Ethylene-acrylate rubber resistant to 200 DEG C, low in pressure change and high in pulse

An acrylate, high-pulse technology, applied in the field of rubber materials, can solve the problems of high frequency and high pulse pressure, and achieve the effects of good heat resistance, improved strength and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

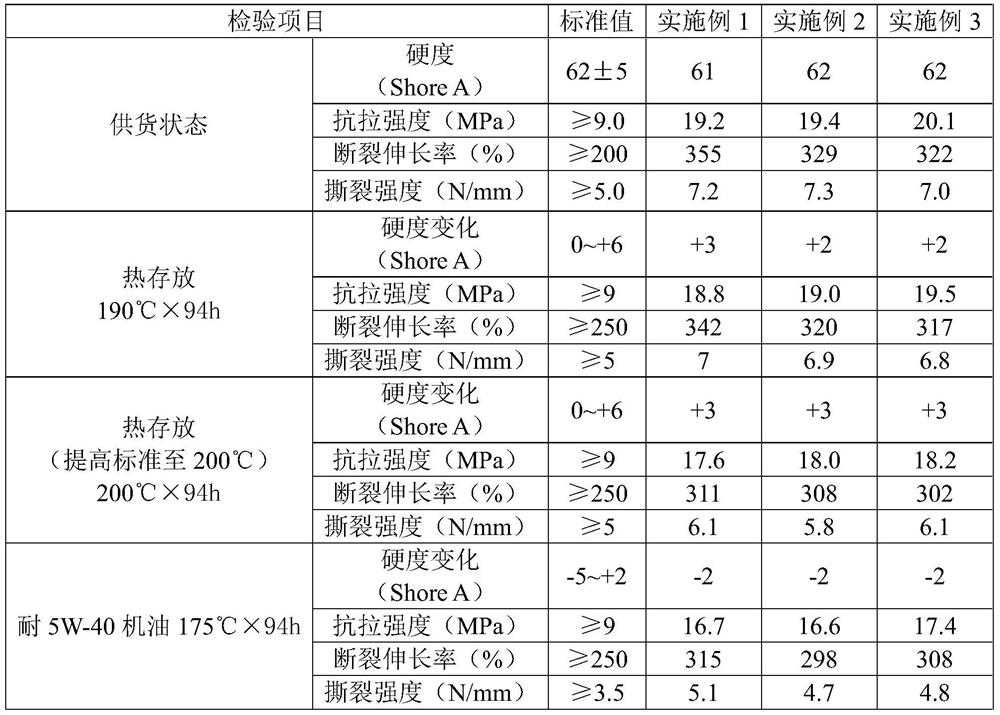

Embodiment 1

[0030] An ethylene-acrylate rubber with resistance to 200°C, low pressure change, and high pulse, including raw material components counted in parts by weight: 60 parts by weight of ethylene-acrylate rubber HT-OR, 40 parts by weight of ethylene-acrylate rubber 5394 Parts by weight, stearic acid is 1 part by weight, liquid antioxidant Naugard PS30 is 2 parts by weight, auxiliary agent 18D is 0.5 part by weight, auxiliary agent VAM is 1 part by weight, carbon black N550 is 50 parts by weight, modified ceramic micropowder 6000AS6 is 20 parts by weight, peroxide ointment BYG-1210 is 10 parts by weight, crosslinking agent ACT55 is 1.2 parts by weight, and crosslinking agent Diak No.1 is 2 parts by weight.

