Lithium battery positive electrode material and production process thereof

A positive electrode material and production process technology, applied in the field of lithium battery positive electrode materials and its production process, can solve problems such as differences in heating, faults in lithium battery positive electrode materials, and poor product consistency, achieving good consistency, good uniformity, and improved The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of LiNi 0.5476 co 0.1195 mn 0.3286 Zr 0.0043 o 2 The production process of positive electrode material comprises the following steps:

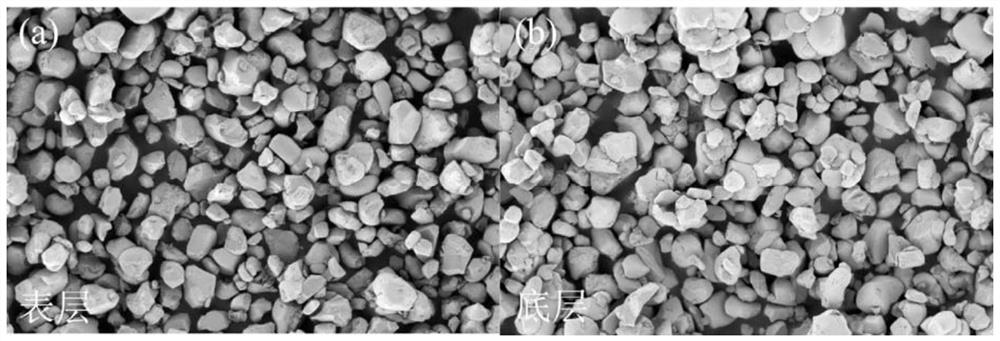

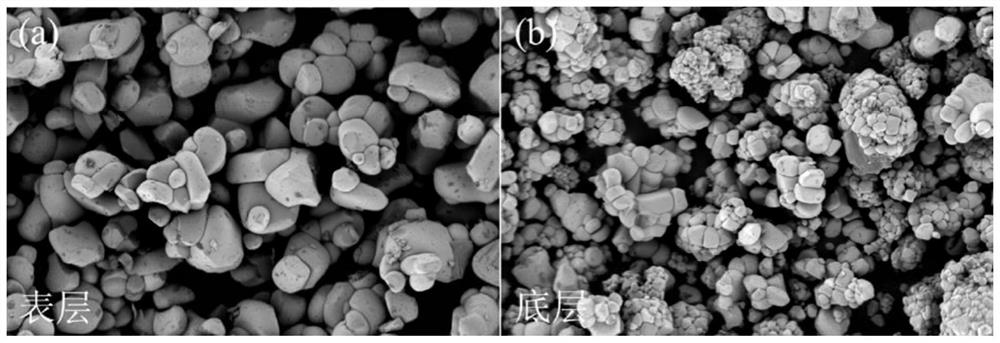

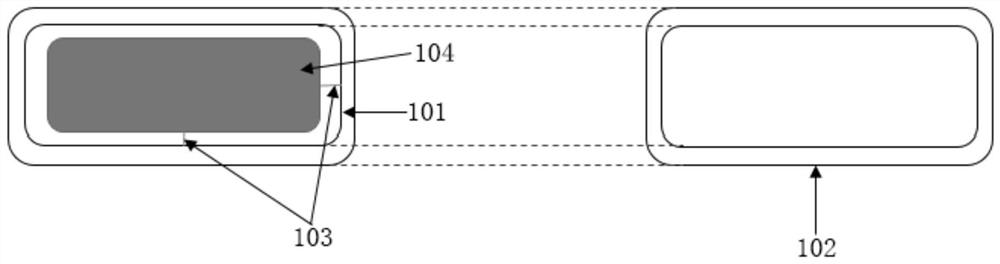

[0030] (1) Test temperature difference: the Ni of 10000 parts by weight 0.55 co 0.12 mn 0.33 (OH) 2 Precursor, lithium carbonate of 4250 parts by weight and ZrO of 36 parts by weight 2 Mix well, put into a sagger, and at the same time as image 3 As shown, two temperature measuring coffins 101 equipped with temperature measuring blocks 104 are respectively embedded in the bottom layer and the surface layer of the material during the bowl loading process. The amount of material is 1 row, and 8 emptying saggers are fed into the front and back of the feeding sagger to bring temperature, so as to ensure that the temperature of the material is basically the same as that of the material when the kiln continues to feed, and then in the aerobic atmosphere Carry out high-temperature sintering, wherein the temperature measuring c...

Embodiment 2

[0035] A kind of LiNi 0.6438 co 0.06933 mn 0.2773 Zr 0.0037 Al 0.0058 o 2 The production process of positive electrode material comprises the following steps:

[0036] (1) Test temperature difference: the Ni of 10000 parts by weight 0.65 co 0.08 mn 0.27 (OH) 2 Precursor, lithium hydroxide of 4640 parts by weight and ZrO of 29 parts by weight 2 , 19 parts by weight of Al 2 o 3 Mix well, put into a sagger, and at the same time as Figure 4As shown, two temperature measuring coffins 101 equipped with temperature measuring rings 105 are respectively embedded in the bottom layer and the surface layer of the material during the bowl loading process. The amount of material is 1 row, and 8 emptying saggers are fed into the front and back of the feeding sagger to bring temperature, so as to ensure that the temperature of the material is basically the same as that of the material when the kiln continues to feed, and then in the aerobic atmosphere Carry out high-temperature ...

Embodiment 3

[0041] A kind of LiNi 0.6904 co 0.0493 mn 0.2466 Zr 0.0042 Al 0.0054 B 0.0042 o 2 The production process of positive electrode material comprises the following steps:

[0042] (1) Test temperature difference: the Ni of 10000 parts by weight 0.70 co 0.05 mn 0.25 (OH) 2 Precursor, lithium hydroxide of 4780 parts by weight and ZrO of 36 parts by weight 2 , 19 parts by weight of Al 2 o 3 , 10 parts by weight of B 2 o 3 Mix evenly and put it into a sagger. During the filling process, two temperature-measuring coffins equipped with temperature-measuring blocks are buried in the bottom layer and surface layer of the material respectively. The amount of material is 1 row, and 8 emptying saggers are fed into the front and back of the feeding sagger to bring temperature, so as to ensure that the temperature of the material is basically the same as that of the material when the kiln continues to feed, and then in the aerobic atmosphere High temperature sintering, in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com