Nuclear waste sealing container preparation system

A preparation system and nuclear waste technology, applied in the field of nuclear waste storage container preparation system, can solve the problems that the manufacturing process cannot meet the minimization of radioactive waste, and achieve the effect of minimization of radioactive waste, short circulation path and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

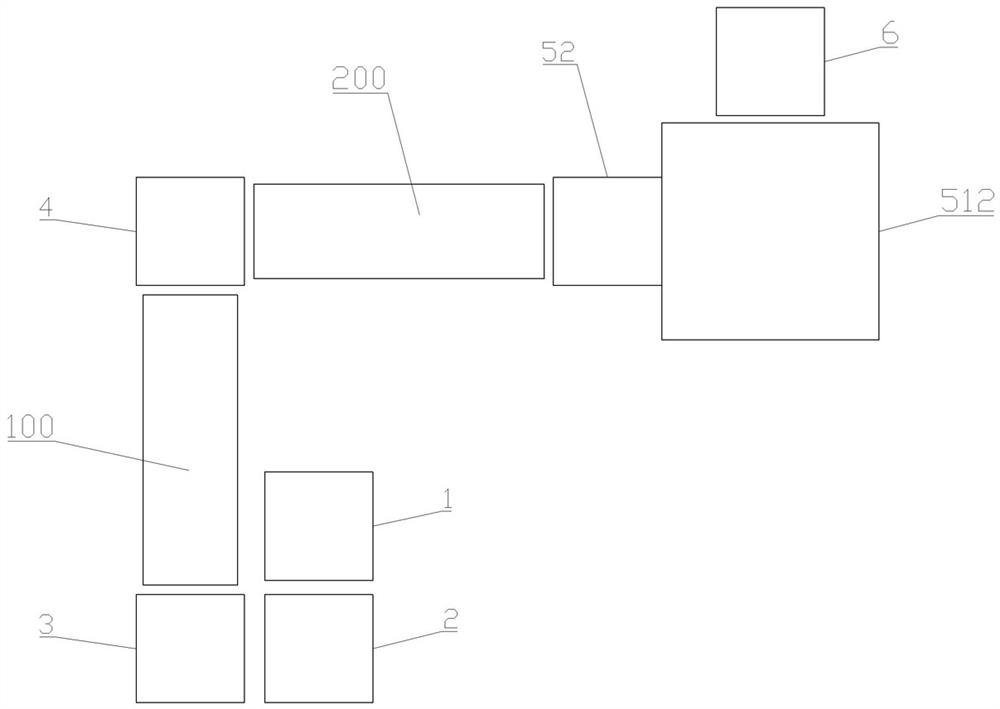

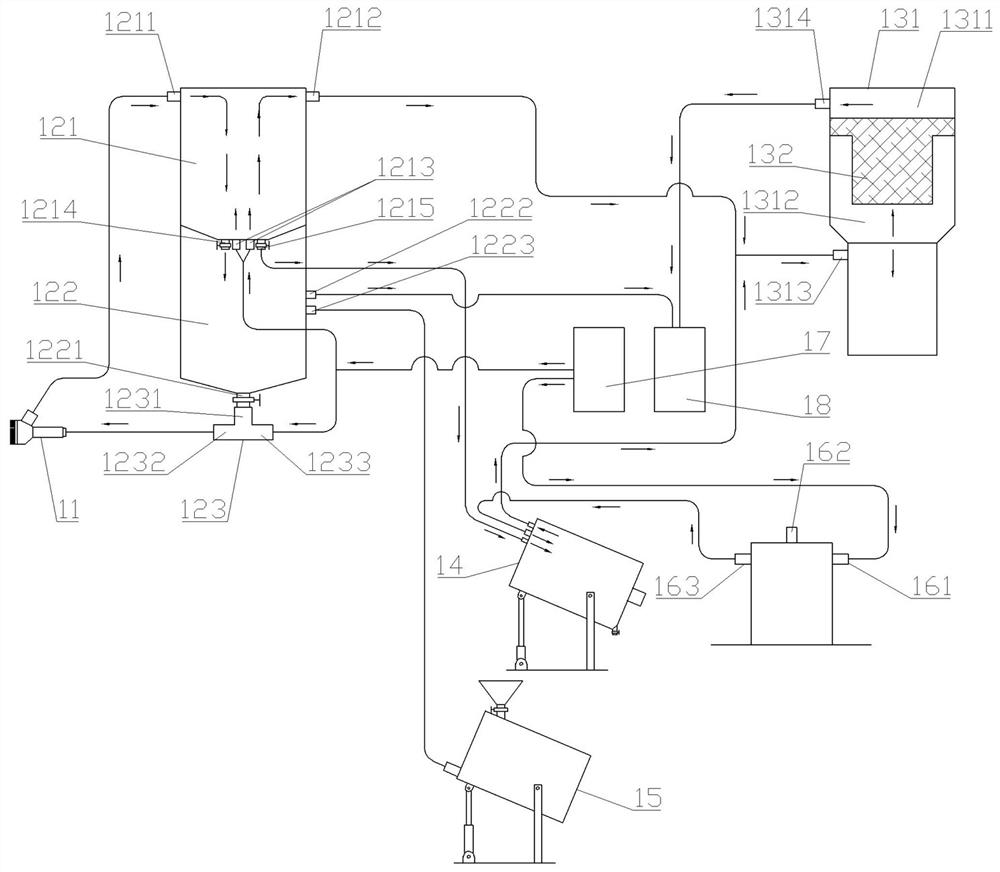

[0082] Such as Figure 1-12 As shown, the nuclear waste storage container preparation system is used for the preparation of nuclear waste storage containers, which includes a shot blasting decontamination device 1, a metal cutter 2, a metal shredder 3, a metal compression baler 4, a metal smelting and feeding assembly Forming and sealing container preparation assembly.

