Non-dismantling formwork shear wall

A technology that avoids demolition of formwork and shear walls, applied to walls, structural elements, building components, etc., can solve the problems of inconvenient construction on site, high cost of prefabricated shear walls, hidden safety hazards, etc., and achieves low manufacturing cost and convenient The effect of large-scale popularization and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

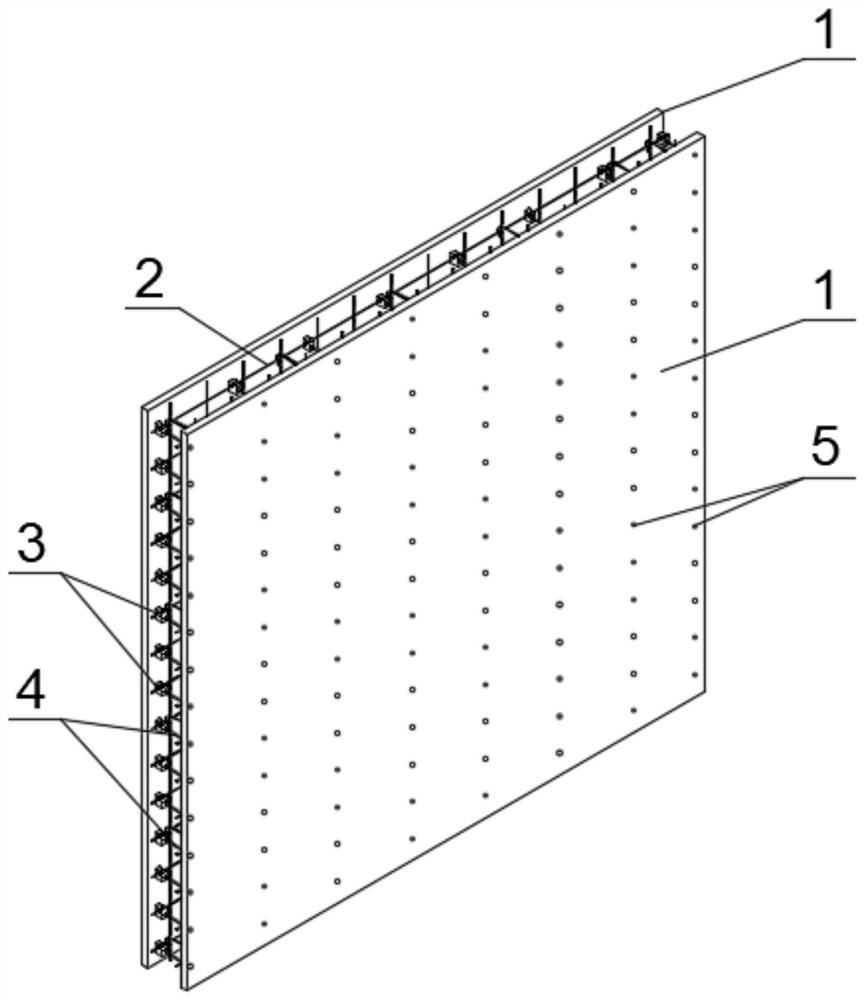

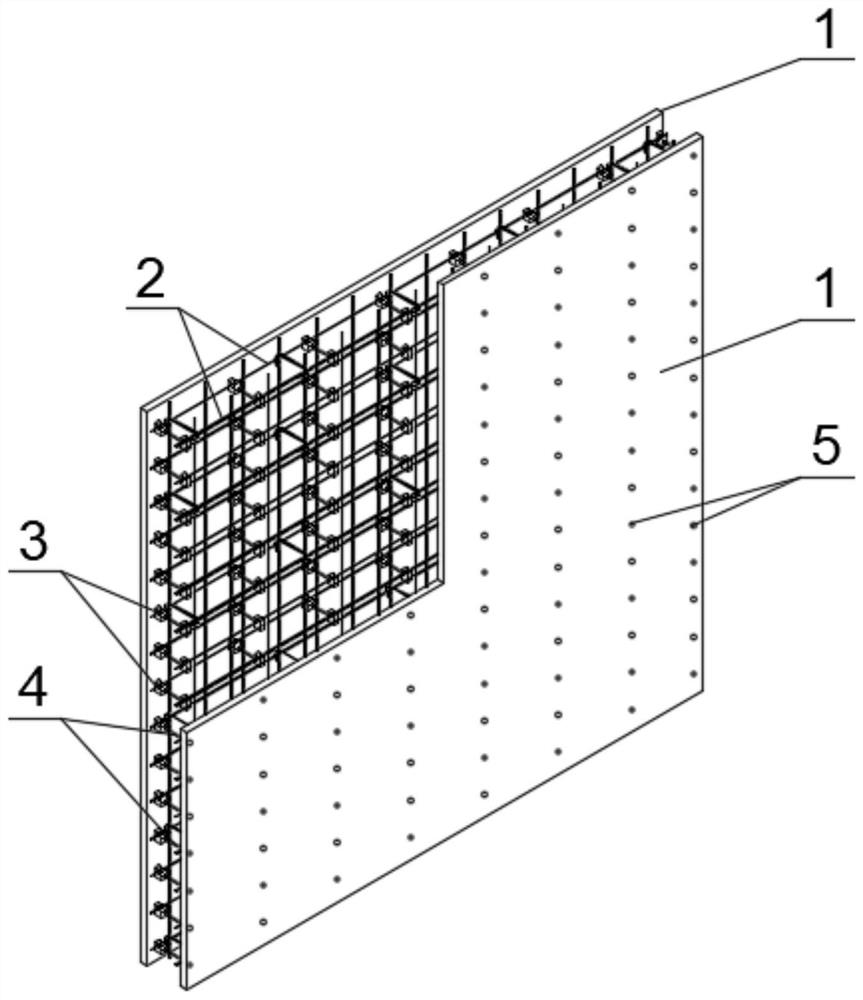

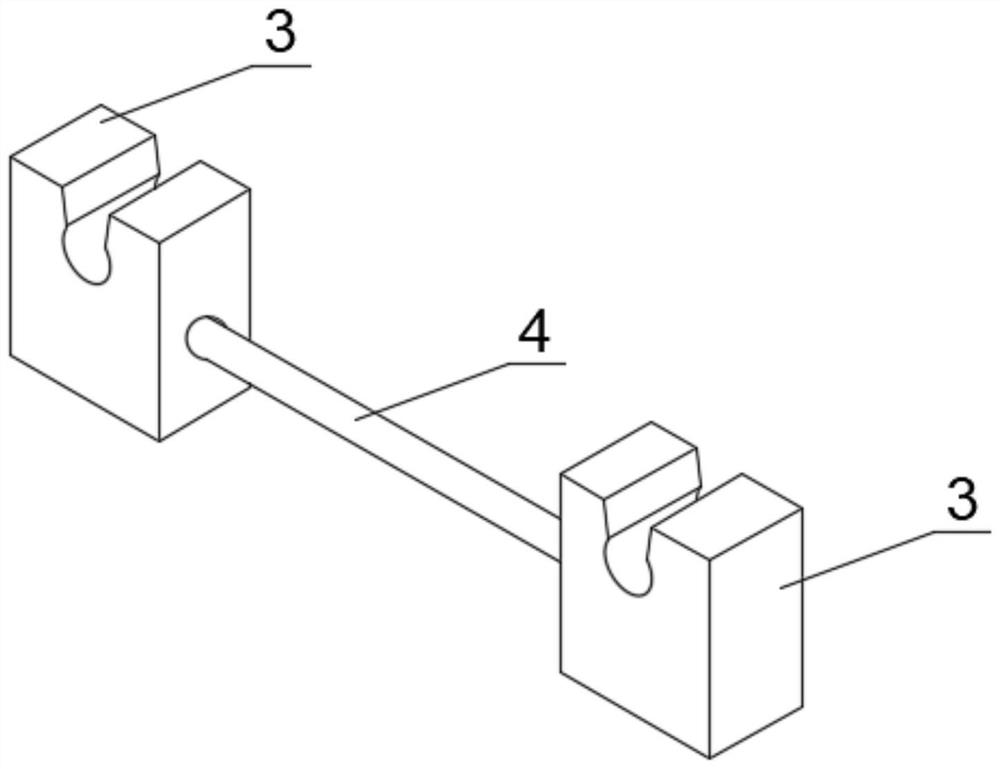

[0040]A formwork shear wall without dismantling, including high-precision formwork 1 without dismantling, steel bar molding products 2, connecting blocks 3, connecting rods 4 and self-tapping screws 5, two sets of high-precision formworks 1 without dismantling are connected by connecting blocks 3 and The connecting rod 4 is movably connected, and the two sets of high-precision non-dismantling formwork 1 are interspersed with steel bar forming products 2, and the side faces of the high-precision non-dismantling formwork 1 are arranged and interspersed with self-tapping screws 5, and the connecting block 3 and the connecting rod 4 are used for Connect and fasten the steel frame of the shear wall and the high-precision non-demolition formwork 1 on both sides. The connecting block 3 has a steel bar notch and a screw thread. Fix the connecting rod 4, the connecting rod 4 is a steel bar product, the connecting rod 4 is interspersed between the two groups of connecting blocks 3, the u...

Embodiment 2

