A method for preparing hollow sphere metal matrix lightweight composite material by powder injection molding

A technology of powder injection molding and composite materials, which is applied in metal processing equipment, transportation and packaging, etc. It can solve problems such as inability to mass produce, poor forming ability, and lower density, and achieve high production efficiency, low material density, and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

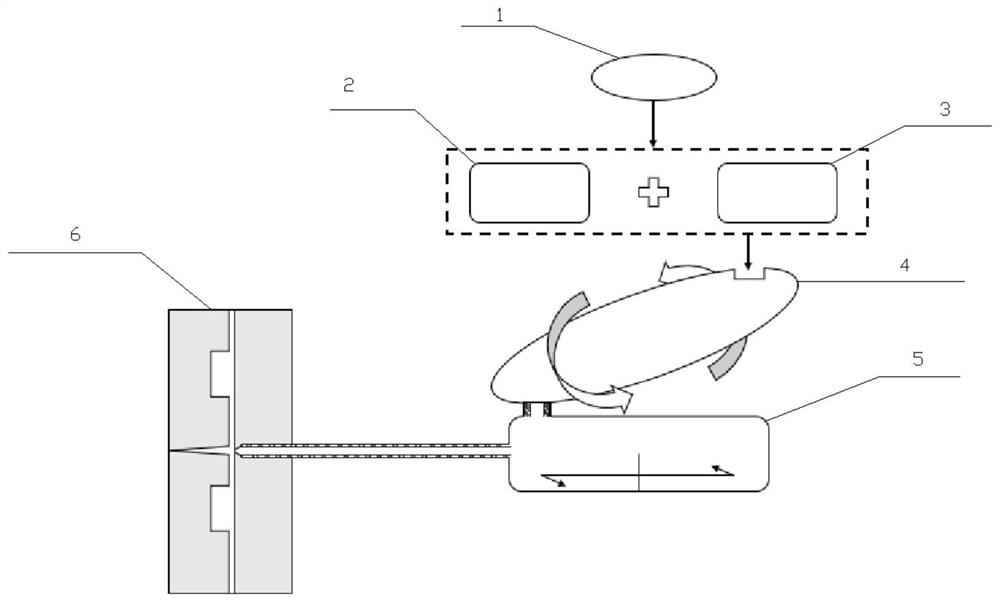

[0037] see figure 1 , The hollow spheres used in this embodiment are SiC hollow spheres with a particle size of 0.2 mm, and the metal matrix used is aluminum powder with a particle size of 20 μm.

[0038](1) Mix SiC hollow spheres and aluminum powder at a volume ratio of 3:2, then add 8% by weight of polyethylene glycol to obtain a premix, put the premix into a three-axis multifunctional hydraulic lift mixer at 80r Stir for 1 hour at a speed of 1 / min; then add the mixed premix into the mixer, knead at 200°C for 1 hour to make a uniform feed, and then put the feed into granulation to make feed injection granulation, the granulation temperature is 150°C;

[0039] (2) Preheat the feed granules at 200°C for 1 hour, put the preheated feed granules into the injection molding machine and perform rapid injection molding under the pressure of 80MPa and the injection speed of 60g / s, and demould after cooling Obtain a green body with a specific shape;

[0040] (3) First put the blank...

Embodiment 2

[0043] see figure 1 , the hollow spheres selected in this embodiment are Al 2 o 3 Hollow spheres are mixed hollow spheres with a volume ratio of 1:5, and the metal base used is iron powder with a particle size of 15 μm.

[0044] (1) Al 2 o 3 Mix hollow balls and iron powder at a volume ratio of 1:1, add 6% by weight polyethylene glycol binder to obtain a premix, put the premix into a three-axis multifunctional hydraulic lift mixer at 60r / min Stir at a high speed for 0.5h; then add the mixed premix into the mixer, knead at 500°C for 2 hours to make a uniform feed, and then put the feed into granulation to make feed injection pellets , the granulation temperature is 200°C;

[0045] (2) Preheat the feed granules at a temperature of 500°C for 1 hour, put the preheated feed granules into the injection molding machine, and perform rapid injection molding under a pressure of 100 MPa and an injection speed of 80 g / s, and demould after cooling Obtain a green body with a specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com