Aircraft fuselage assembly system and assembly method

An assembly system and aircraft fuselage technology, applied in aircraft assembly and other directions, can solve the problems of low assembly quality and low assembly efficiency, and achieve the effects of improving assembly quality, efficiency, and production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

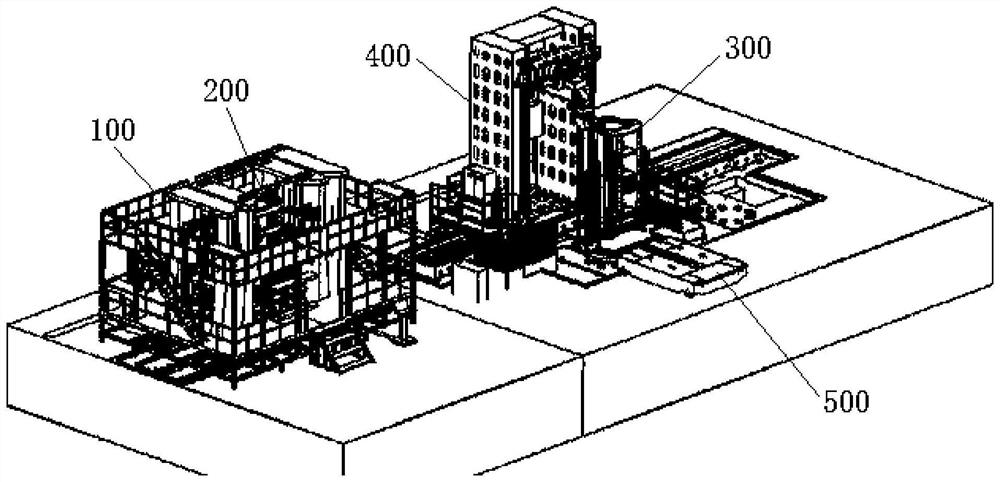

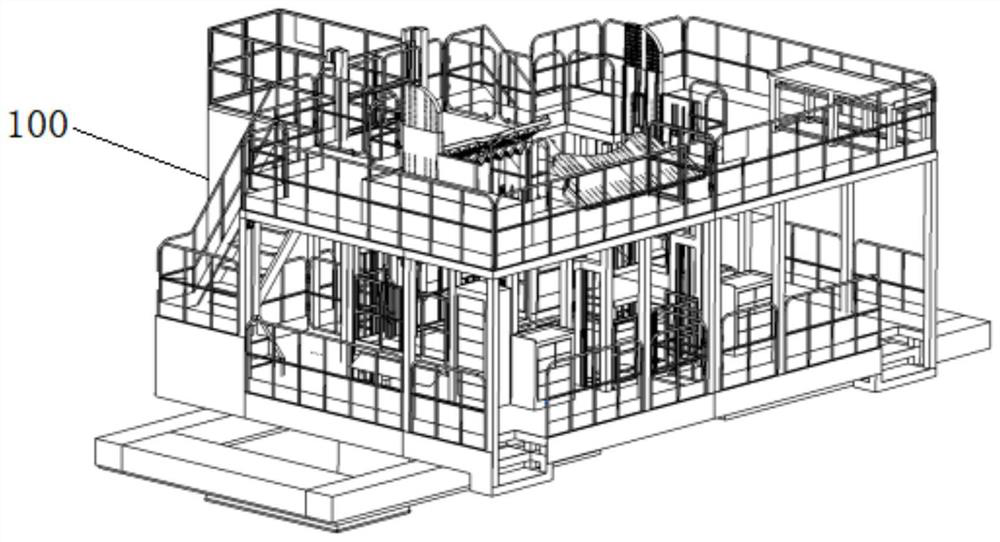

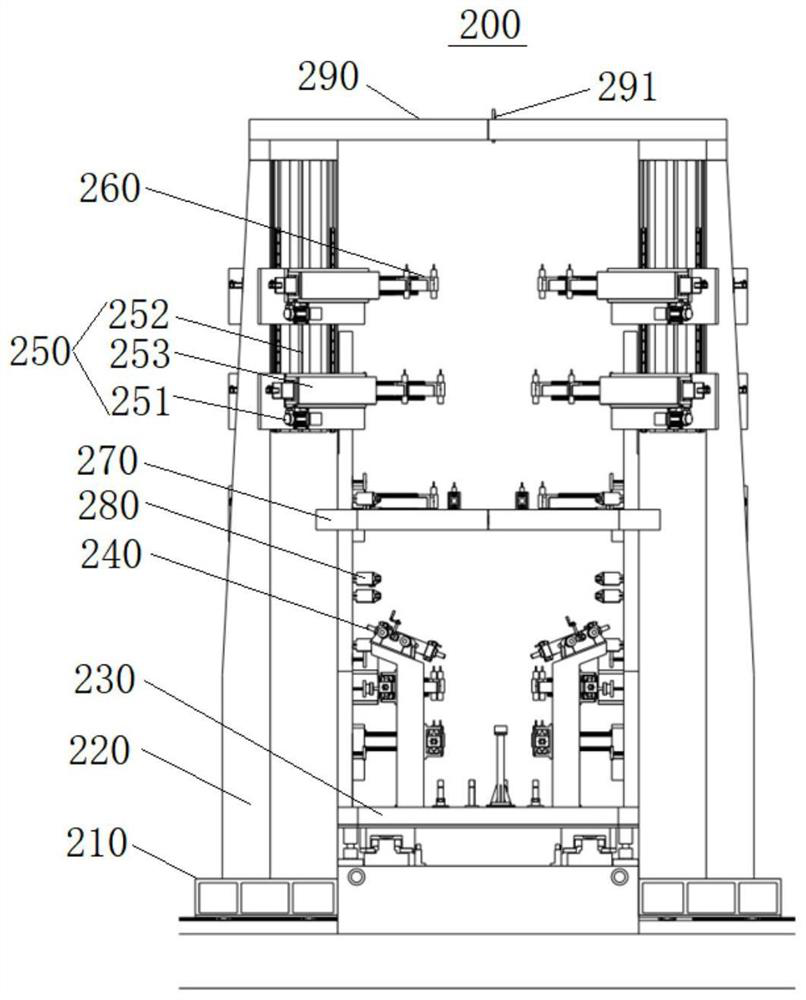

[0055] refer to Figure 1-Figure 17 , the present embodiment provides an aircraft fuselage assembly system and assembly method, including an assembly platform 100, an assembly tool 200, a positioning workbench 300, a processing machine tool 400 and an AGV trolley 500, the assembly platform 100 is used to carry staff, and the assembly tool 200 Located in the assembly platform 100, the assembly tooling 200 is used to assemble aircraft components, the positioning workbench 300 is used to clamp the assembled aircraft components, the processing machine tool 400 is used to perform drilling and riveting on the assembled aircraft components, and the AGV trolley 500 is used to Transport aircraft parts.

[0056] In this embodiment, the aircraft parts can be assembled with the help of the assembly platform 100 and the assembly tool 200. The assembly platform 100 can complete the assembly work of different heights of the large aircraft parts. At the same time, the aircraft components are...

Embodiment 2

[0083] refer to Figure 1-Figure 18 , the present embodiment provides an assembly method based on the aircraft fuselage assembly system described in Embodiment 1, comprising the following steps:

[0084] The components are transported to the assembly platform 100 by the AGV trolley 500;

[0085] Assemble the aircraft components through the assembly tooling 200 in the assembly platform 100;

[0086] Transport the assembled aircraft components to the positioning workbench 300 through the AGV trolley 500;

[0087] Install the assembled aircraft parts on the positioning workbench 300;

[0088] The positioning workbench 300 equipped with aircraft parts is transported to the processing machine tool 400 as a whole through the AGV trolley 500;

[0089] The assembled aircraft components are drilled and riveted by the processing machine tool 400 .

[0090] In this embodiment, the aircraft parts are assembled with the help of the assembly platform 100 and the assembly tool 200. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com