Automatic asphalt laying method

An automatic laying and asphalt technology, applied in roads, road repairs, roads, etc., can solve the problems of labor consumption, lower laying uniformity, and low laying efficiency, so as to save manpower, improve laying efficiency, and improve laying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

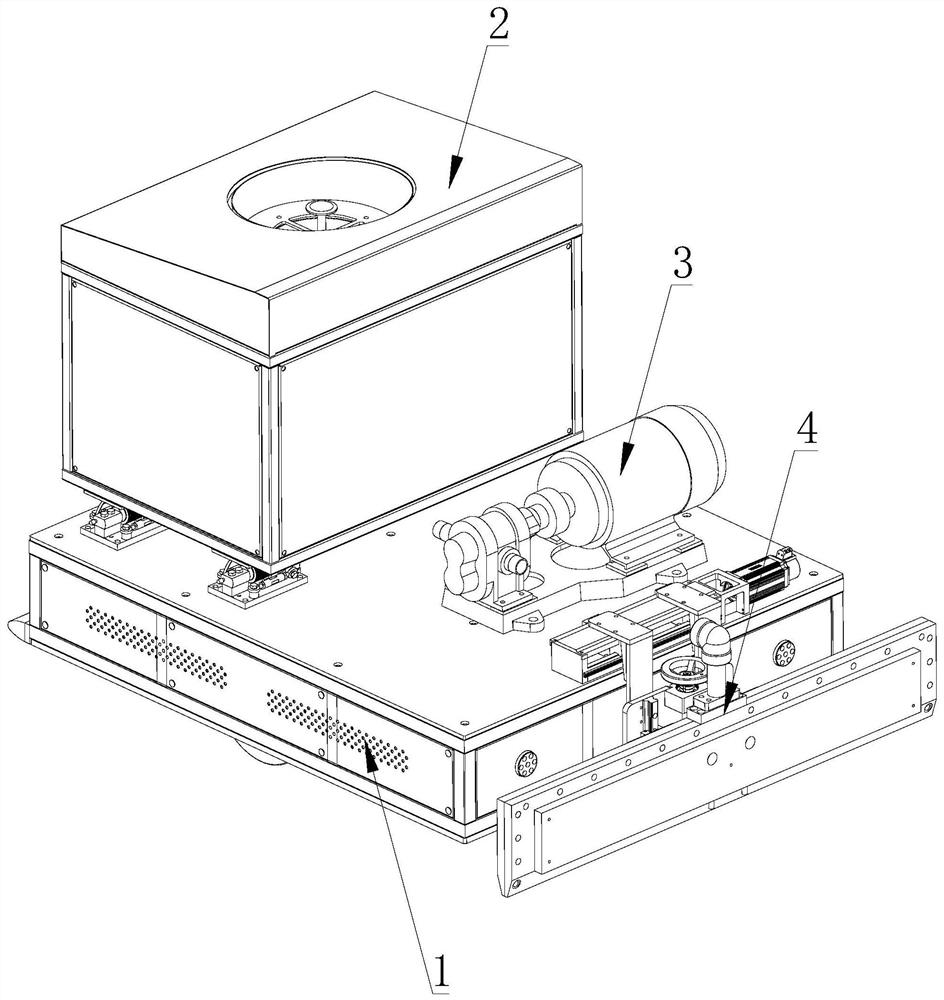

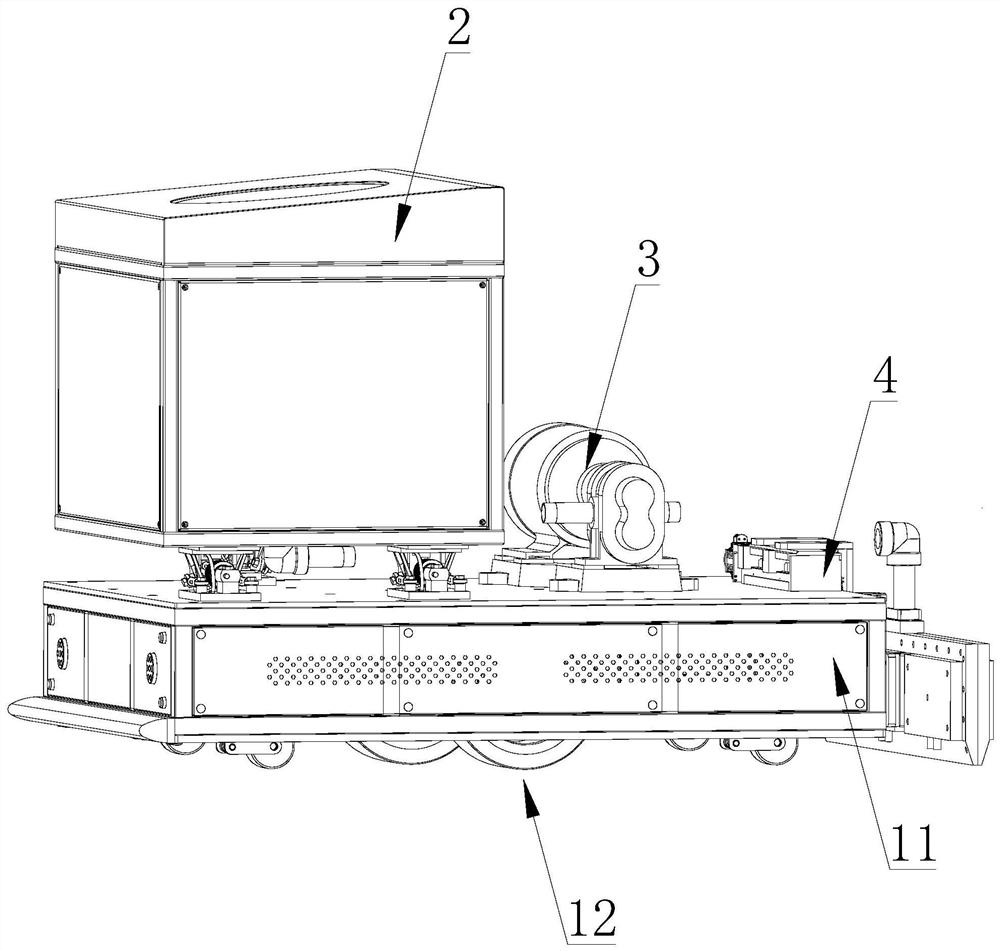

[0055] Referring to the figure, this embodiment discloses a method for automatically laying asphalt. An asphalt construction robot is used to lay asphalt. The asphalt construction robot includes a walking drive device 1, an asphalt storage tank 2, an electric pump 3 and an asphalt extruder 4.

[0056] Walking drive device 1 comprises frame 11, and the bottom end of frame 11 is provided with a plurality of wheel assembly 12, and frame 11 is provided with vision assembly 13, and vision assembly 13 is electrically connected with wheel assembly 12, asphalt storage box 2, electric pump 3 and the asphalt extruder 4 are arranged on the frame 11, and the electric pump 3 is located between the asphalt storage tank 2 and the asphalt extruder 4, the asphalt storage tank 2 is located at the front end of the frame 11, and the asphalt extruder 4 is located at the machine The rear end of the frame 11, the front end and the rear end are respectively to the two ends of the frame 11 along the le...

