Grinder automatic production line and automatic production method

An automatic production line and grinding machine technology, applied in the direction of grinding machines, grinding feed movement, grinding machine tool parts, etc., can solve the problems of cumbersome operation, narrow versatility, and decreased feeding accuracy, so as to improve feeding accuracy and automation High degree of effect with less manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

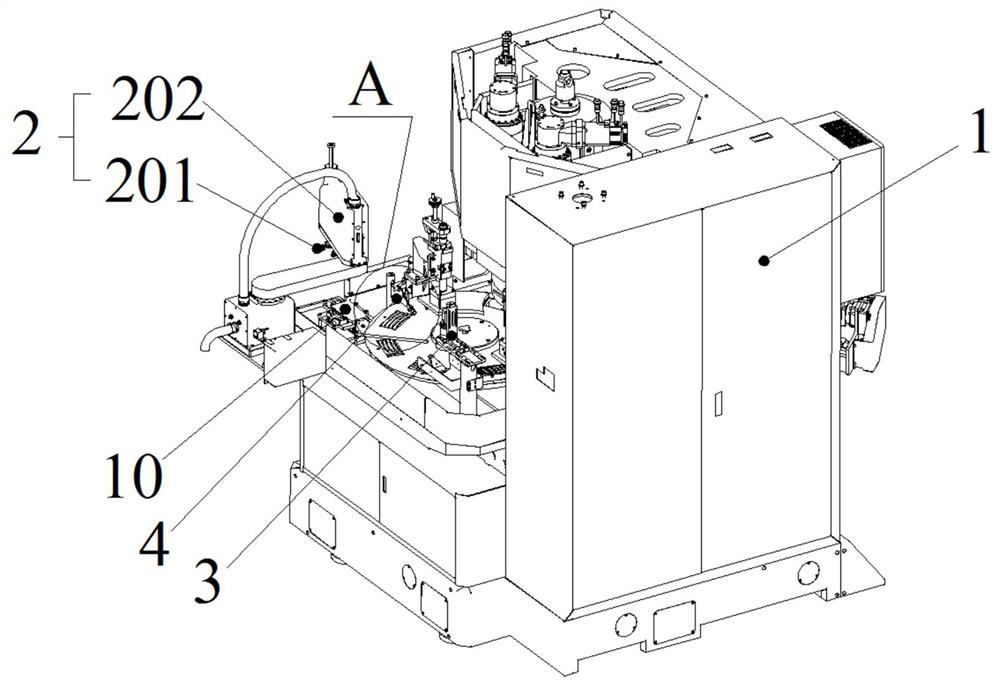

[0044] like figure 1 , Image 6 As shown, the automatic grinding machine production line for grinding hard and brittle materials in this embodiment includes a grinding machine and an incoming material conveying line 8, a blanking conveying line 9, a grabbing and unloading mechanism 2 arranged around the grinding machine The feeding position accuracy correction mechanism 10 for positioning the incoming material of the incoming material conveying line 8; the grinding machine includes a grinding machine body 1, and a rotatable feeding plate 101 is provided on the grinding machine body 1, and a feeding plate 101 is provided for accommodating hard and brittle materials. In the receiving chamber 102, the grasping and unloading mechanism 2 is interlocked with the feeding tray 101, so that the grasping and unloading mechanism 2 can rotate synchronously with the feeding tray 101 when feeding material to the receiving chamber 102.

