High-universality vehicle-mounted screw air compressor head assembly

A versatile, vehicle-mounted technology that can be used in machines/engines, rotary-piston machines, components of pumping devices for elastic fluids, etc. problems, to avoid transmission instability problems, reduce downtime, and reduce overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

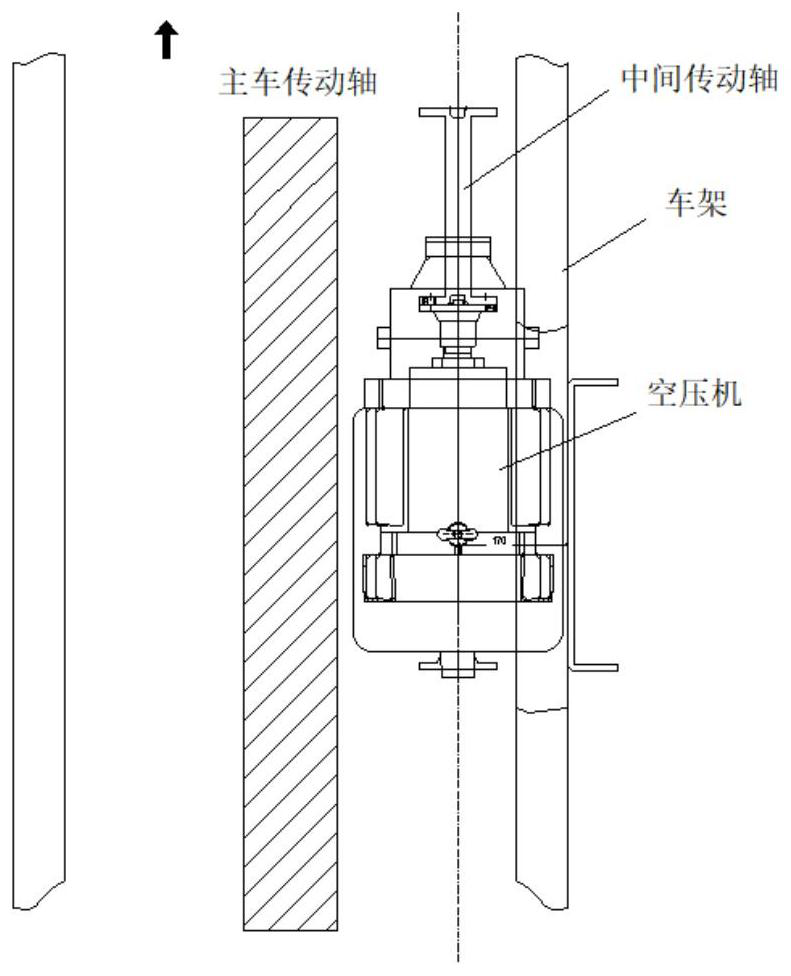

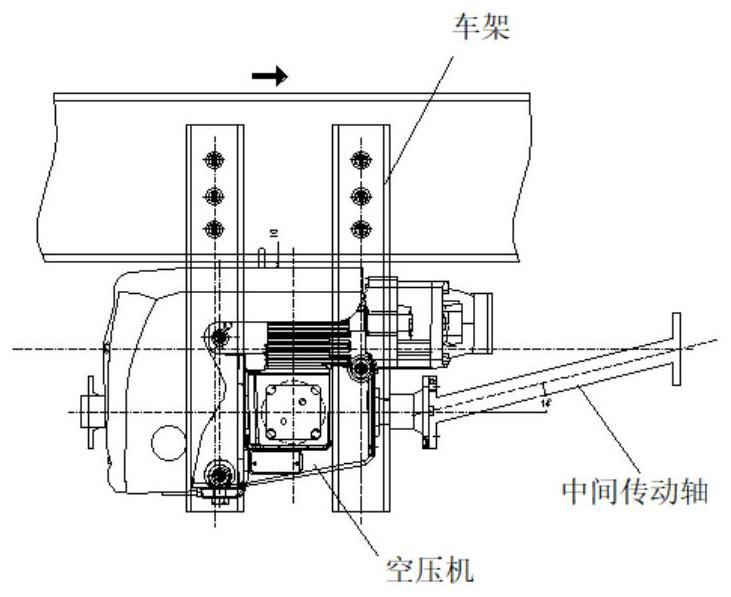

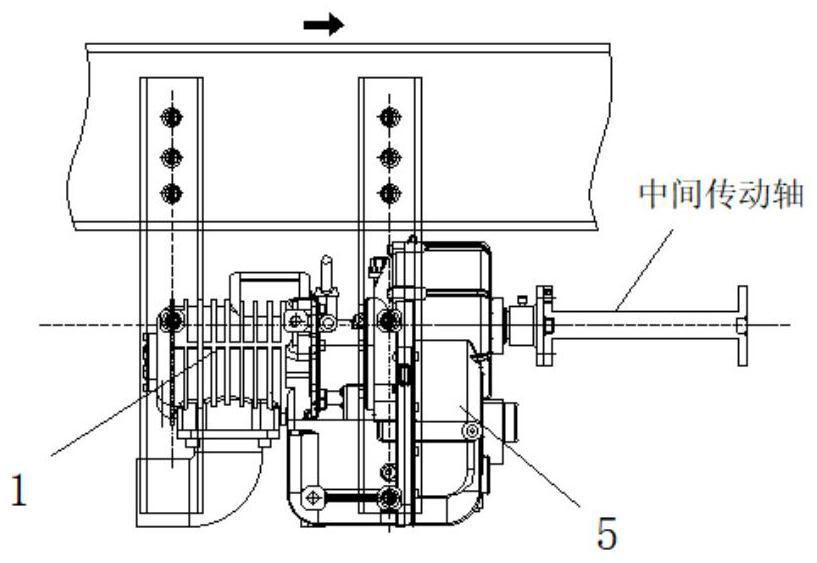

[0037] Refer Figure 1-10 As shown, the present embodiment is a high versatile vehicle-loaded screw air compressor head assembly, including the head casing 1, which is provided in the chassis 11 and the male screw 12 in the head housing 1, detachable. The transition box body 2 at the front end of the head housing 1 is provided in the transition box 2, and the first bearing group 21 and the first sealing group 22 are provided in the front section of the female screw 11 and the male screw 12, and is disposed at the tail housing 1. The end sleeve is set in the second bearing group 23 and the second sealing group 24 in the rear section of the female screw 11 and the male screw 12, which is provided in the transition box body 2 to the synchronous active gear 13 on the female screw 11, which is located in the transition box. The body 2 is arranged on the male screw 12 and the synchronous passive gear 14 engaged with the synchronous active gear 13, and is arranged on the female screw 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com