Automatic piston mounting machine for piston type compressor

An automatic installation and compressor technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as time-consuming and laborious, and achieve the effect of great potential for functional expansion, easy connection, and prevention of mechanical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

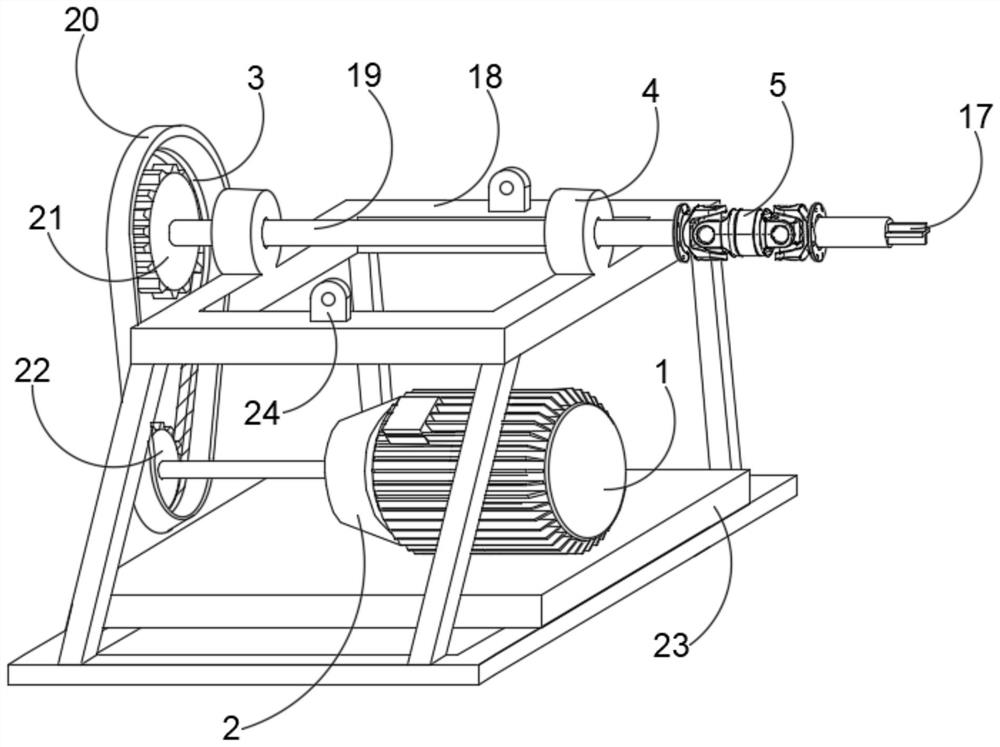

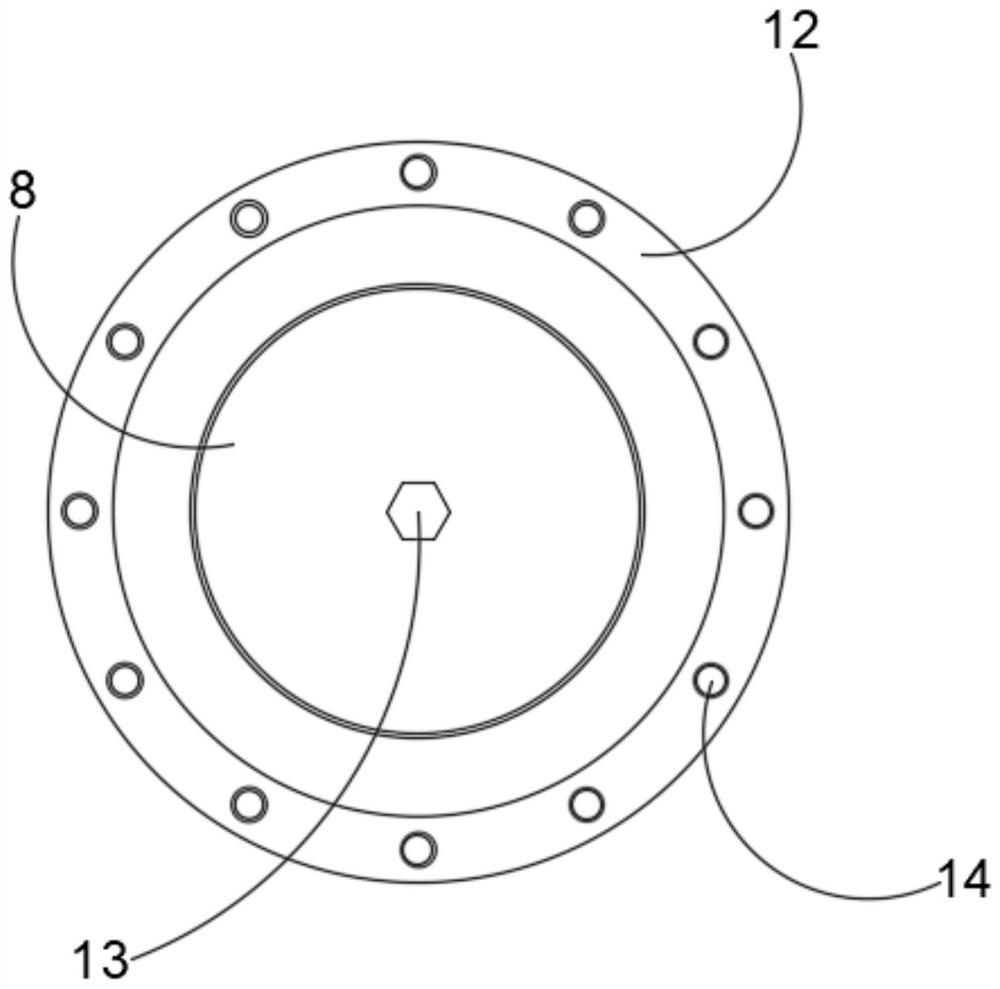

Embodiment 1

[0022] Embodiment one, by Figure 1-4 Given, the piston automatic piston compressor installation machine includes an assembly frame 18, a special extension sleeve 25 and a piston 8, and a motor 1 is installed on the assembly frame 18, and the motor 1 is connected with a driving sprocket 22 through a reducer 2. According to On-site maintenance efficiency and safety considerations, the transmission ratio of reducer 2 is 1:59 type cycloid reducer, the actual output speed is 25r / min, it only takes 3 minutes to connect the crosshead and piston rod in place, and the driving sprocket is 22 The driven sprocket 21 is connected through the transmission chain 3, and the driven sprocket 21 is