An automatic assembly formwork for pouring concrete elements

A technology for pouring concrete and automatic assembly, which is applied to molds, ceramic forming mandrels, ceramic forming cores, etc., can solve the problems of automation of formwork assembly, tight reconstruction time, and long time consumption, and achieves good overall structural performance and production. Short cycle and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

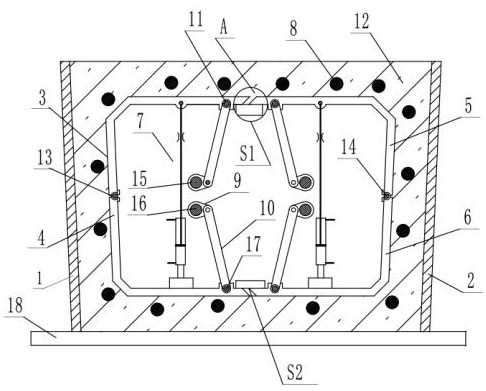

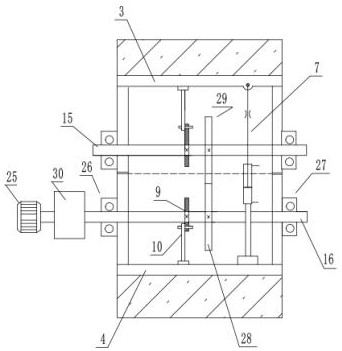

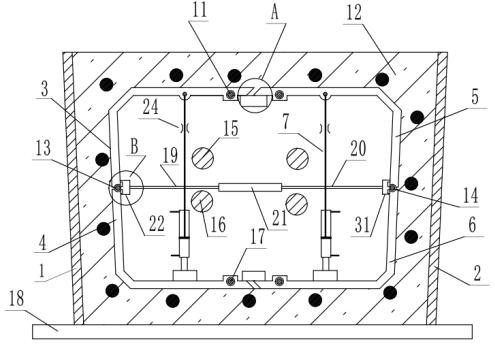

[0033] The assembly drive of the formwork requires a high torque, therefore, the rotational speed of the drive shaft is selected to be low. The first motor of the present invention

[0034] The first motor 25 of the present invention, the reducer 30, the upper left drive shaft 15, the lower left drive shaft 16, etc., all pass through

[0040] The structure of the right support seat 31 and the left support seat 22 of the present invention are the same, and the left and right are symmetrical. Therefore, the right support is not drawn.

[0053] 4. Then, insert one end of the locking bolt 37 in the locking bolt mechanism into the opening groove of the right fixing seat 36, and lock it with the locking pin 38.

[0056] 7. After the curing process is completed, the mold is removed. Open the lock bolt 37 in the lock bolt mechanism; the CPU sends out the vertical distance adjustment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com