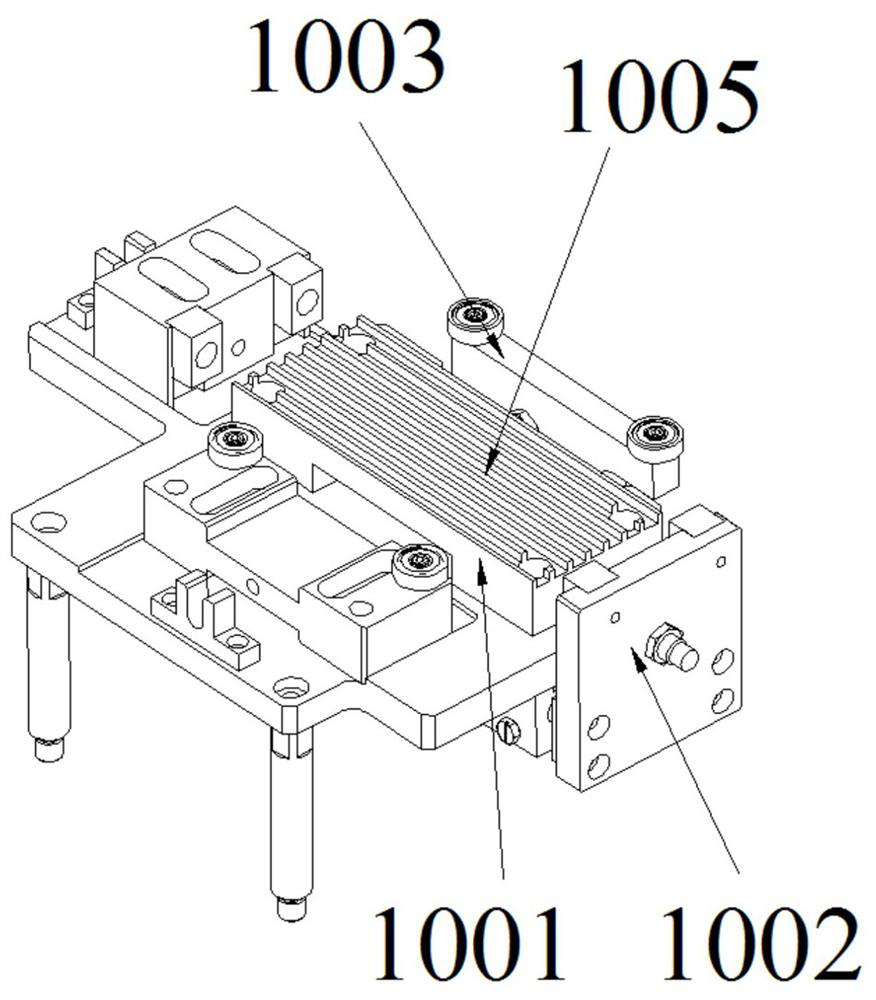

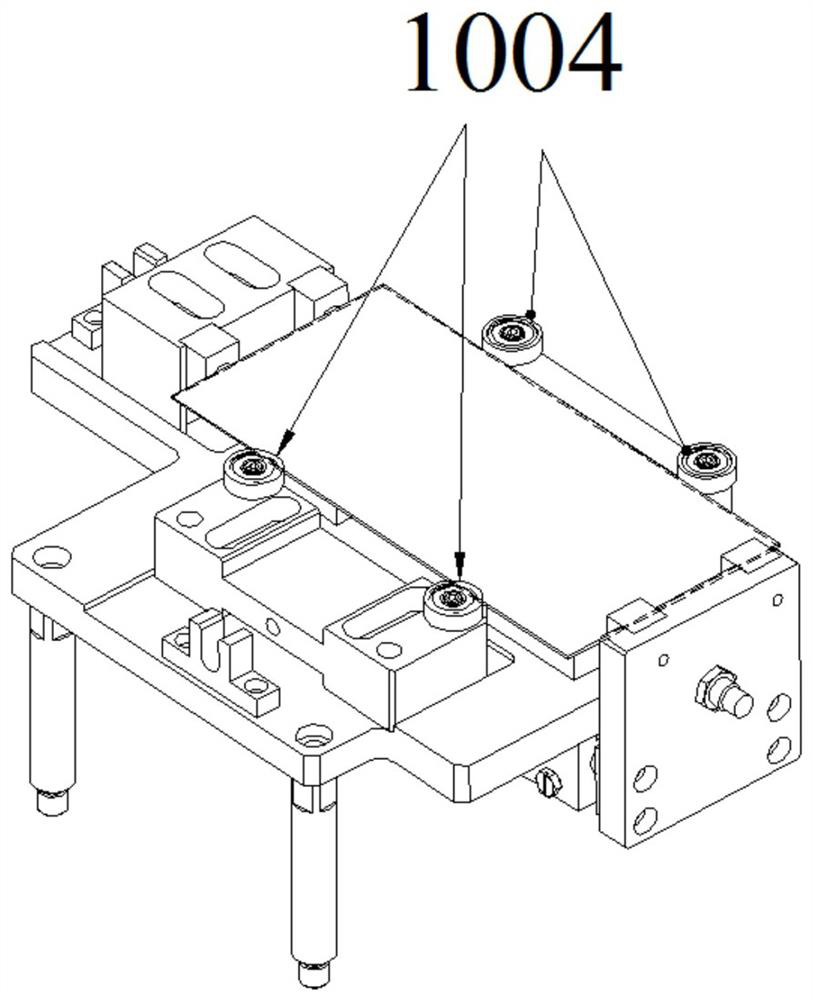

[0045] like figure 2 , 3 As shown, in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com