Method for recovering wool fibers by using compound enzyme preparation

A compound enzyme preparation and wool fiber technology, applied in the direction of plastic recycling, recycling technology, application, etc., can solve the problems of wool fiber recycling and utilization instructions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

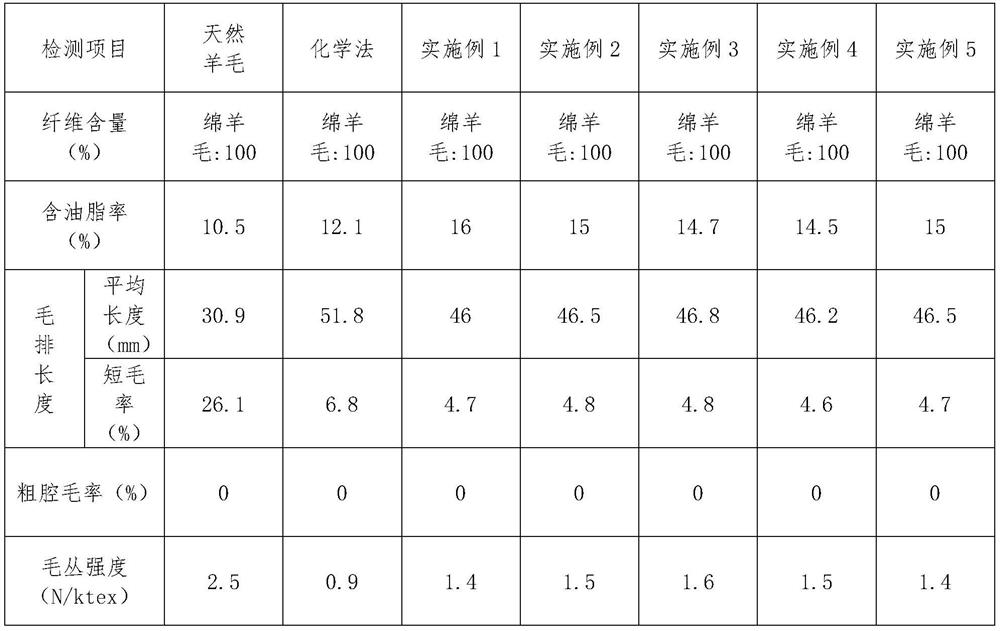

Examples

Embodiment 1

[0023] The method for utilizing composite enzyme preparation to reclaim wool fiber comprises the following process steps:

[0024] A. Raw material pretreatment: Soak sheepskin scraps containing wool solid waste in tap water and keep at room temperature for 18 hours;

[0025] B. Drum hair removal: Put the pretreated raw materials into the drum, add alkaline protease, alkaline lipase and Na 2 SO 3 Carry out enzymatic hair removal; the reaction conditions are: temperature 37°C, rotation speed 10 rpm, liquor ratio 1:12; stop the reaction after not less than 5 hours and collect wool fibers;

[0026] The mass ratio of alkaline protease to the liquid in the drum=4‰, the mass ratio of alkaline lipase to the liquid in the drum=4‰, Na 2 SO 3 The mass ratio to the liquid in the drum = 4‰.

[0027] The pH of the enzymatic hair removal reaction in the step B=9.

[0028] The enzyme activity of alkaline protease is 190,000 to 210,000 U / g, the reaction temperature of alkaline protease is...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is:

[0031] The method for utilizing composite enzyme preparation to reclaim wool fiber comprises the following process steps:

[0032] A. Raw material pretreatment: Soak sheepskin scraps containing wool solid waste in tap water and keep at room temperature for 12 hours;

[0033] B. Drum hair removal: Put the pretreated raw materials into the drum, add alkaline protease, alkaline lipase and Na 2 SO 3 Carry out enzymatic hair removal; the reaction conditions are: temperature 34°C, rotation speed 5 rpm, liquor ratio 1:8; reaction is stopped after not less than 5 hours and wool fibers are collected;

[0034] The mass ratio of alkaline protease to the liquid in the drum=1‰, the mass ratio of alkaline lipase to the liquid in the drum=1‰, Na 2 SO 3 The mass ratio to the liquid in the drum = 2‰.

[0035] The pH of the enzymatic hair removal reaction in step B is 7.

[0036] All the other contents are the same as in...

Embodiment 3

[0038] The difference between this embodiment and embodiment 1 is:

[0039] The method for utilizing composite enzyme preparation to reclaim wool fiber comprises the following process steps:

[0040] A. Raw material pretreatment: Soak sheepskin scraps containing wool solid waste in tap water and keep at room temperature for 15 hours;

[0041] B. Drum hair removal: Put the pretreated raw materials into the drum, add alkaline protease, alkaline lipase and Na 2 SO 3 Carry out enzymatic hair removal; the reaction conditions are: temperature 35°C, rotation speed 8 rpm, liquor ratio 1:10; stop the reaction after not less than 5 hours and collect wool fibers;

[0042] The mass ratio of alkaline protease to the liquid in the drum=2.5‰, the mass ratio of alkaline lipase to the liquid in the drum=2.5‰, Na 2 SO 3 The mass ratio to the liquid in the drum = 3‰.

[0043] The pH of the enzymatic hair removal reaction in the step B is 8.

[0044] All the other contents are the same as i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap