Desulfurization and denitrification device and method

A technology of desulfurization, denitrification, and desulfurization chamber, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as increasing work costs, affecting reaction efficiency, and reducing work quality, so as to reduce processing costs and ensure reaction quality. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

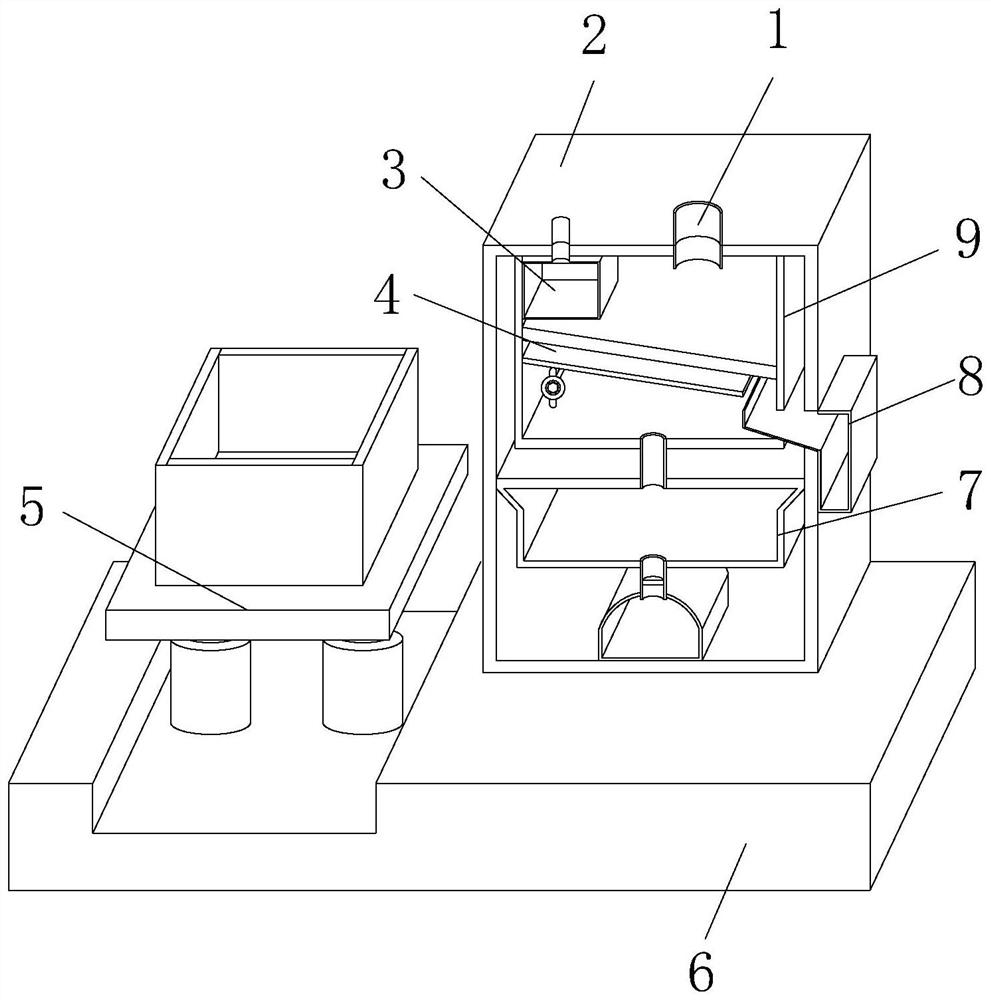

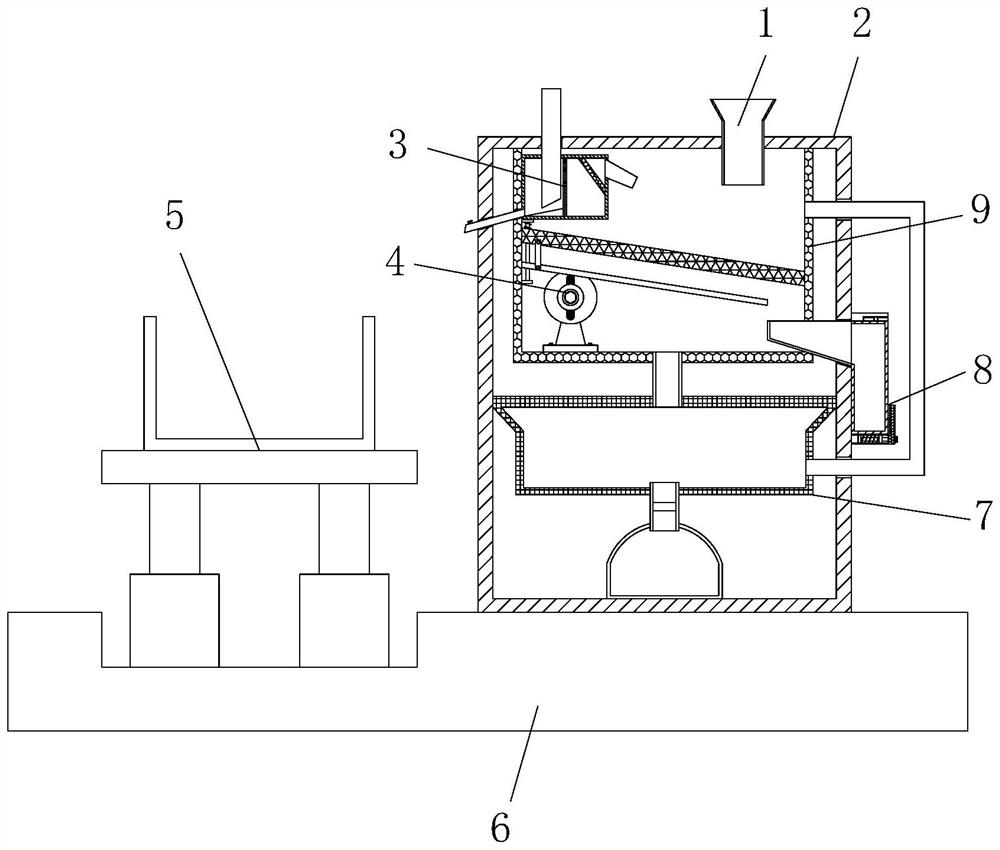

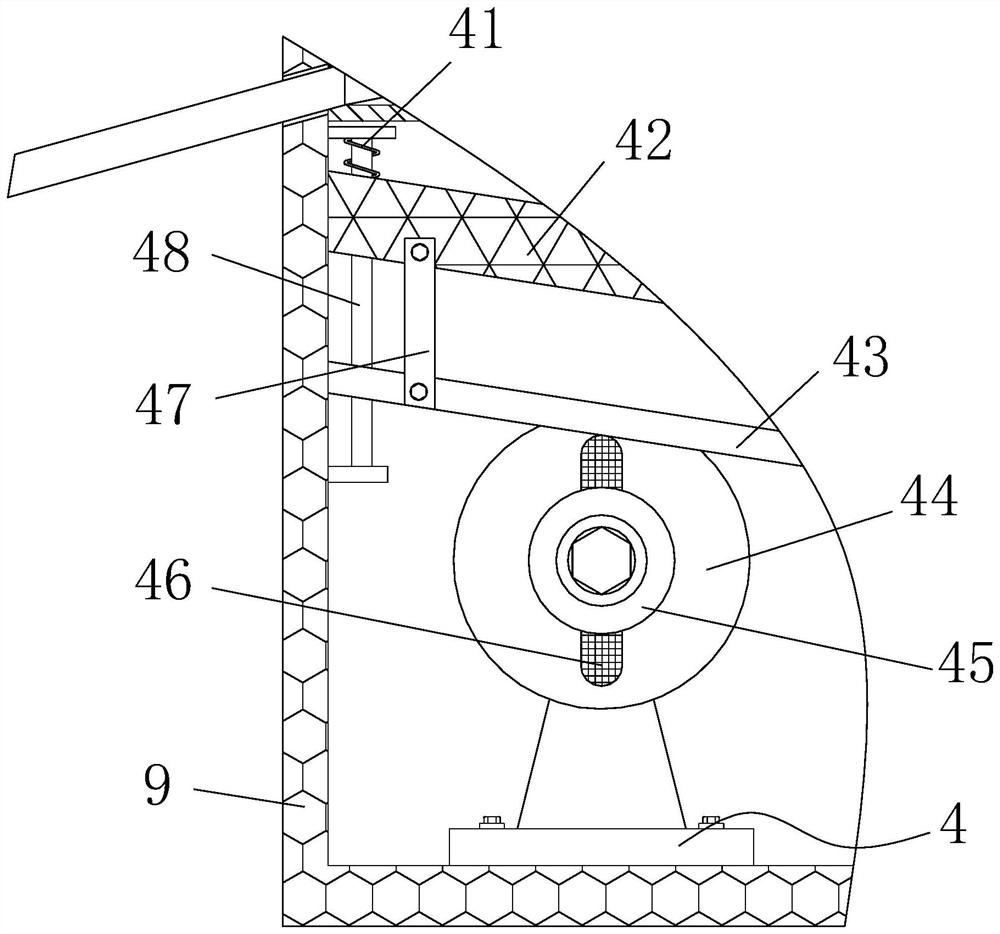

[0033] see Figure 1-5 , the present invention provides the following technical solutions: a desulfurization and denitrification device, including a base 6, a lifting platform 5 is provided on one side of the upper end of the base 6, a working box 2 is provided on one side of the lifting platform 5, and the upper end of the working box 2 is connected to There is a feed pipe 1, the bottom end of the feed pipe 1 is provided with a desulfurization chamber 9, the bottom end of the desulfurization chamber 9 is provided with a denitrification chamber 7, and the inside of the desulfurization chamber 9 is provided with a vibration cleaning assembly 4, which includes a catalyst net 