Method for removing mutton smell from goat milk

A technology for removing mutton and goat milk, applied in dairy products, applications, milk preparations, etc., can solve the problems of goat milk color, texture, taste, cumbersome process, and not suitable for industrialized mass production, etc., to reduce goat milk smell Odor, elimination of muttony substances, effect of reducing muttony smell of goat milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A method for removing goat milk

[0081] (1) Pasteurization: sterilize fresh goat milk at 65°C for 30 minutes;

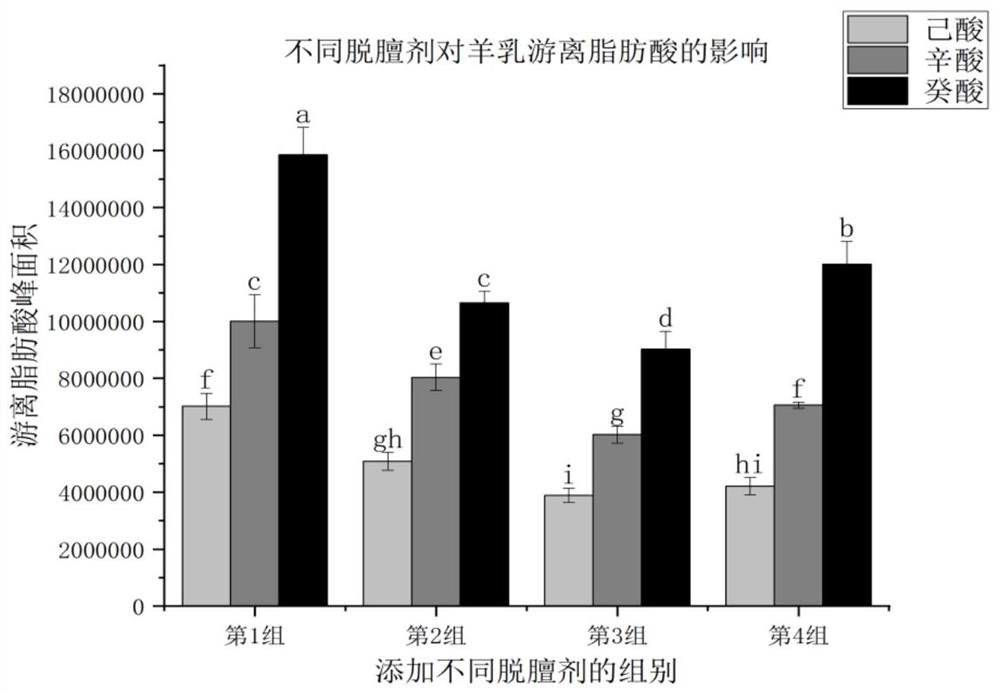

[0082](2) Detoxification: Divide the sterilized goat milk in step (1) into 5 parts, numbered 1~5, and add 50°C extruded whey protein isolate and 75°C extruded whey protein isolate to No.2~5 respectively. , 100°C extruded puffed whey protein isolate and 125°C extruded puffed whey protein isolate, the mass-volume percentages of the four kinds of extruded puffed whey protein isolates to goat milk are all 0.5%, and then respectively heated at 35°C Shake and stir for 30 minutes to obtain 4 different kinds of goat milk;

[0083] (3) Homogenize the goat milk prepared in step (2) under a pressure of 20 MPa to obtain demutated goat milk.

[0084] (4) No. 1 goat milk without puffed whey protein isolate was used as the control group for sensory evaluation, the results are shown in Table 2, and the comprehensive evaluation results after fuzzy mathematics processing are...

