Natural gas injection pry

A technology of natural gas and gas pipelines, applied in the direction of gas and gas/steam mixing, mixers, chemical/physical processes, etc., can solve the problems of reducing energy utilization, pressure energy loss, increasing power consumption, etc., to achieve the solution of pressure energy Loss, reduction of energy consumption and waste of resources, and the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

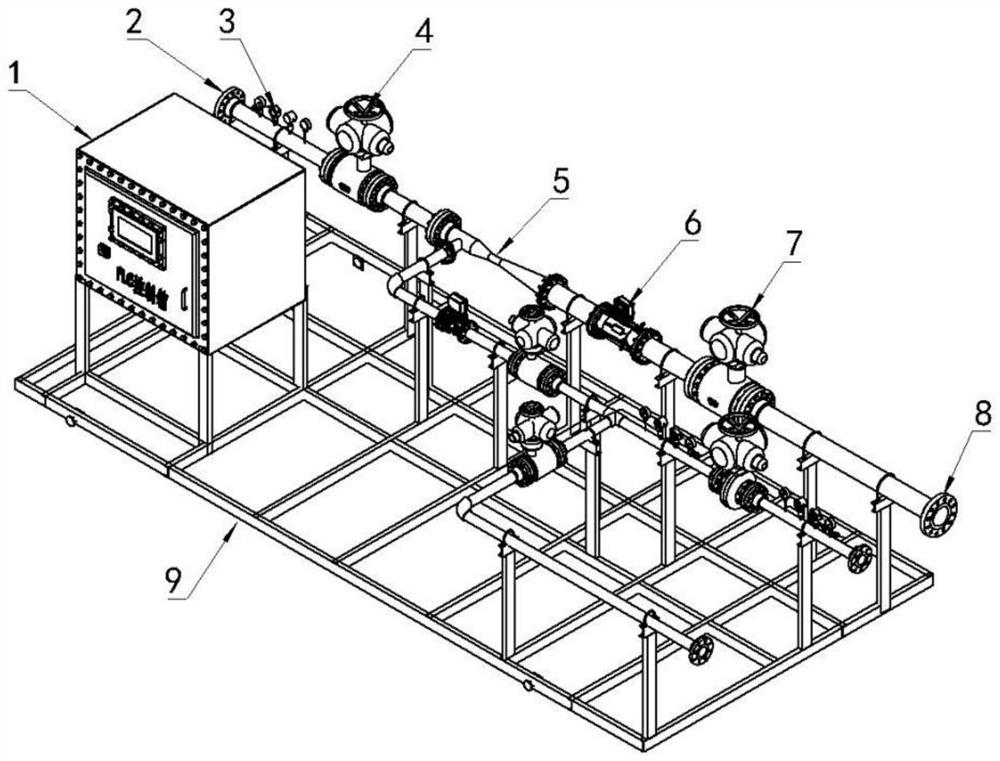

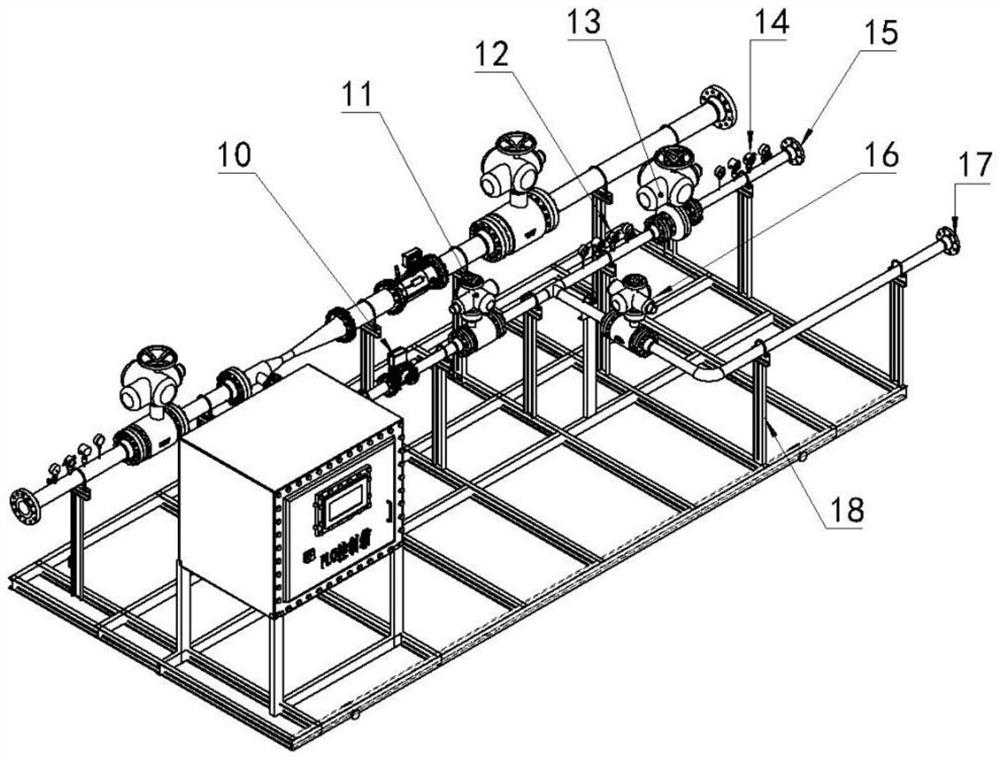

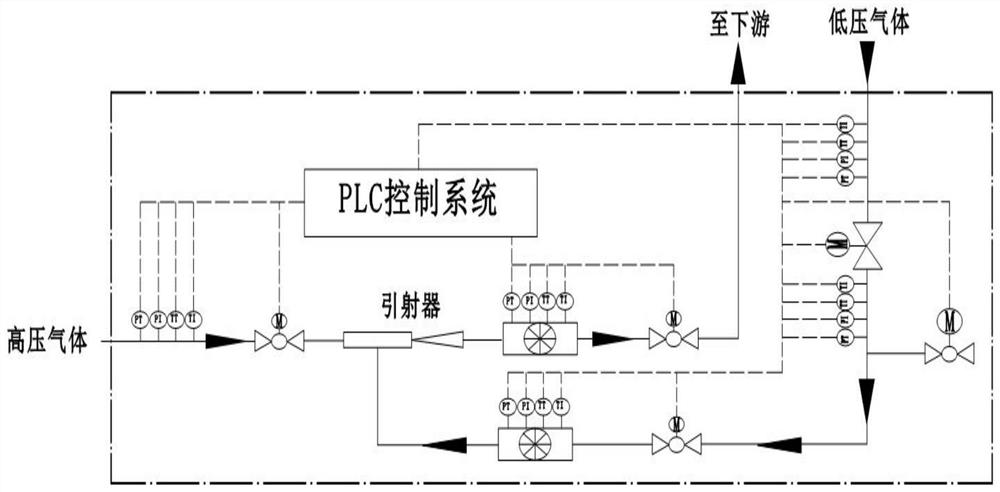

[0031] Such as Figure 1-4 As shown, a natural gas injection skid includes a high-pressure gas pipeline, a low-pressure gas pipeline, a bypass pipeline and a control device;

[0032] The high-pressure gas pipeline includes a first pipeline and a control valve one 4, an injector 5, a flow meter one 6 and a control valve two 7 arranged in sequence along the first pipeline, and the end of the first pipeline close to the control valve one 4 is connected to a high-pressure gas source , the other end of the first pipeline is connected to the downstream pipeline, and the ejector 5 is provided with a contraction section;

[0033] The low-pressure gas pipeline includes a second pipeline and flowmeter two 10, control valve three 11, and control valve four 13 arranged in sequence along the second pipeline. The end of the second pipeline near the flowmeter two 10 communicates with the inlet of the ejector 5. The other end of the second pipeline is connected to a low-pressure gas source; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com