[0083] Shot blasting decontamination device 1, metal cutting machine 2, metal shredder 3, metal compression packing machine 4, metal smelting and feeding assembly, and sealing container preparation assembly are used in sequence in the preparation process of nuclear waste sealing containers.

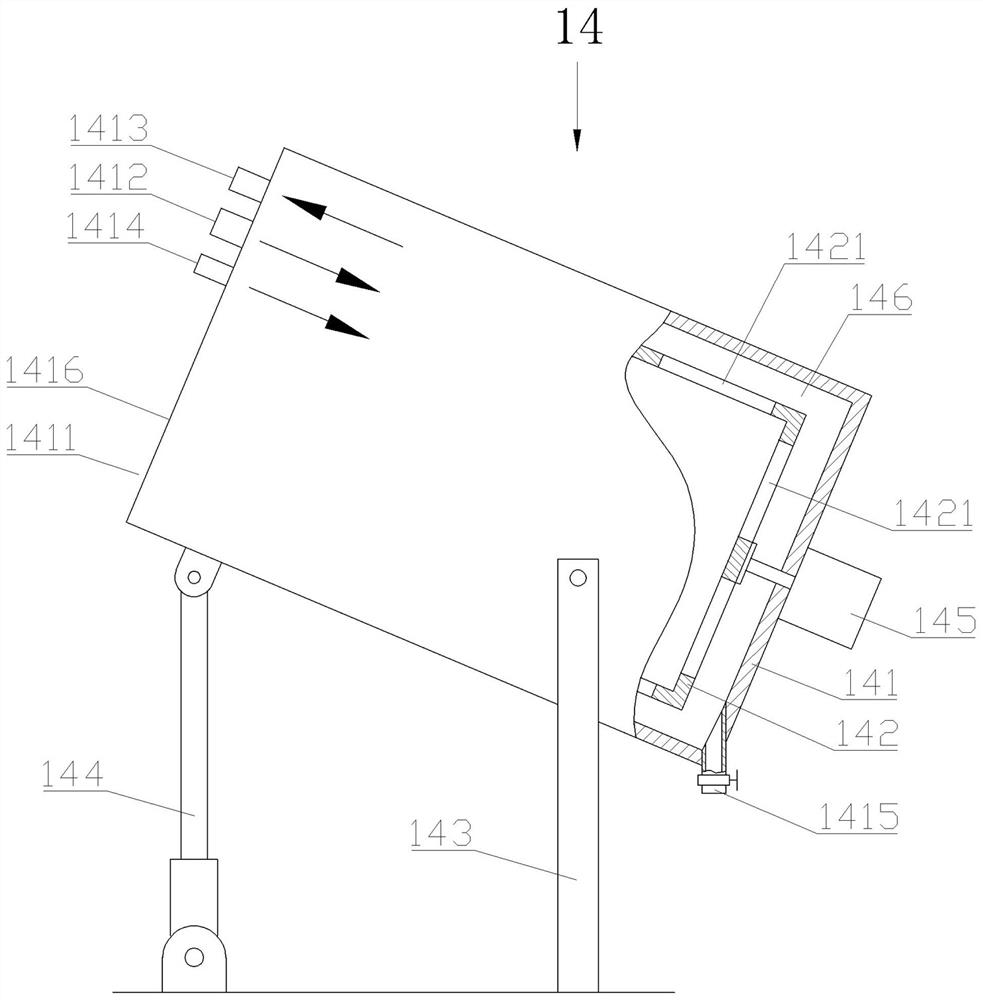

[0084] The shot blasting decontamination device 1 includes a spray gun 11, a dust separator, a dust collector, a steel ball cleaner 14, a steel ball repatriator 15, a dry ice supply device, a high-pressure air source 17 and a negative pressure suction device 18.

[0085] The inside of the spray gun 11 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com