[0042] The high-precision dismantling-free template 1 includes a template body 11, a hollow cavity 12 and a heat preservation mechanism 13. A hollow cavity 12 is provided in the middle of the template body 11, and the inner cavity of the hollow cavity 12 is arranged with a heat preservation mechanism 13. Through the hollow cavity 12 The thermal insulation mechanism 13 provided in the inner cavity can maintain the thermal insulation of the overall device while reducing the overall material consumption of the device when the inner cavity of the high-density non-disassembly formwork 1 is in a hollow state, and the manufacturing cost is relatively low. The two ends of the installation column 131 A transmission pipe 132 is installed, and the other end of the transmission pipe 132 is movably connected with the internal material mechanism 133. The internal material mechanism 133 includes a movable shell 1331 and an inner insertion mechanism 1332, and the inner cavity of the movable cas...

Embodiment 3

[0044] Mounting fan pieces 13312 are installed on both ends of the assembly connection vertical cylinder 13311. Due to the opening of the assembly connection vertical cylinder 13311 and the installation fan piece 13312, the overall device can have a certain deformation ability, and the device will not expand under the condition of thermal expansion and contraction. Damaged when subjected to expansion and contraction of the shell. The installation column 131 is interspersed with the inner cavity of the high-precision non-disassembly formwork 1, which can support the whole formwork plate body 11 and increase the stability of the device. The inner interpenetrating mechanism 1332 includes an interspersed cylinder 13321, a connecting box 13322, and an inner plug cavity 13323 and the inner material column 13324, the edge of the insertion cylinder 13321 is provided with a connecting box 13322, the inner cavity of the insertion cylinder 13321 is provided with an inner plug cavity 13323...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com