Three-dimensional dry non-woven fabric composite material as well as preparation method and application thereof

A technology of composite materials and non-woven fabrics, which is applied in the direction of textiles and papermaking, non-woven fabrics, and layered products. It can solve the problems of wet non-woven fabrics, achieve stable dryness, speed up absorption, and reduce the risk of leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present application also provides a method for preparing the above-mentioned three-dimensional dry non-woven composite material, comprising the following steps:

[0061] Step 1: stacking the water-repellent non-woven fabric and the hydrophilic non-woven fabric to form a composite material layer.

[0062] In one embodiment, the composite material layer is formed by superimposing the water-repellent non-woven fabric and the hydrophilic non-woven fabric, which may be: the composite material is made by combining the water-repellent non-woven fabric and the hydrophilic non-woven fabric layer.

[0063] Preferably, the compounding process includes any one of glue compounding, spunlace compounding, needle-punched compounding, ultrasonic and thermal compounding. Using the compounding process for stacking can prevent the gap between the water-repellent non-woven fabric and the hydrophilic non-woven fabric. Interlayer, improve product reliability.

[0064] Preferably, the co...

Embodiment 1

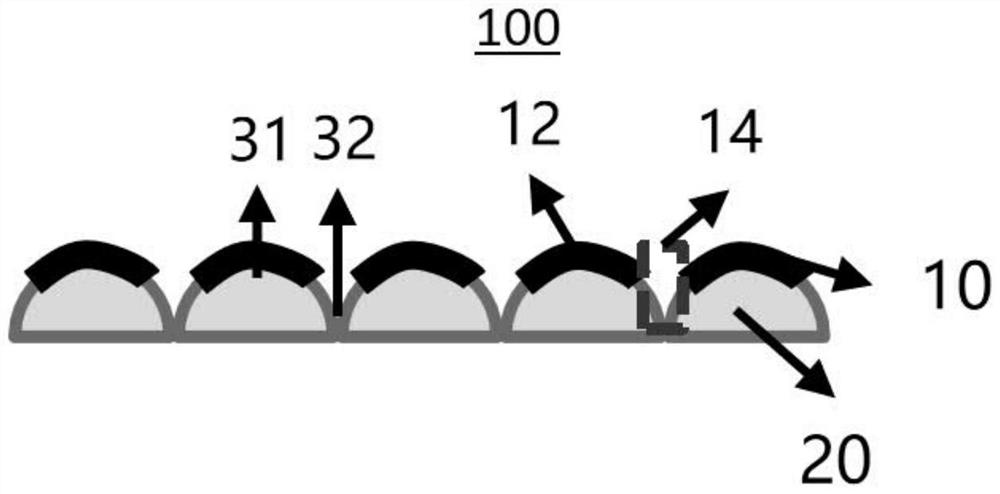

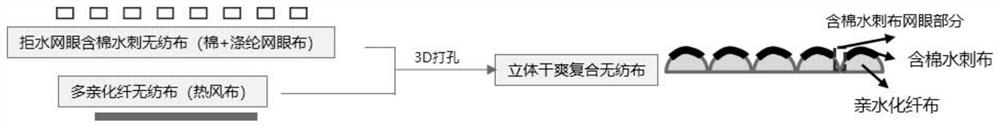

[0074] The water-repellent non-woven fabric of the surface layer 10 is made of water-repellent cotton spunlace non-woven fabric of about 25g / ㎡, the fiber fineness is 0.8-4.0dtex, the fiber length is 15-45mm, the mesh size is 4-50 mesh, the bottom layer 20 Hydrophilic non-woven fabric adopts 12-40g / m 2 Multi-hydrophilic type hot air cloth, the production process of the three-dimensional dry pure cotton spunlace nonwoven composite material of embodiment 1 is as follows Figure 4 As shown, it specifically includes the following steps:

[0075] 1) Raw material preparation: prepare water-repellent raw cotton, that is, 100% pure natural cotton fiber without degreasing, for use.

[0076] 2) Cleaning: Use the cleaning machine to remove impurities from the raw cotton, and screen out the three threads and foreign objects in the raw cotton.

[0077] 3) Carding: It includes two parts: opening and carding, that is, opening the cotton fiber into a single fiber state, which is convenient f...

Embodiment 2

[0089] The surface layer water-repellent non-woven fabric adopts water-repellent cotton-containing spunlace non-woven fabric, and the composition of water-repellent cotton-containing spunlace non-woven fabric is a combination of 50% cotton + 50% polyester. Softness, at the same time taking into account the hot-melt properties of the water-repellent non-woven surface layer, which is convenient for hot-melt bonding with other hot-melt materials. The bottom hydrophilic non-woven fabric adopts 12-40g / m 2 Many hydrophilic type hot-air cloths, the production process of the three-dimensional dry and dry cotton-containing non-woven composite material of embodiment 2 is as follows image 3 As shown, it specifically includes the following steps:

[0090] 1) Material preparation: fully mix 50% raw cotton and 50% polyester fiber and prepare for use.

[0091] 2) Cleaning: Use the cleaning machine to remove impurities from raw cotton and polyester, and screen out three threads and foreign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com