Capillary tube-based optical fiber SPR sensor with temperature compensation

A technology of temperature compensation and capillary, which is applied in the direction of instruments, scientific instruments, and material analysis through optical means. It can solve the problems of no temperature compensation, the influence of measurement results, and processing difficulties, and achieve low cost and solve structural instability. The effect of high stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose and advantages of the present invention clearer, the specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto. protection scope of the invention.

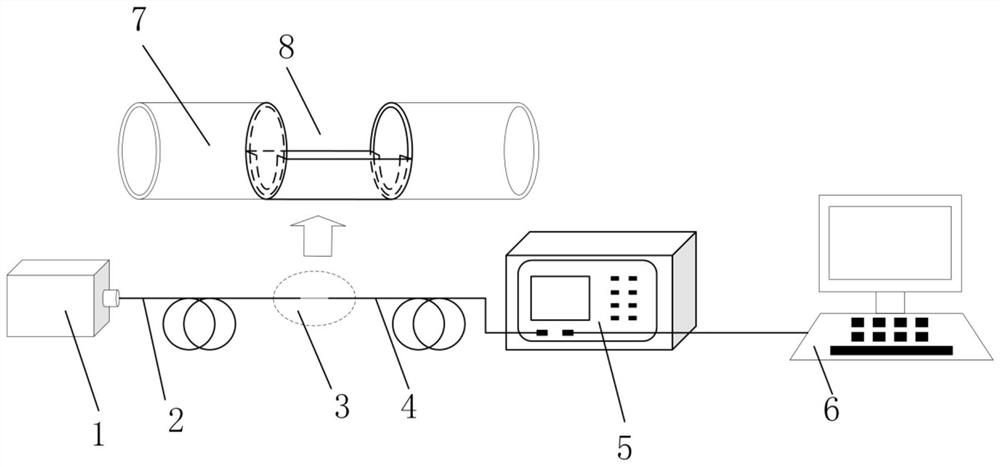

[0024] see figure 1 , the present invention uses a capillary to propose a fiber optic SPR sensor with temperature compensation, including a light source 1, a light injection fiber 2, a sensing area 3, a light collection fiber 4, a spectrometer 5, and a computer 6. Since the fabricated fiber probe has a symmetrical structure, the light source can be connected to any end of the fiber probe through an optical fiber, and the other end of the fiber probe is connected to a spectrometer. When working, the light emitted by the light source 1 reaches the capillary optical fiber sensing probe 3 of the side throwing structure through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com