Polypropylene ethylene synthesis reaction kettle and use method thereof

A synthesis reaction, polypropylene technology, applied in chemical instruments and methods, mixers, fluid mixers, etc., can solve the problems of easy splashing of raw materials, hindering the up and down flow of raw materials, slowing down the synthesis speed, etc., so as to avoid uneven distribution. , to avoid the effect of unclear observation and reducing the synthesis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

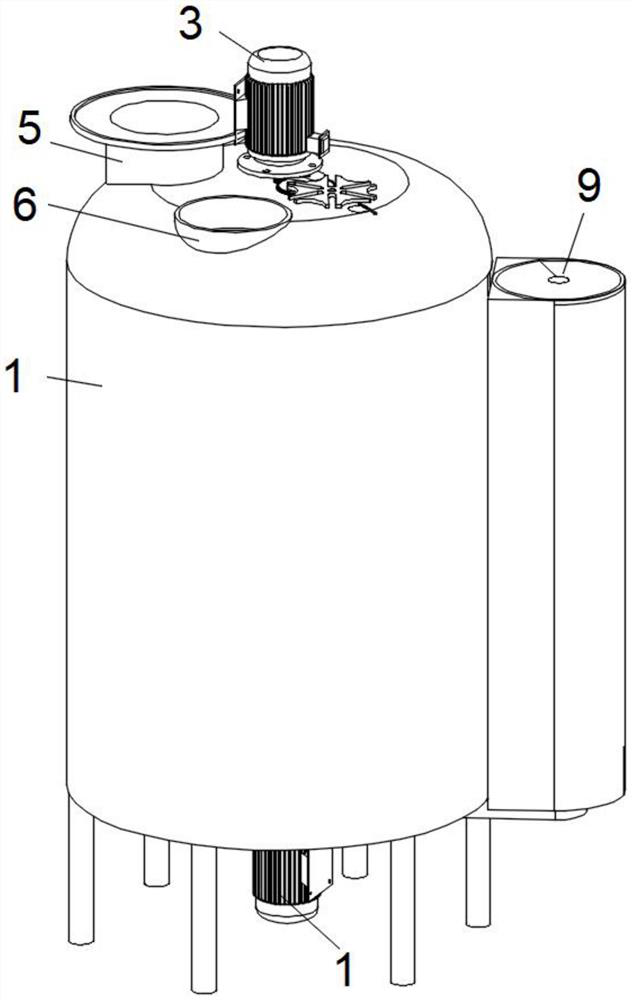

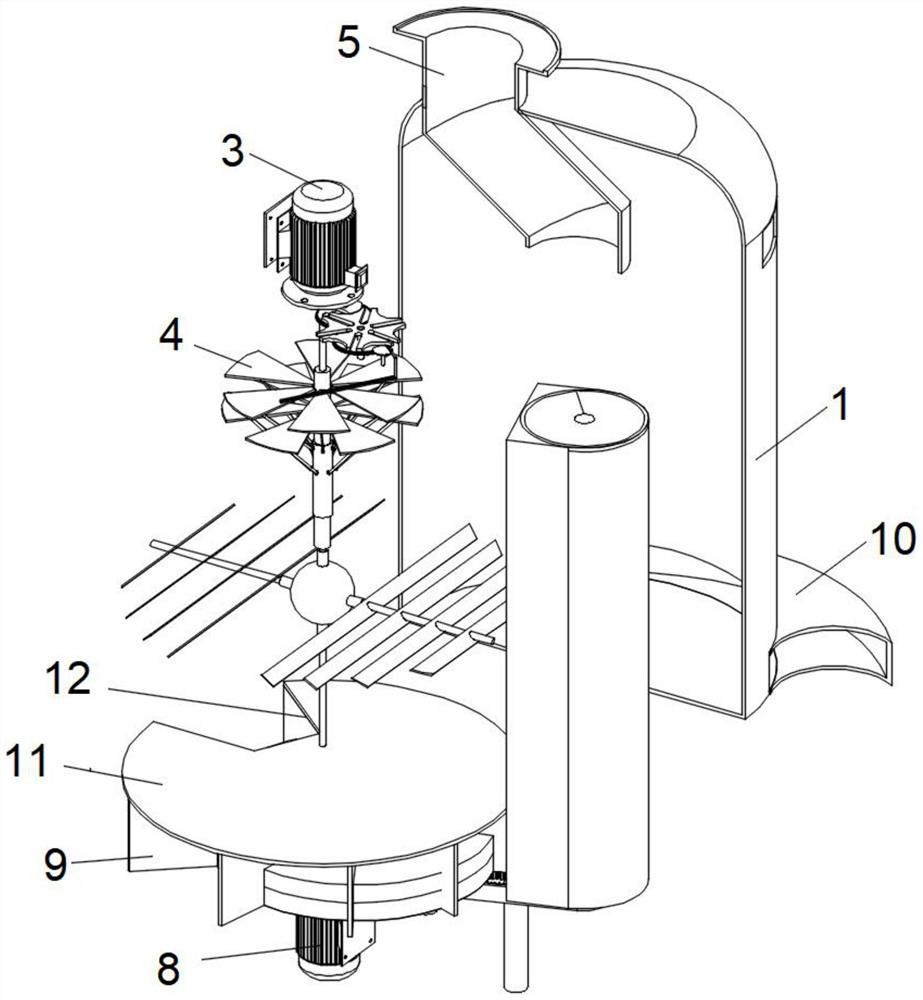

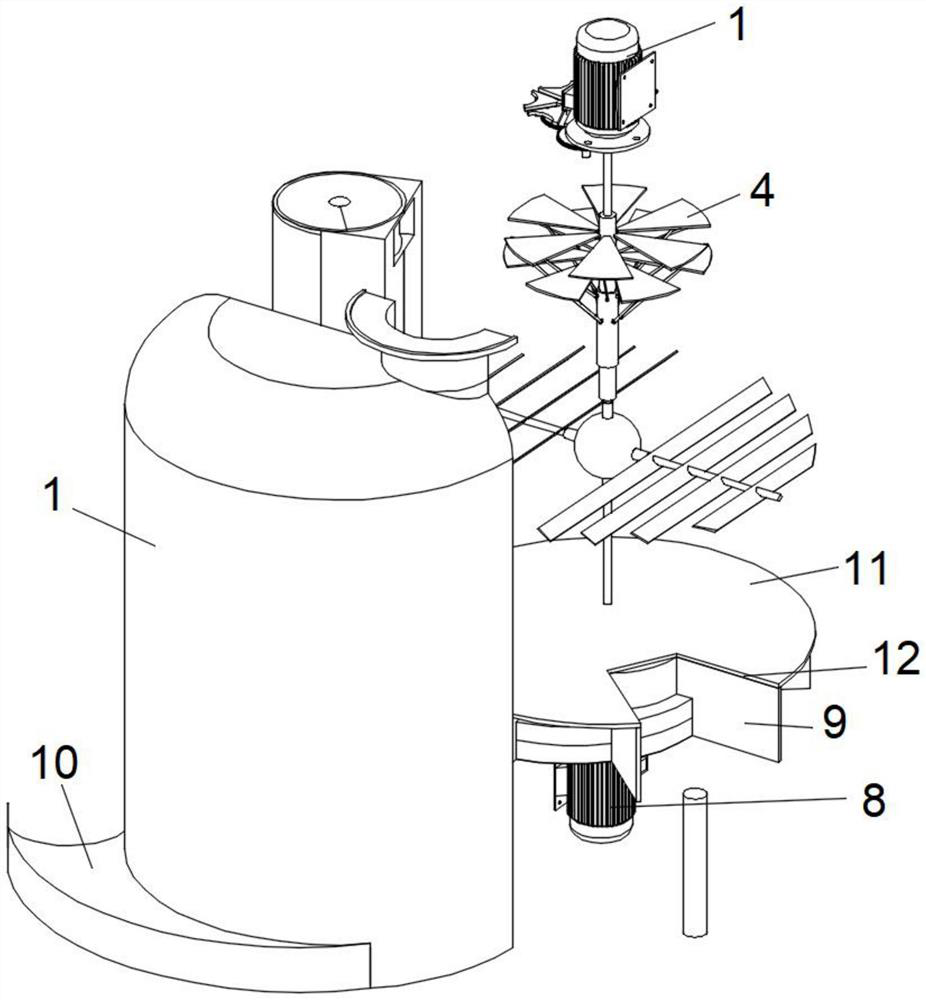

[0039] Example: such as Figure 1-8 As shown, the present invention provides a polypropylene synthesis reaction kettle, comprising a tank body 1, a motor A3 is fixed in the middle of the top surface of the tank body 1 through a mounting plate A2, and the output end of the motor A3 runs through the tank body 1 and is fixed with a stirring assembly 4. The top surface of the tank body 1 is welded with a feed pipe 5, and one side of the feed pipe 5 is provided with an observation tube 6. The bottom surface of the tank body 1 is fixed with a motor B8 through the mounting plate B7, and the output end of the motor B8 runs through the tank. The body 1 is fixed with a transmission component 9, the outer bottom of the tank body 1 is welded to the guide cover 10, the inner lower part of the tank body 1 is welded with a baffle plate 11, and the inside of the baffle plate 11 is provided with a gap 12;

[0040] Stirring assembly 4 comprises the rotary shaft A41 that is coaxially connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com