Toothed plate electric field integration device and method of electrostatic industrial fan

An integrated device, electrostatic technology, applied in the field of tooth plate electric field integrated device, can solve the problems of less electrostatic adsorption, untimely detection, loss, etc., achieve the effect of increasing contact time, reducing gas flow rate, and improving treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

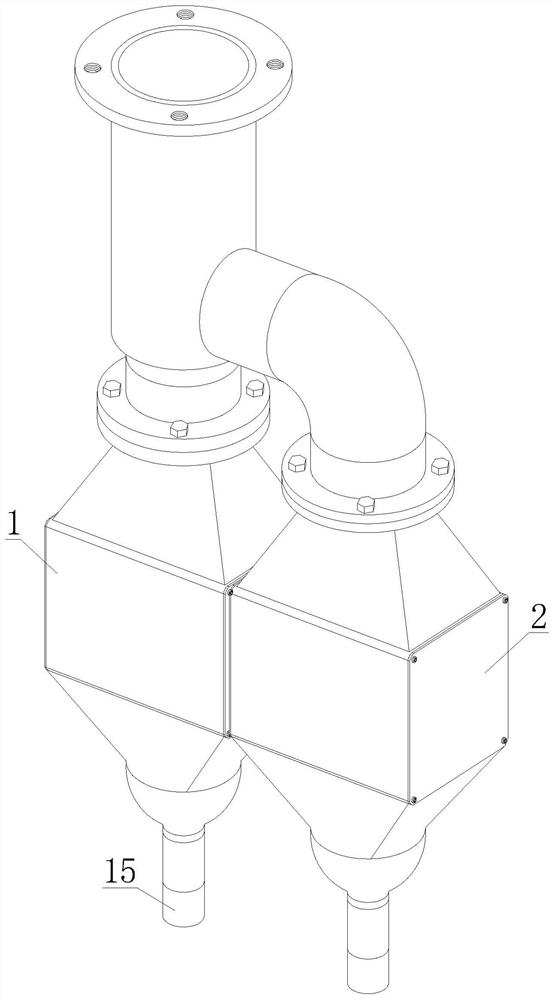

[0041] Another technical solution proposed by the present invention: to provide an implementation method of the tooth plate electric field integration device of the electrostatic industrial fan, including the following steps:

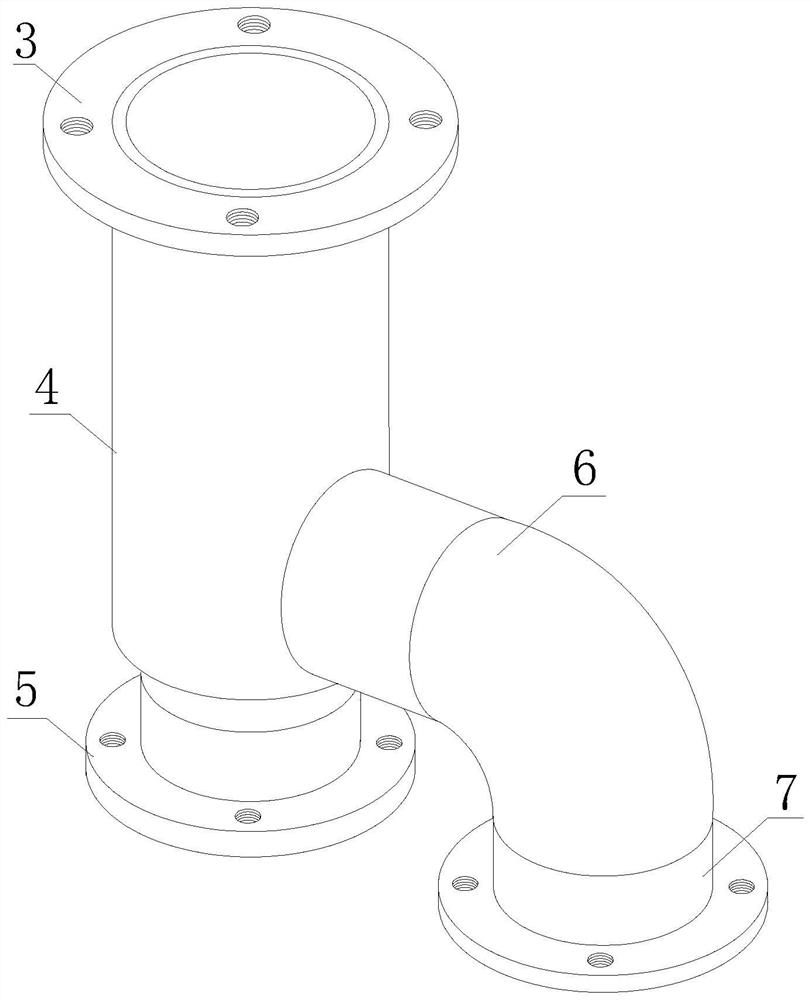

[0042] Step 1: Connect the connecting flange 3 to the air outlet of the industrial fan, connect the first tooth plate electric field integration mechanism 1 to the first conducting member 5, and connect the second tooth plate electric field integration mechanism 2 to the second conducting member 7 connect;

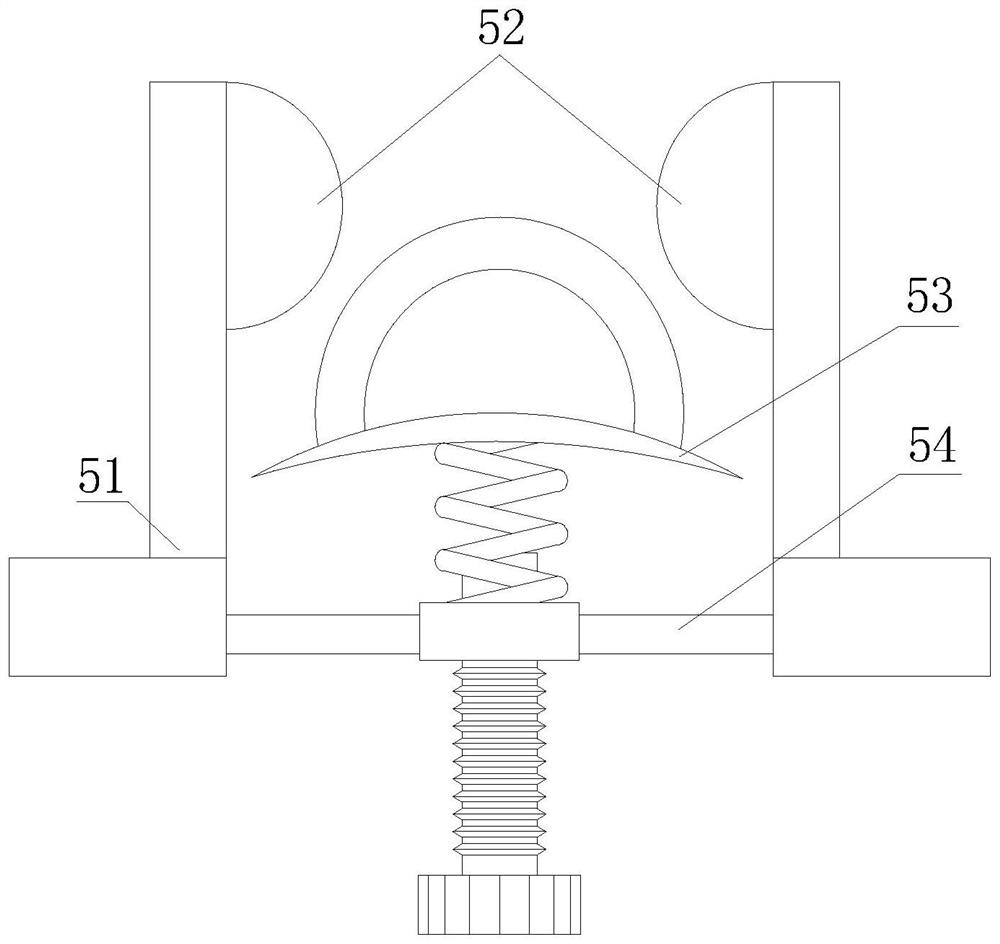

[0043] Step 2: The dust blown out by the industrial fan flows through the main conduit 4 to the first conduit 5 and the second conduit 7. Under wind pressure, the movable seal 53 of the first conduit 5 is completely opened, and the second conduit 5 is completely opened. The movable seal 53 of the through piece 7 is partially opened, a large amount of dust is continuously injected into the first tooth plate electric field integration mechanism 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com