Embodiment 2

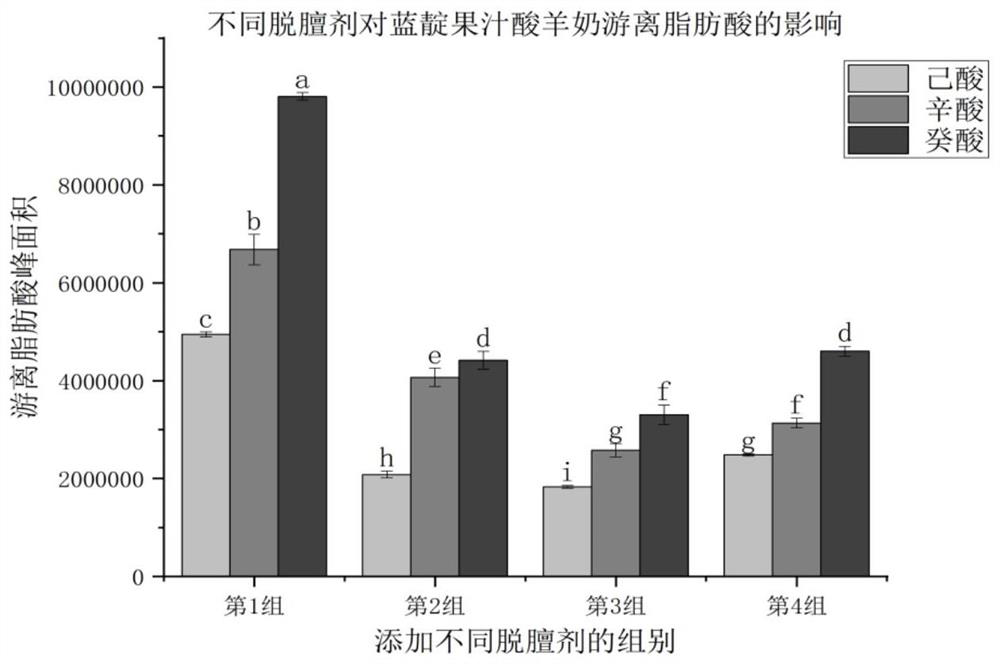

[0095] (1) Pasteurization: sterilize fresh goat milk at 65°C for 30 minutes;

[0096] (2) Stain-removing: according to the ratio of raw materials in Table 4, mix the goat milk and the smear-removing agent, and shake and stir at 35°C for 30 minutes.

[0097] Table 4 Stain removal agent and raw material proportioning

[0098]

[0099]

[0100] Wherein, the heating of the whey protein isolate is as follows: after adding the deodorizing agent, adding a heat treatment step before shaking and stirring, the temperature of the heat treatment is 65° C., and the time is 30 minutes.

[0101] (3) Homogenize the goat milk prepared in step (2) under a pressure of 20 MPa to obtain demutated goat milk.

[0102] (4) Goat milk without puffed whey protein isolate was used as the control group and groups 1 to 15 were numbered 1 to 16 for sensory evaluation, of which No. 1 was the control group, No. 2 was the first group, and so on , the results are shown in Table 5. The comprehensive eva...

Embodiment 3

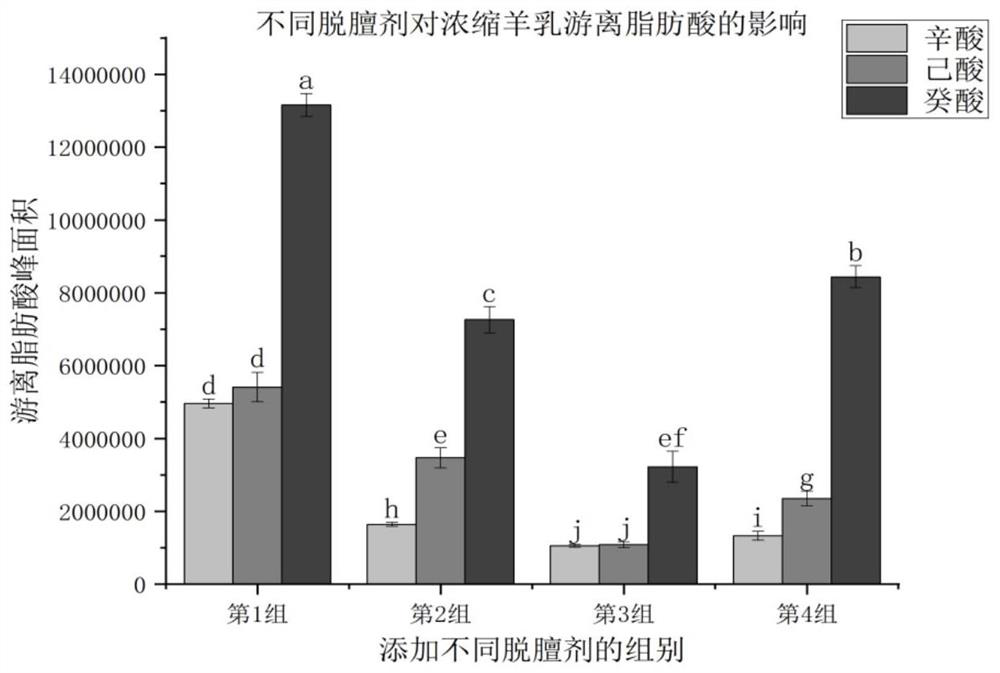

[0118] (1) Pasteurization: the homogenized goat milk was sterilized at 65° C. for 30 minutes.

[0119] (2) According to the ratio of raw materials in Table 7, after mixing goat milk and deodorization agent, shake and stir at 35°C for 30min; The composition of whey protein isolate is compressed and expanded, and its different compounding ratios are changed.

[0120] Table 7 Stain-removing agent and raw material proportioning

[0121]

[0122]

[0123] (3) Homogenize the goat milk prepared in step (2) under a pressure of 20 MPa to obtain demutated goat milk.

[0124] (4) Taking the goat milk without adding deodorizing agent as the control group, the sensory evaluation was carried out with groups 1 to 7, renumbered as Nos. 1 to 8, of which No. 1 was the control group and No. 2 was the first group , and so on, the results are shown in Table 8. The comprehensive evaluation results after fuzzy mathematics processing are shown in Table 9.

[0125] Table 8 Sensory evaluation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com