42. Collecting baffle 43, stepping motor 44, rotating block 45, protruding block 46, connecting frame 47 and guide rod 48, wherein, the inner bottom of desulfurization chamber 9 is provided with stepping motor 44, and the stepping motor 44 The output end is connected with a rotating block 45, and the surface...

Embodiment 2

[0040]The difference between this embodiment and Embodiment 1 is that specifically, one side of the working box 2 is provided with a convenient collection assembly 8 corresponding to the vibration cleaning assembly 4, and the convenient collection assembly 8 includes a guide plate 81, a support frame 82, and a limit spring 83 , fixed block 84, pull rod 85, pressing plate 87, collecting box 88 and sealing plate 89, wherein, the surface side of working case 2 is provided with sealing plate 89, and the bottom end of sealing plate 89 is provided with collecting box 88, and collecting box The bottom end of 88 is provided with support frame 82, and the inside of support frame 82 is provided with fixed block 84, and the inside of fixed block 84 is provided with pull bar 85, and the surface socket of pull bar 85 is provided with limit spring 83, and pull bar 85 is far away from limit spring 83 One side of the collection box 88 is provided with a pressing plate 87, and one side of the c...

Embodiment 3

[0050] This embodiment differs from Embodiment 1 and Embodiment 2 in that: specifically, the upper end of the working box 2 is provided with an air intake processing assembly 3, and the intake air processing assembly 3 includes an air intake pipe 31, a sewage pipe 32, a flow guide Block 33, water washing box 34, air outlet pipe 35, porous baffle plate 36 and grid filter screen 37, wherein, the inner upper end of work box 2 is connected with air inlet pipe 31, and the bottom end of air inlet pipe 31 is provided with water washing box 34, and water washing box 34 is provided with a grid filter screen 37 in the middle of the inside, and the bottom end of one side of the grid filter screen 37 is provided with a diversion block 33, and the side of the washing tank 34 near the flow guide block 33 is connected with a sewage pipe 32, and the grid filter screen 37 is provided with a porous baffle 36 away from the side of the deflector block 33 , and an air outlet pipe 35 is provided at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com