Process for treating wastewater generated in production of PBAT and PBS polyester biodegradable resins

A biodegradable resin and waste water production technology, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the difficulty and inability of polyester biodegradable resin production waste water treatment Ensure that the wastewater discharges up to the standard, increase the salt content of the wastewater, etc., to achieve the effects of reducing biological toxicity and pollution, good effluent quality, and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

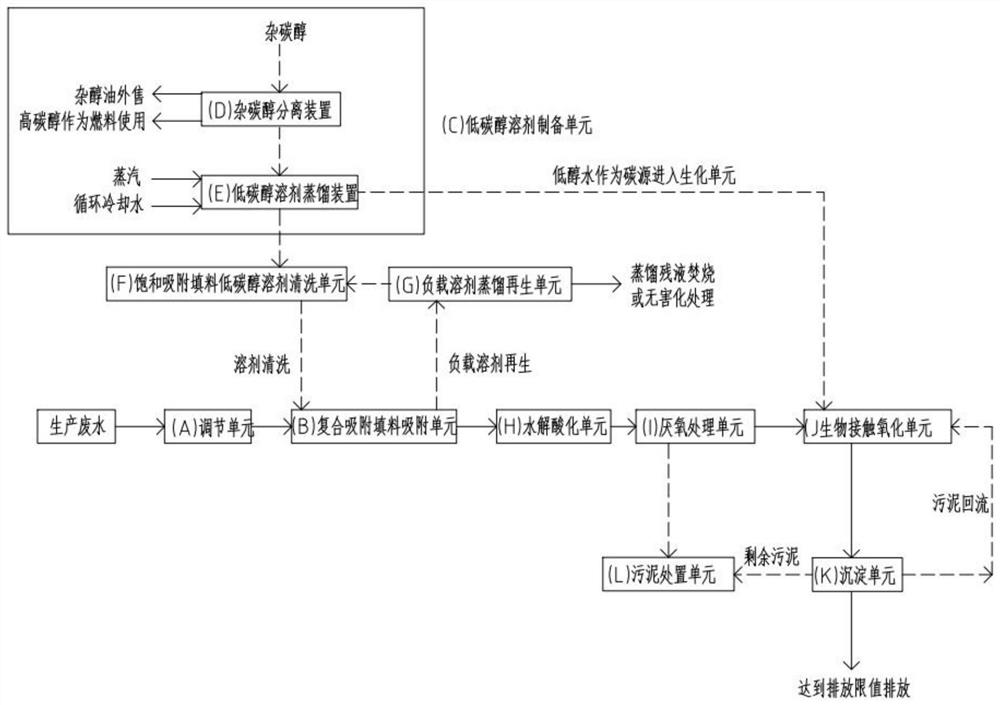

[0033] see figure 1 , a PBAT, PBS polyester biodegradable resin production wastewater treatment process, including adjustment unit, composite adsorption filler adsorption unit, low-carbon alcohol solvent preparation unit, saturated resin low-carbon alcohol solvent cleaning regeneration unit, load solvent distillation regeneration unit , hydrolytic acidification unit, anaerobic treatment unit, biological contact oxidation treatment unit, sedimentation unit and sludge disposal unit, the treatment process steps are as follows:

[0034] A. Adjusting the water volume: through the regulating tank of the regulating unit, the water quantity and water quality in the process of wastewater discharge can be adjusted to prevent the occurrence of uneven and unstable water quality in the process of production wastewater discharge, avoiding the abnormality of the wastewater treatment process and the reduction of the treatment effect ;

[0035] B. Adsorption: The composite adsorption filler f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com