Preparation method and system of black rice and highland barley yoghourt

A technology of highland barley and black rice, which is applied in the field of black rice highland barley yogurt preparation, can solve the problems of uneven fermentation of yogurt, and achieve the effects of easy industrial scale production, uniform fermentation degree, and low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

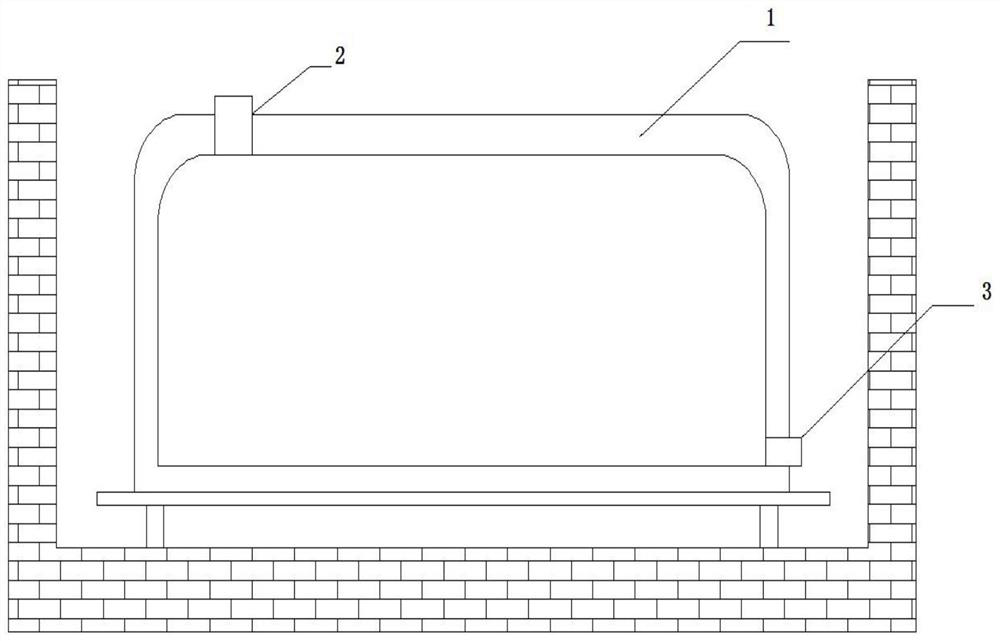

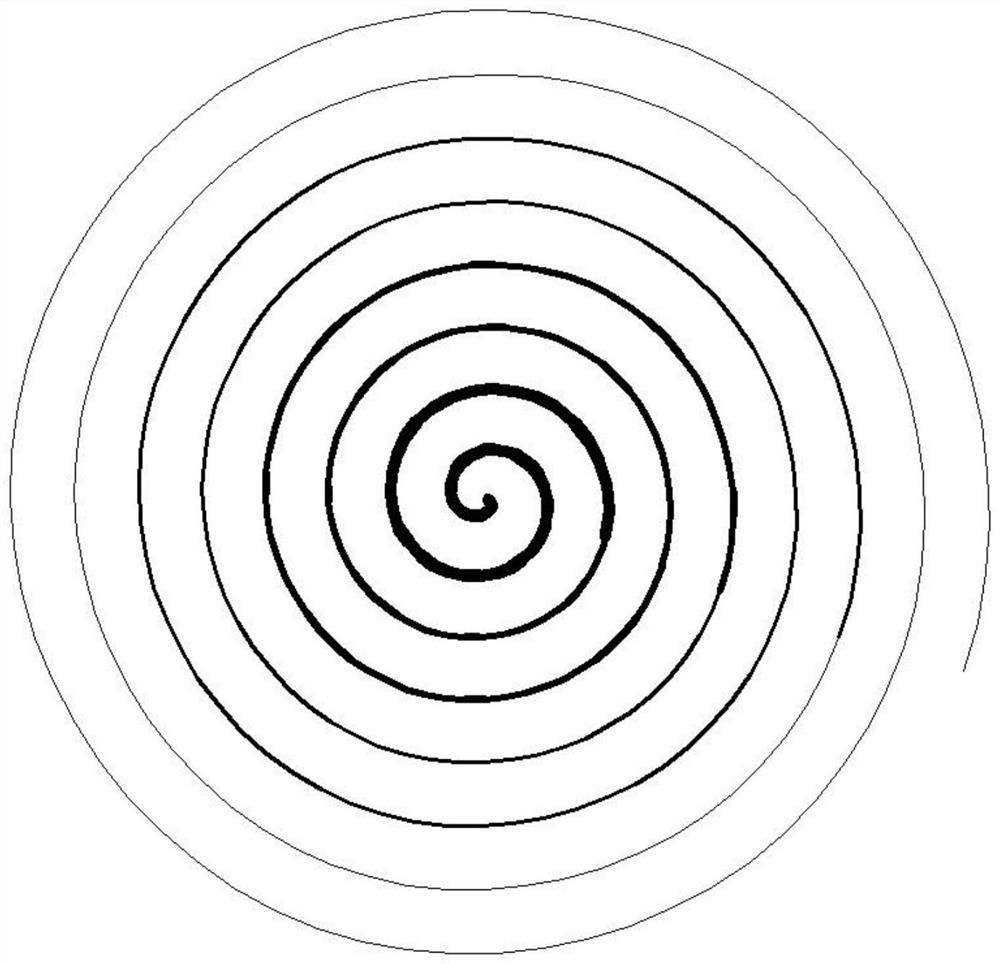

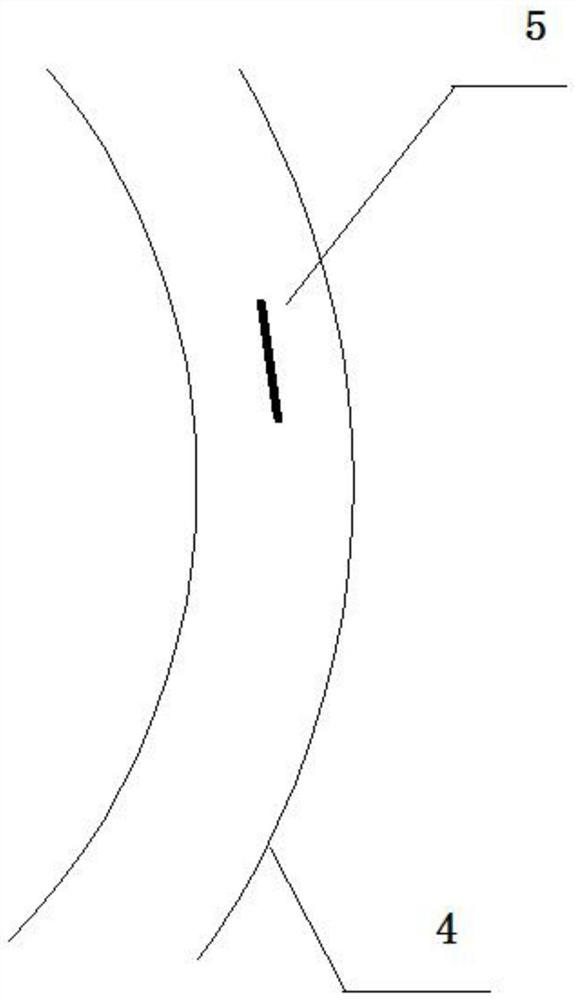

[0042] The present invention, especially the preparation system, will be further described in detail below in conjunction with the accompanying drawings. Embodiment: a black rice highland barley yogurt preparation system, including a heating device, a stirring device, a sterilizing device, a homogenizer and a fermentation chamber; the heating device is used to heat fresh milk to about 80°C; the stirring device It is used to stir the mixture composed of fresh milk, sugar and stabilizer to make it uniform; the output port of the heating device is connected to the input port of the stirring device, and the connection between the output port of the heating device and the input port of the stirring device The pipeline is provided with a valve; the sterilizing device is used to sterilize the mixture composed of fresh milk, sugar and stabilizer at a temperature of 90°C;

[0043] The homogenizer is used for homogenizing the mixture composed of fresh milk, sugar and stabilizer; the fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com