Single-inclined-strut large-span floor structure system

A supporting structure and diagonal bracing technology, which is applied to floors, building components, building structures, etc., can solve the problems of high floor structure weight ratio, complicated construction of beam intersection nodes, poor economic performance, etc., and achieve indoor space ratio High efficiency, reduced resource consumption, good overall economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

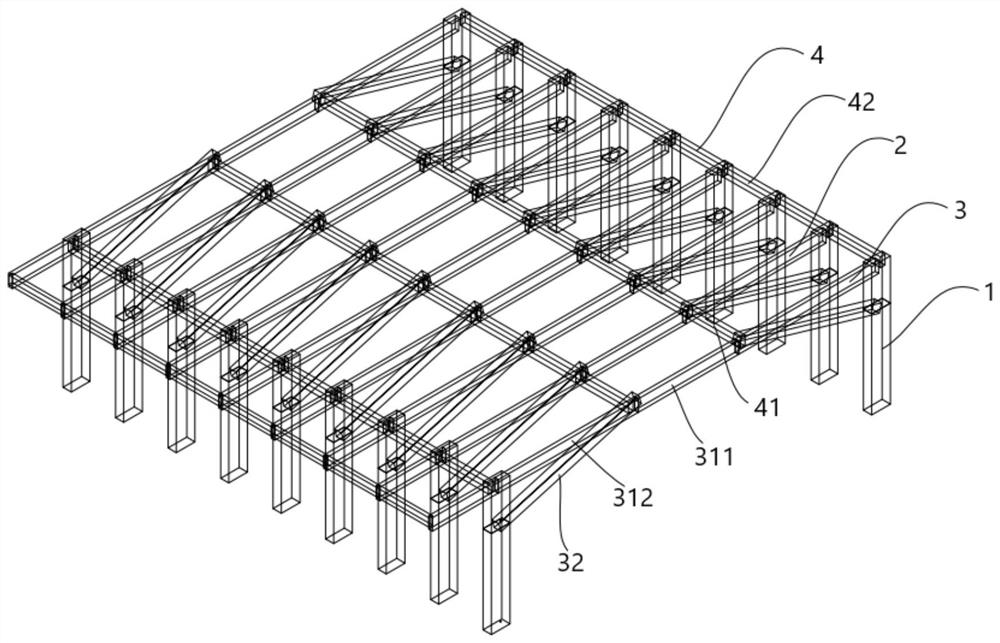

[0038] When the length-span ratio of the large-span space is greater than 2, the horizontal support frame 3 should be arranged in one-way and multiple lanes. The horizontal support frame 3 adopts a one-way multi-channel arrangement, and several horizontal support frames 3 are arranged in sequence along the direction with a longer span, and corresponding support columns are supported under the two ends of the horizontal support frame 3, and the connecting support beams 4 are vertically connected Several horizontal support frames 3 can further improve the structural stability and bearing capacity of the horizontal support frames 3 .

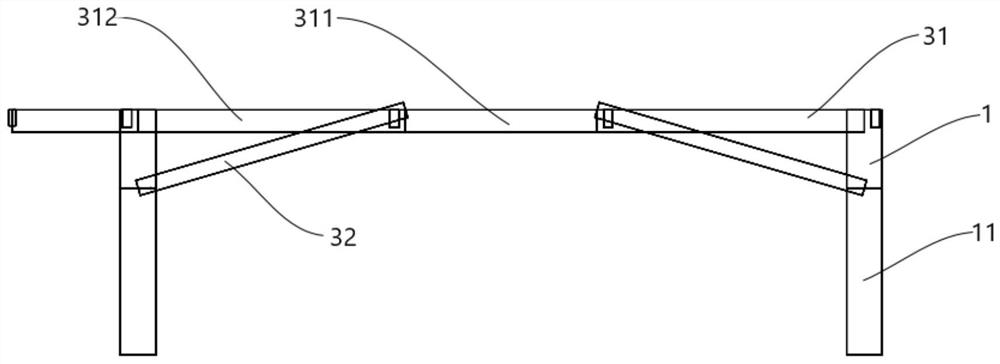

[0039] In preferred embodiment 1, the support structure 1 is provided with floor support columns 11, and the spacing between the floor support columns 11 is set at half of the normal column span of 8-10m, which meets the standards of floor construction and is safe. Higher, and support the horizontal support frame 3 on the floor support column 11. ...

Embodiment 2

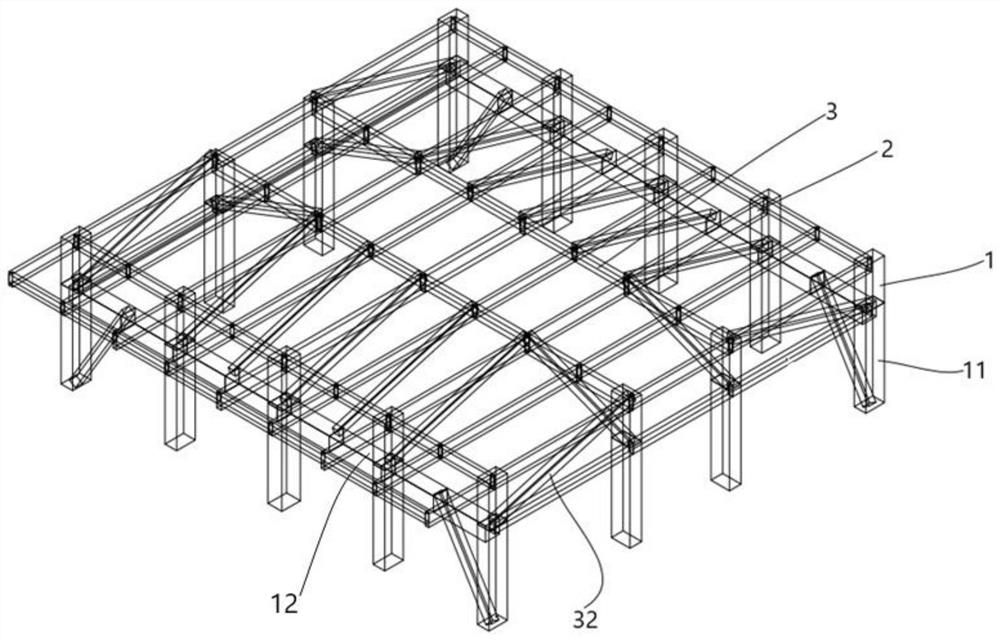

[0044] Compared with Embodiment 1, the horizontal support frame 3 is arranged differently in Embodiment 2. When the long-span ratio of the large-span space is not greater than 2, the horizontal support frame 3 should be arranged in two-way and multiple lanes. Several horizontal support frames 3 are vertically arranged along the horizontal and vertical directions of the floor structure, and the corresponding vertical support structures are supported below them.

[0045] In preferred embodiment 2, the span-to-height ratio of the upper chord horizontal support beam 31 is also taken as 1 / 30 to 1 / 40 of the total span of the space, the beam width is taken as 1 / 4 to 1 / 2 of the beam height, and the end is compressed One section of the beam 32 is supported on the upper chord horizontal support beam 31, and the other end is supported on the floor support column 11 or the lower support beam 12 between the floor support columns 11. The height and width of the support section can be taken t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com