fixedly connected with the transmission shaft 19. According to the on-site maintenance requirements of the propylene compressor, the motor with the explosion-proof mark ExdIIBT4Gb is selected, and the power of the motor 1 is determined according to the torque requirement. It is selected as 7.5kW, spr...

Embodiment 2

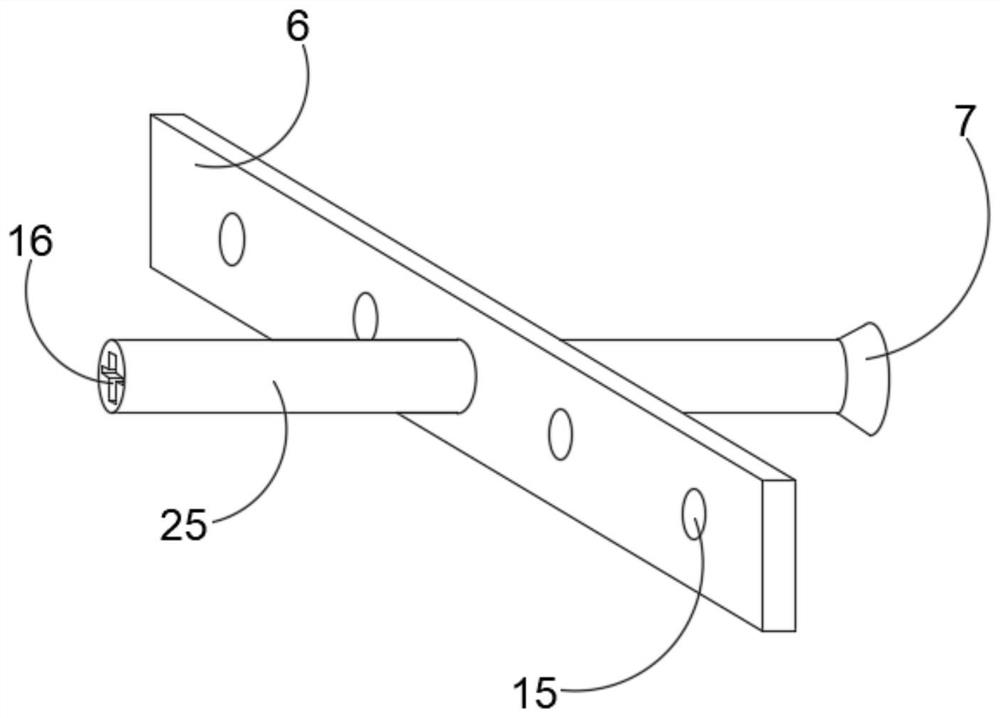

[0023] Embodiment 2, on the basis of Embodiment 1, the spline 17 is a cross-shaped structure, and the transmission joint groove 16 is a cross-shaped groove, the spline 17 can be in various shapes, and the cross-shaped spline 17 can be inserted into the transmission joint groove Drive lengthening special sleeve 25 to rotate and realize stable transmission in 16.

Embodiment 3

[0024] Embodiment 3, on the basis of Embodiment 1, a base 23 is fixedly welded on the assembly frame 18, the motor 1 is fixedly installed on the top of the base 23 through the motor base, and the motor 1 is mounted on the assembly frame 18 by using the base 23 The stable installation is conducive to ensuring the stability of the motor 1 when it is working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com