Satellite type computer conduction band washing-free direct printing system

A washing-free and belt-guiding technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of limited application range, lack of affinity, and paper resource consumption, so as to avoid paper consumption, improve accuracy, and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

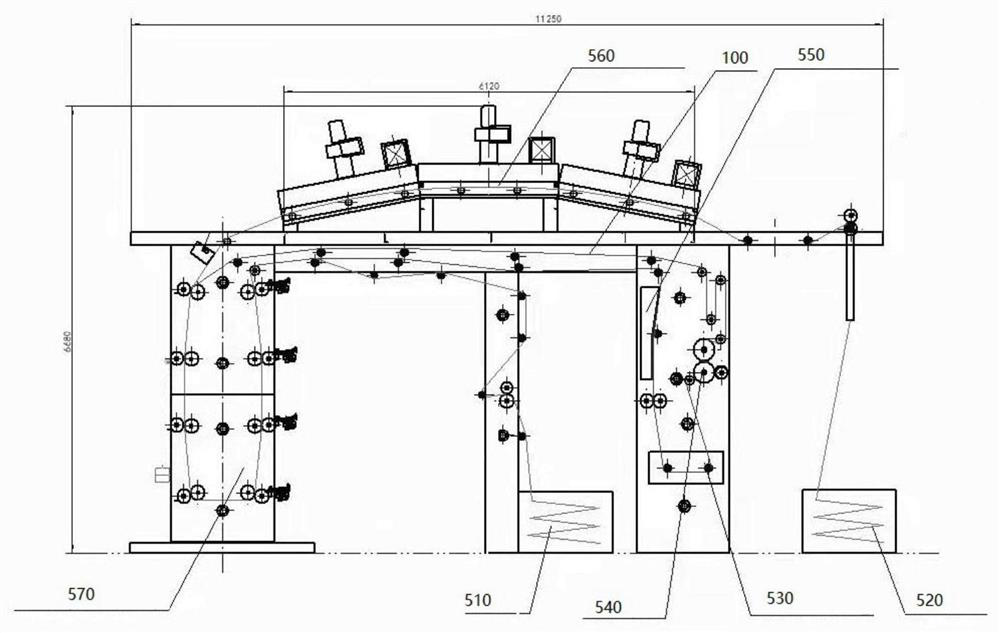

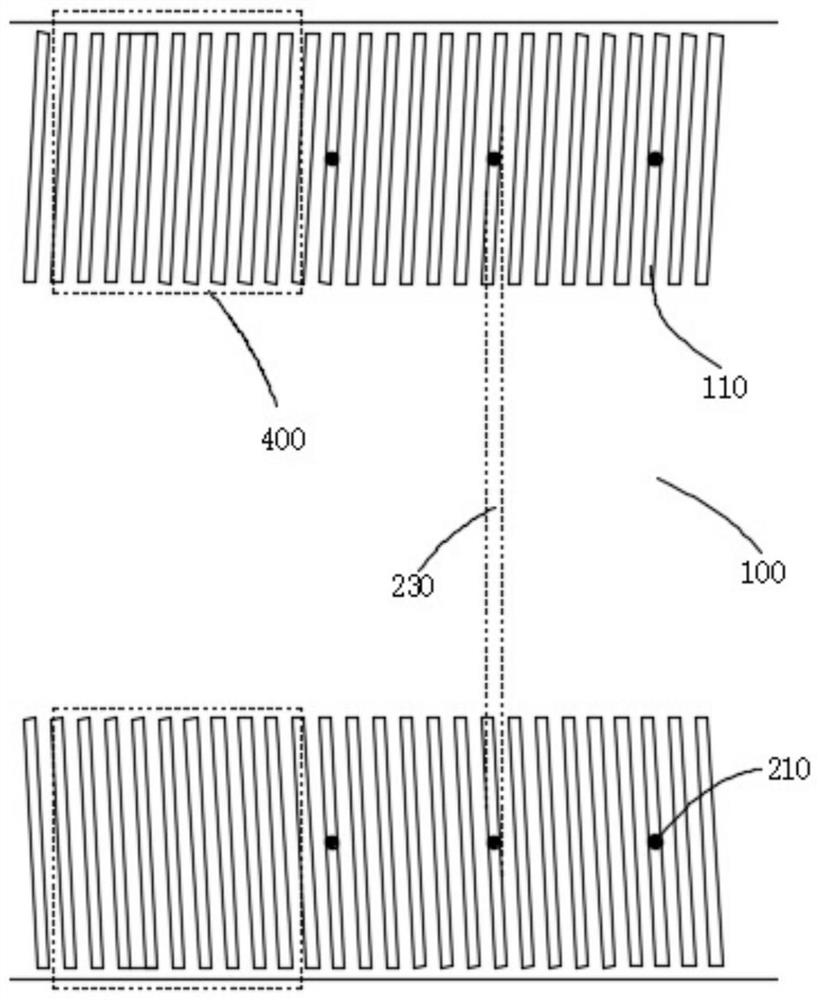

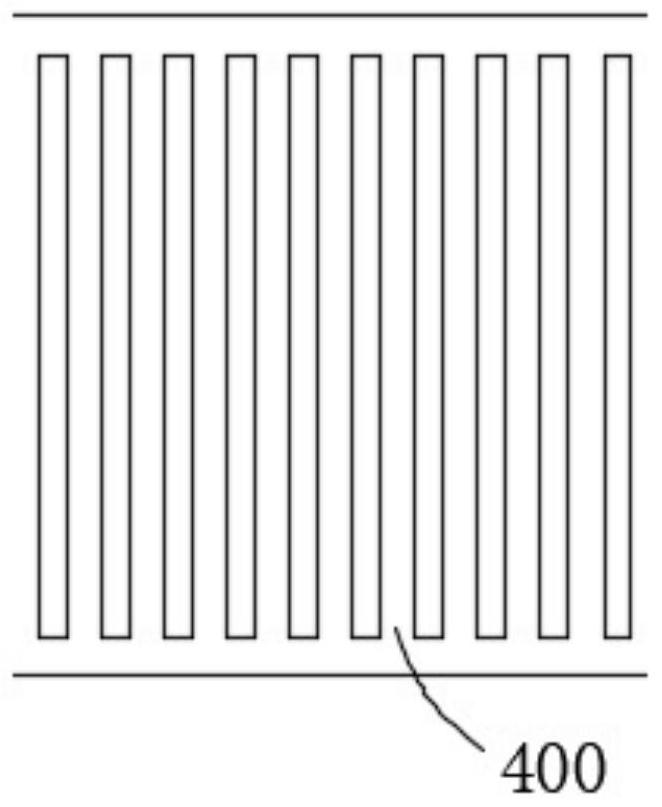

[0026] In this example, see Figure 1-Figure 4 , the satellite-type computer-guided direct printing system includes an unwinding device 510, a rewinding device 520, a guide belt 100, a guide belt washing device 530, a guide belt drying device 550, an oven 560, and a printing assembly 570. The package 510 sends the fabric into the printing assembly 570 through the traction roller 540, and the guide belt 100 is guided to the printing assembly by the traction roller 540 after passing through the guide belt washing device 530 and the guide belt drying device 550 570 is co-linearly transported after bonding with the fabric, and the guide belt 100 is peeled off by the traction roller 540 after the fabric is printed and returned to the guide belt washing device 530 to form a closed loop, and the fabric is printed by the traction roller 540 Guide to the oven 560, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com