Oil-cooled flat wire motor with cooling three-phase lead

A three-phase, oil-cooled technology, applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of low filling rate of round wire coils, poor heat dissipation effect, long winding ends, etc., to improve motor efficiency and reduce Effect of copper loss and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

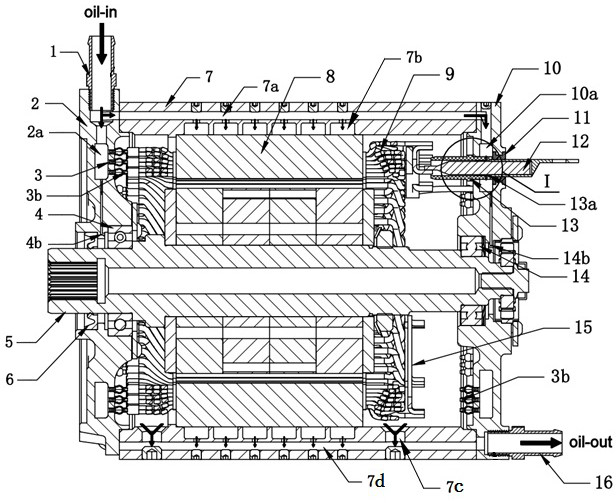

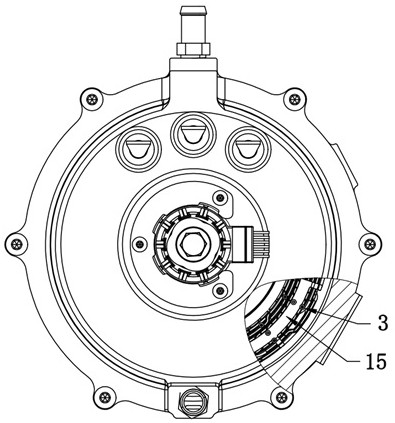

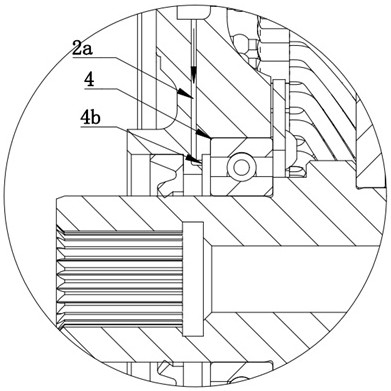

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a kind of oil-cooled flat-wire motor with cooling three-phase leads, including casing 7, and front end cover 2 and rear end cover 10 installed at both ends of casing 7, front and rear end covers 2 and 10 is sealed and connected with the casing 7 to form a cooling oil chamber, the front bearing 4 and the rear bearing 14 are installed on the front end cover 2 and the rear end cover 10 respectively, the motor rotor 5 penetrates in the front and rear bearings, and the motor rotor 5 and the An oil seal 6 is arranged between the front end covers 2, the stator core 8 is fixed to the casing 7 through interference and keyway positioning, the flat wire armature 9 is embedded in the stator core 8, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com