Through hole filling manufacturing process of multilayer board

A production process and multi-layer board technology, which is applied in the fields of printed circuit manufacturing, electrical connection formation of printed components, electrical components, etc., can solve the problems affecting product reliability and copper thickness uniformity, unfavorable fine line production, and restricted space utilization, etc. problems, to achieve the effect of facilitating the production of precision circuits, reducing the reliability risk in the hole, and avoiding the grinding process of the resin plug hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

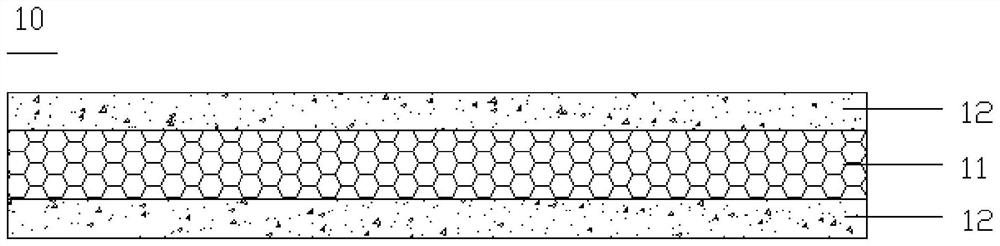

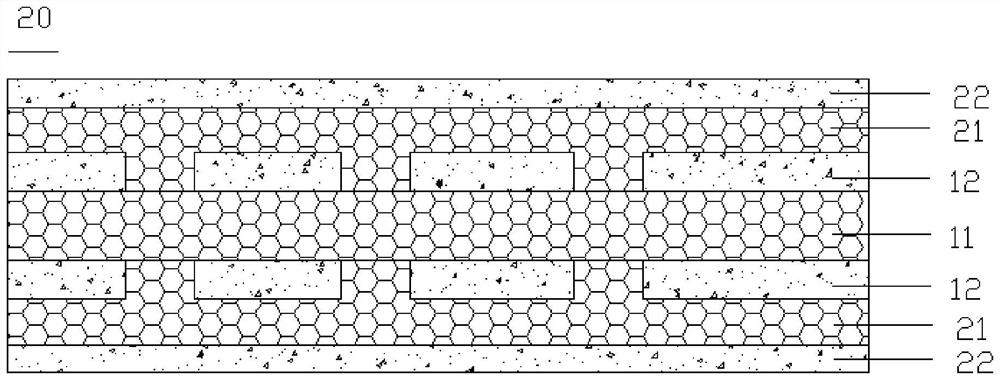

[0052] Example: such as Figure 1-8 Shown, a kind of through-hole filling manufacturing process of multi-layer board comprises the following steps:

[0053] Step 1: cutting and baking: cut a substrate of a certain size, put it in an oven and bake, the substrate 10 is a double-sided copper-clad substrate, and the double-sided copper-clad substrate has an inner insulating layer 11 and two respectively pressing the inner copper foil layer 12 on the front and back sides of the inner insulating layer; figure 1 As shown, the purpose of material cutting is to facilitate subsequent equipment processing; the baking conditions are: the temperature is 122-148°C, and the baking time is 2-4h; the substrate is baked to eliminate the stress of the substrate and prevent the substrate from warping. Improve the dimensional stability of the substrate and reduce the expansion and contraction of the substrate;

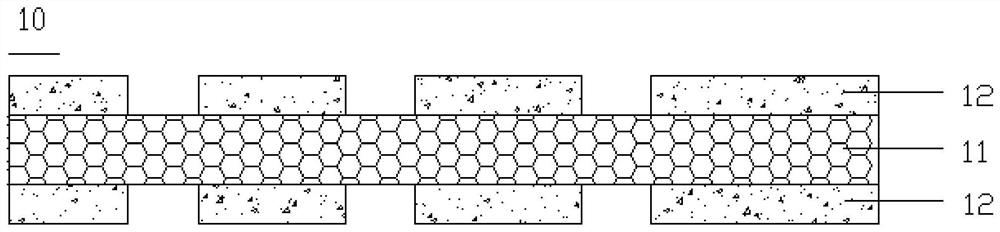

[0054] Step 2: Inner line: eg figure 2 As shown, the two inner copper foil layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com