Land thin film liquid hydrogen storage tank with high-vacuum insulation box

An insulating box and high-vacuum technology, applied in the direction of fixed-capacity gas storage tanks, gas/liquid distribution and storage, container discharge methods, etc., can solve the problems of transportation and storage limitations, hydrogen volatilization, etc., and reduce on-site construction The effect of reducing the amount, reducing the evaporation rate and improving the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention.

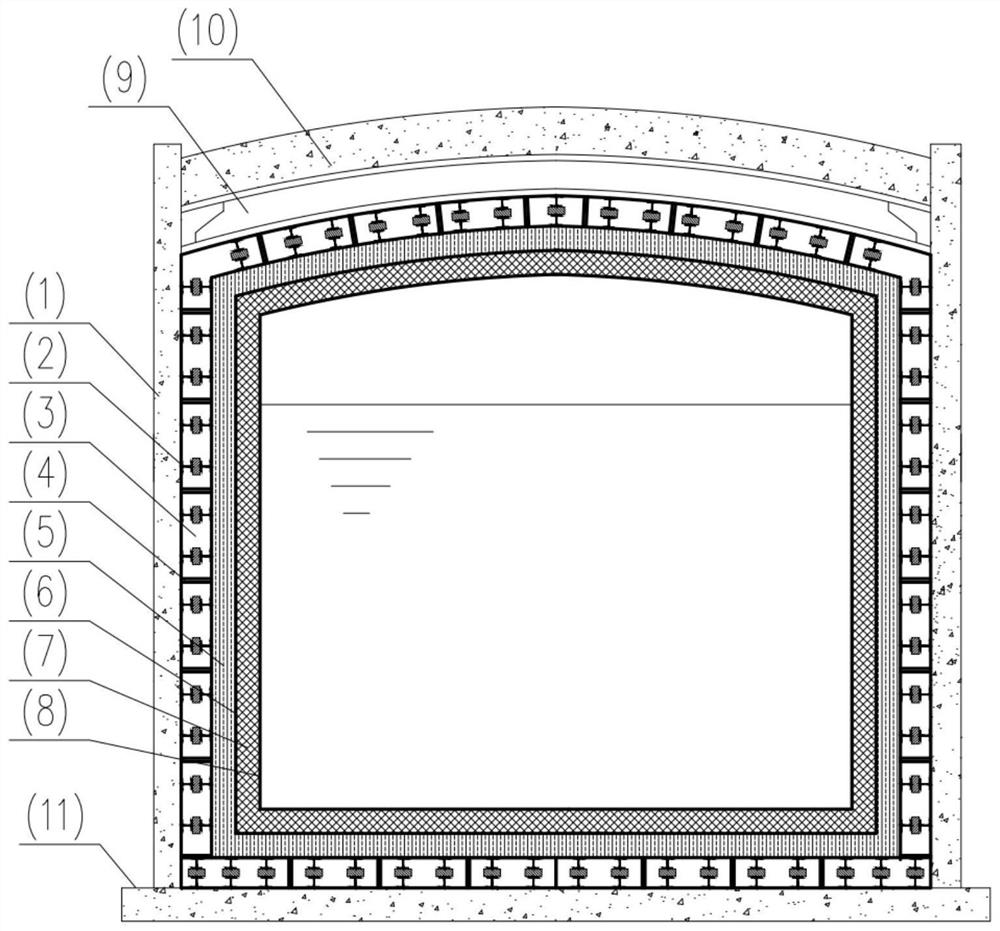

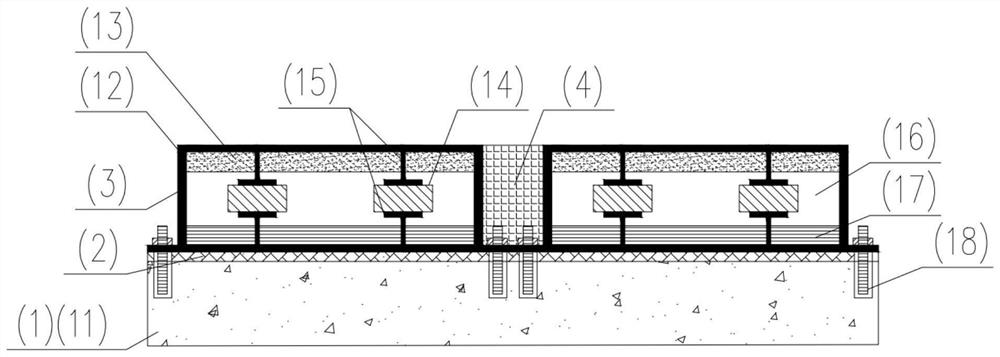

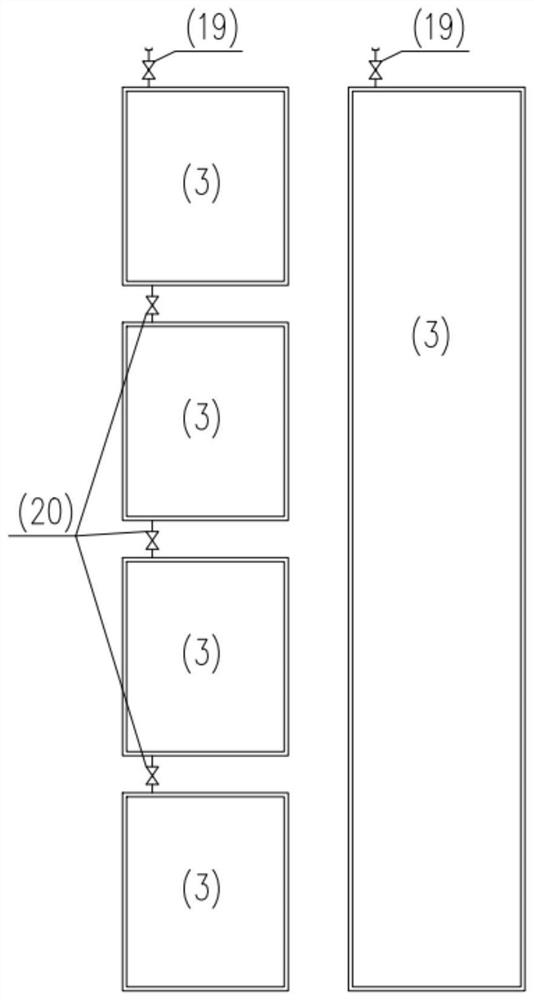

[0031] see Figure 1-4 , the invention is based on the design of double-layer metal film and high-vacuum insulation box, and realizes a set of independent film shielding layer liquid storage system, and adopts the heat insulation method of high-vacuum insulation box, which improves the insulation of traditional film-type storage tanks Cooling performance, further reducing the evaporation rate, increasing the storage time of liquid cargo hydrogen in the storage tank; using a complete set of high vacuum insulation box system, prefabricated high vacuum insulation box modules, reducing the amount of on-site construction, effectively reducing external heat transfer, thereby reducing The evaporation rate of liquid hydrogen; the use of prefabricated film shielding laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com