Embodiment 2

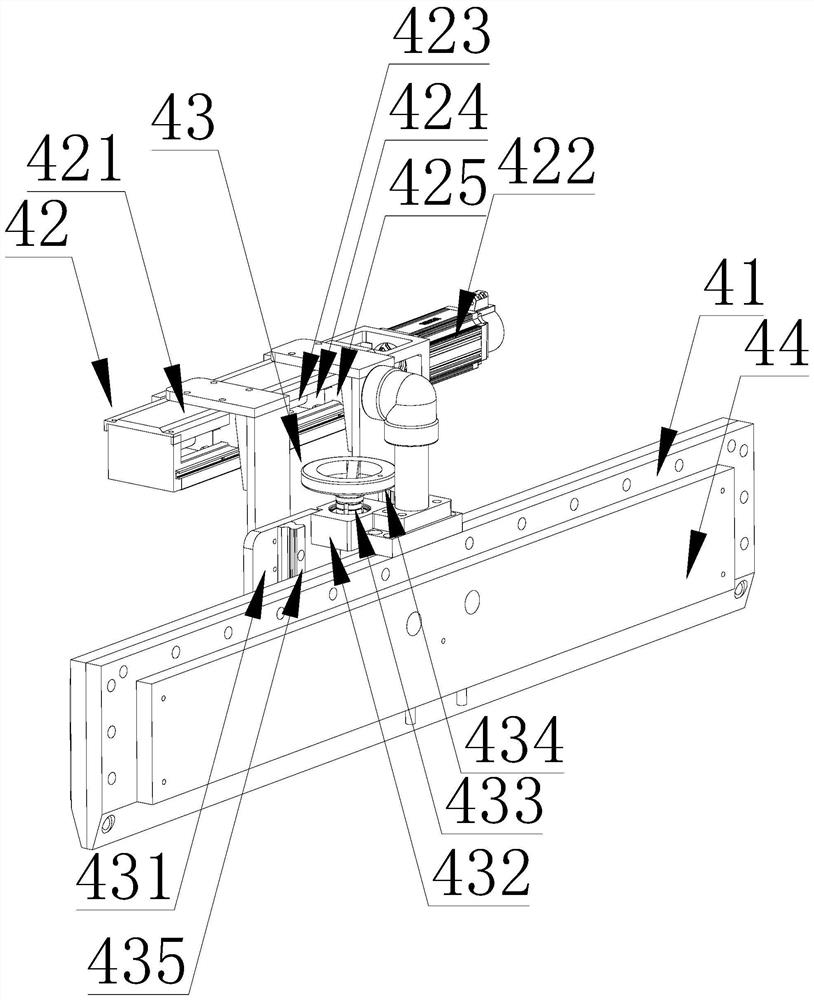

[0100] This embodiment only describes the different technical features from Embodiment 1, and the rest of the technical features are the same as Embodiment 1. In this embodiment, refer to Figure 9-10 , the adjustment device also includes an angle adjustment assembly 45, the angle adjustment assembly 45 is connected with the level adjustment assembly 42, the height adjustment assembly 43 is connected with the angle adjustment assembly 45, the asphalt extrusion die head 41 is connected with the angle adjustment assembly 45, and the angle adjustment assembly 45 can be To adjust the angle at which asphalt flows out from the asphalt extrusion die 41, the angle adjustment assembly 45 is arranged on the moving block 425, the angle adjustment assembly 45 includes a turbine 453 and a worm 452, and both sides of the installation seat 421 along the length direction are provided with moving blocks 425 The moving block 425 is provided with a rotating shaft 451, and the axis of the rotating...

Embodiment 3

[0102] This embodiment only describes the different technical characteristics from Embodiment 1, and all the other technical characteristics are the same as Embodiment 1. In this embodiment, the first heating device includes a third heating plate 46 and a heating cylinder, and the heating cylinder is arranged on the frame 11. Above, the third heating plate 46 is connected with the asphalt extrusion die 41, the third heating plate 46 is attached to the asphalt extrusion die 41, the asphalt extrusion die 41 is provided with threaded holes, and the third heating plate 46 is provided with There are countersunk holes corresponding to the threaded holes one by one. Screws are used to pass through the countersunk holes and threadedly connected with the threaded holes, and the asphalt extrusion die 41 is fixedly connected with the third heating plate 46. The third heating plate 46 is equipped with a heating plate. The pipeline, the heating pipeline includes an inlet and an outlet, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap