Solid-state relay of contactless switch

A solid state relay, non-contact switch technology, applied in electronic switches, circuits, electrical components, etc., can solve the problems of mechanical fatigue life, low output signal sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

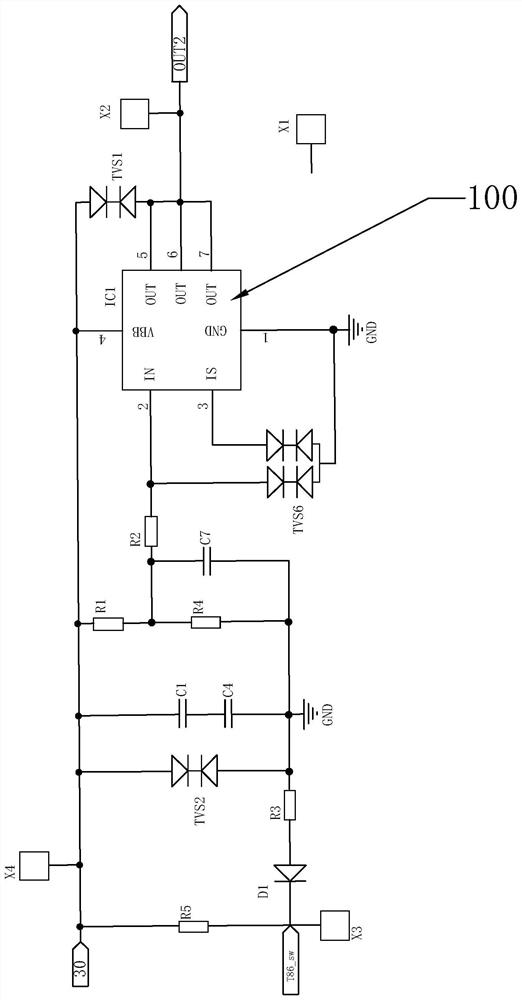

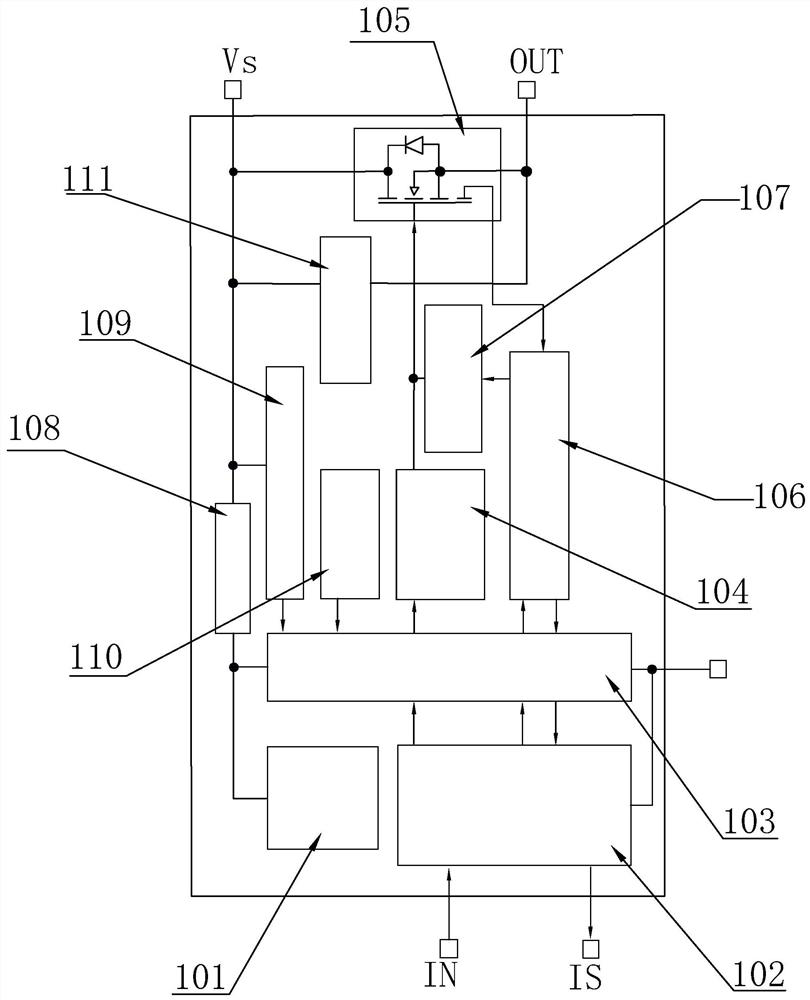

[0011] The disclosure of the present invention relates to a solid-state relay of a non-contact switch. In the implementation case of the present invention, it includes two input terminals and one output terminal, and also includes a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, and a capacitor C1 , capacitor C4, capacitor C7, diode D1, transient diode TVS1, transient diode TVS2, transient diode TVS6 and MOS control unit 100, capacitor C1 and capacitor C4 are connected in series to form a capacitor group, resistor R5, transient diode TVS2 and The capacitor groups are arranged in parallel in turn, the cathode of the diode D1 is electrically connected to R5, the anode of the diode D1 is electrically connected to one end of the resistor R3, the other end of the resistor R3 is electrically connected to the transient diode TVS2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com