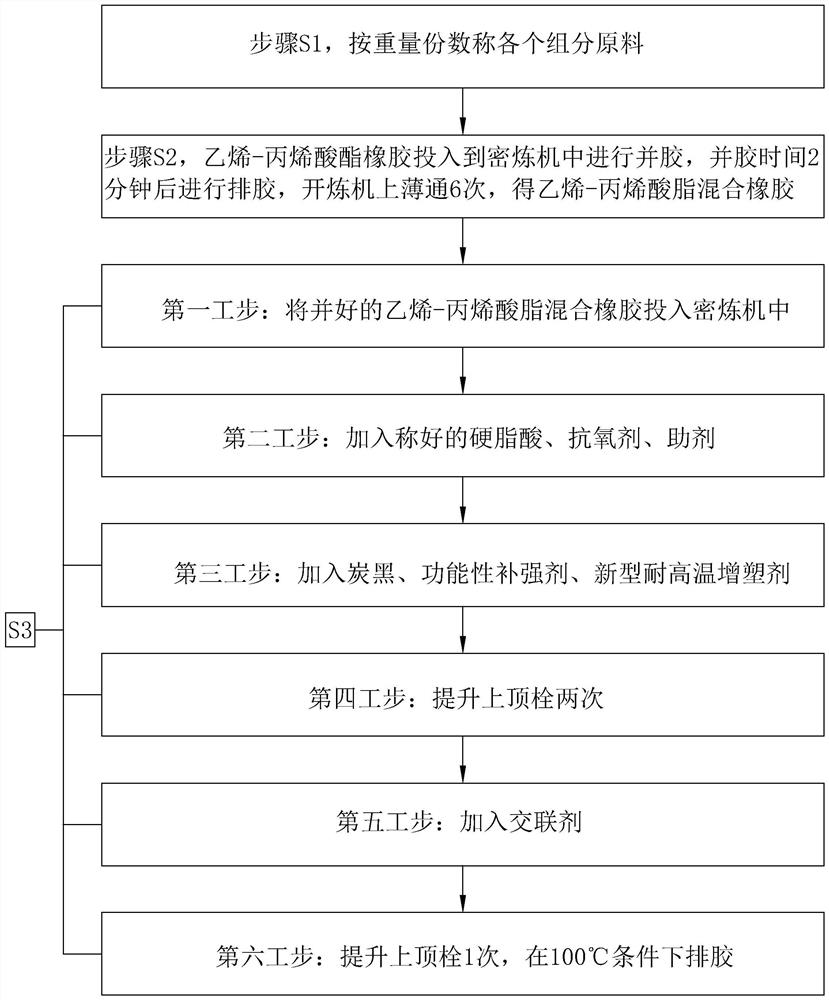

[0031] A preparation method of ethylene-acrylate rubber resistant to 200°C, low pressure change, and high pulse, such as figure 1 shown, including the following steps:

[0032] Step S1: weighing materials, weighing each component raw material by parts by weight.

[0033] Step ...

Embodiment 2

[0042] The difference from Example 1 is that it includes raw material components counted in parts by weight: 60 parts by weight of ethylene-acrylate rubber HT-OR, 40 parts by weight of ethylene-acrylate rubber 5394, and 1 part by weight of stearic acid , liquid antioxidant Naugard PS30 is 2.5 parts by weight, auxiliary agent 18D is 0.5 parts by weight, auxiliary agent VAM is 1 part by weight, carbon black N550 is 50 parts by weight, modified ceramic micropowder 6000AS6 is 25 parts by weight, peroxide oil The paste BYG-1210 is 15 parts by weight, the crosslinking agent ACT55 is 1.2 parts by weight, and the crosslinking agent Diak No.1 is 2 parts by weight.

Embodiment 3

[0044] The difference from Example 1 is that it includes raw material components counted in parts by weight: 60 parts by weight of ethylene-acrylate rubber HT-OR, 40 parts by weight of ethylene-acrylate rubber 5394, and 1 part by weight of stearic acid , 2.5 parts by weight of liquid antioxidant Naugard PS30, 0.5 parts by weight of auxiliary agent 18D, 1 part by weight of auxiliary agent VAM, 50 parts by weight of carbon black N550, 30 parts by weight of modified ceramic micropowder 6000AS6, peroxide oil The paste BYG-1210 is 20 parts by weight, the crosslinking agent ACT55 is 1.2 parts by weight, and the crosslinking agent Diak No.1 is 2 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com