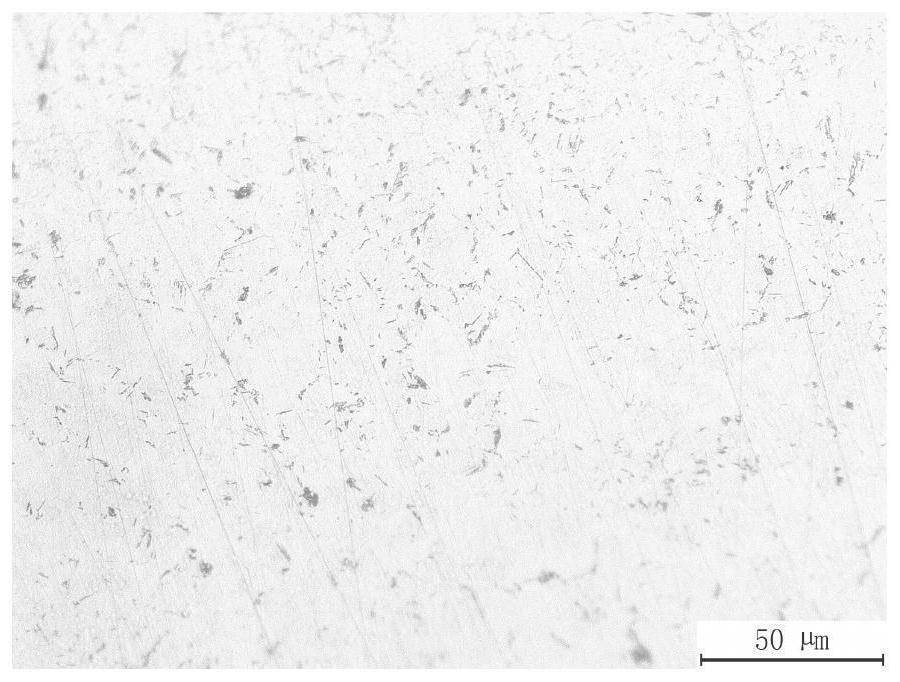

Image

Examples

Embodiment 1

[0085] 1. The production process of bearing steel is as follows:

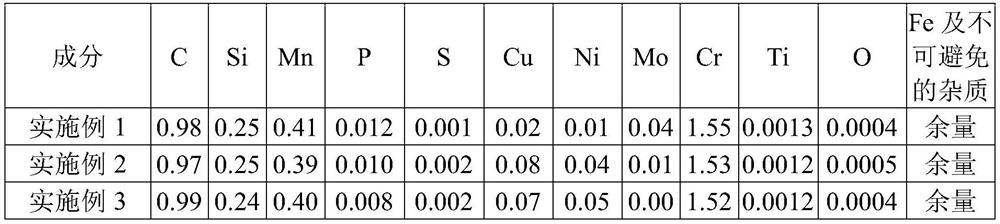

[0086] (1) Part of the raw materials are first smelted in the converter, and then other raw materials are added for LF refining outside the furnace. Wherein, the total composition of the raw materials added above satisfies the composition shown in Table 1.

[0087] (2) RH vacuum degassing.

[0088] (3) Billet continuous casting.

[0089] The whole process adopts closed protective pouring to avoid secondary oxidation of molten steel. The cross-sectional dimensions of the slab are shown in Table 2.

[0090] In the billet continuous casting, secondary cooling is performed on the casting slab with liquid core; and the conditions of the secondary cooling include: cooling in four stages from top to bottom, and the amount of water cooled in four stages from top to bottom They account for 40%, 30%, 20%, and 10% of the total cooling water respectively.

[0091] In the secondary cooling, the slab with the liquid cor...

Embodiment 2

[0105] According to the method of Example 1, the difference is that the process conditions of the soft reduction are different. Specifically, the first soft reduction is carried out at a distance of 19 meters from the upper mouth of the crystallizer along the length extension direction of the slab. , and control the solid phase rate to 0.65, the reduction rate to 0.6mm / m, and the reduction amount accounts for 16% of the total reduction amount; carry out the second light reduction at a distance of 24 meters from the upper mouth of the crystallizer, and control the solid phase The reduction rate is 0.84, the reduction rate is 2mm / m, and the reduction accounts for 55% of the total reduction; the third light reduction is carried out at a distance of 27 meters from the upper mouth of the crystallizer, and the solid phase rate is controlled to be 0.98, and the reduction The rate is 2.6mm / m, and the reduction accounts for 29% of the total reduction; and it is carried out according to ...

Embodiment 3

[0108] According to the method of Example 1, the difference is that the process conditions of the soft reduction are different. Specifically, the first soft reduction is carried out at a distance of 21 meters from the upper mouth of the crystallizer along the length extension direction of the slab. , and the solid phase rate is controlled to 0.6, the reduction rate is 1mm / m, and the reduction accounts for 24% of the total reduction amount; the second light reduction is carried out at a distance of 22 meters from the upper mouth of the crystallizer, and the solid phase rate is controlled is 0.72, the reduction rate is 2.5mm / m, and the reduction accounts for 45% of the total reduction; the third light reduction is carried out at a distance of 25 meters from the upper mouth of the crystallizer, and the solid phase ratio is controlled to be 0.85, and the reduction The rate is 3mm / m, and the reduction accounts for 31% of the total reduction; and it is carried out according to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com