Baimuxiangye oolong tea and its production process

A technology of white wood fragrant leaves and oolong tea, which is applied in the field of tea products, can solve the problems of difficult operation by workers, high requirements for equipment operation, and high requirements for equipment parameters, and achieve the advantages of easy molding, uniform taste and shape, and clear pattern and texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

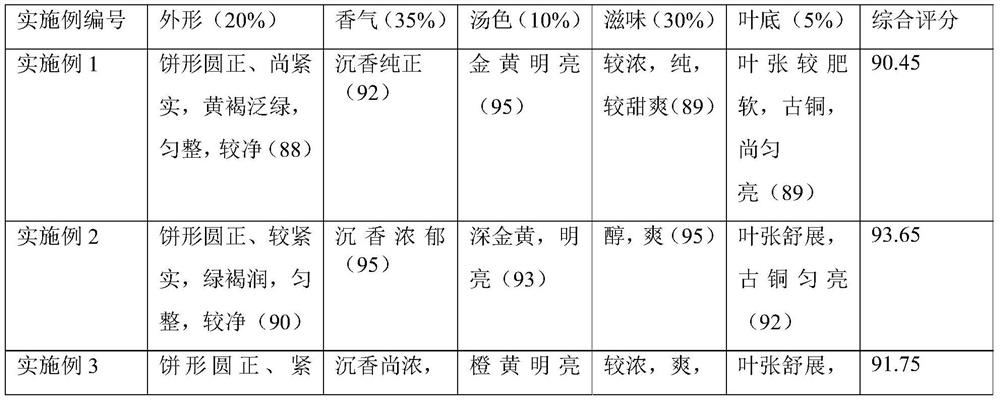

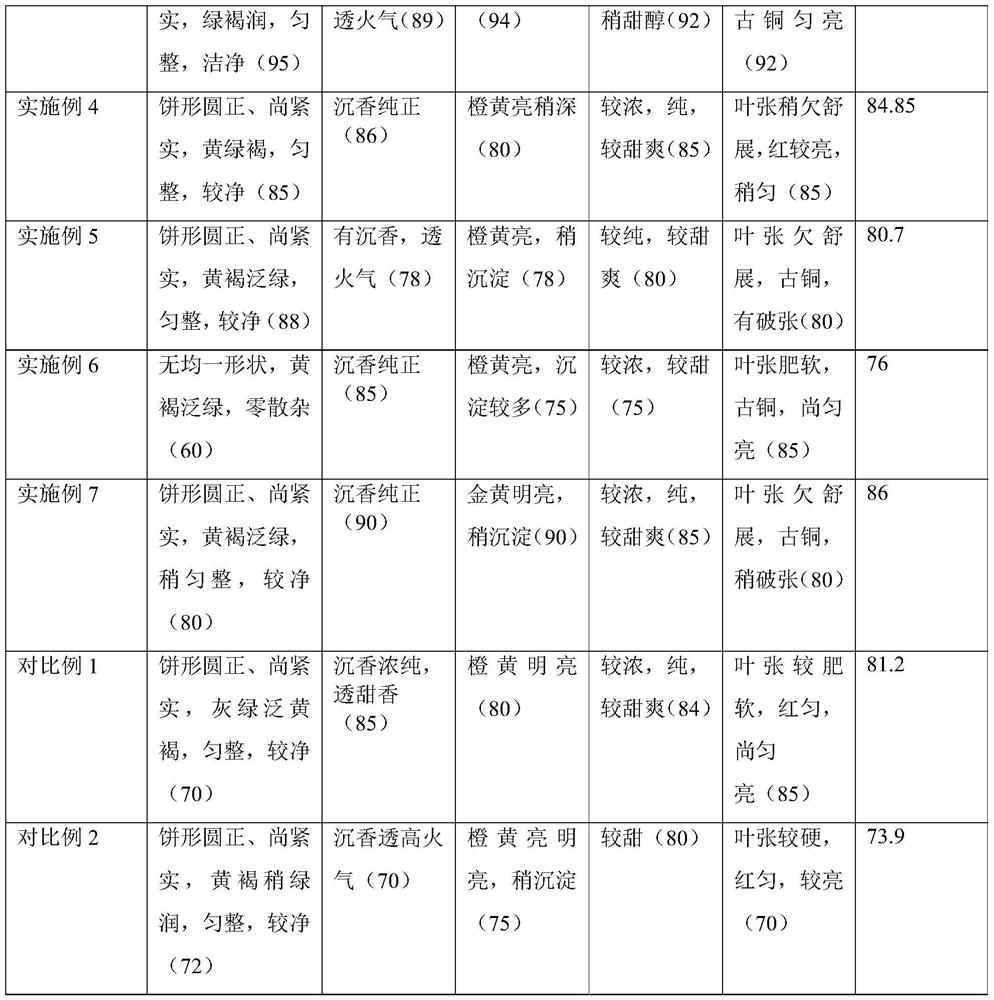

Examples

preparation example Construction

[0035] In a first aspect, the present invention provides a method for preparing Baimuxiangye oolong tea, the method comprising: sequentially withering, cutting, rolling, fermenting, first drying, first drying and roasting the fresh leaves of Baimuxiang to enhance the aroma ;

[0036] Wherein, the conditions of the withering include: the temperature is 25-35°C, the relative humidity is 65-75%, and the time is 30-36 hours; the relative humidity of the fermentation is ≥95%, the temperature is 25-30°C, and the time is 8-15h.

[0037] As mentioned above, the present invention only includes three steps of withering, cutting and rolling the fresh leaves of Baimuxiang before fermentation. Among them, drying green and shaking green greatly simplifies the preparation process. At the same time, the conditions of withering are controlled at a temperature of 25-35°C, a relative humidity of 65-75%, and a time of 30-36 hours, and the fermentation conditions are controlled at a humidity of ...

Embodiment approach

[0064] The inventor of the present invention found in the research on the existing Baimuxiangye oolong tea that the round grain type is a common product form, and this shape is difficult to improve the product attributes. More importantly, in the effective DBS44 / 011-2018 "Guangdong Provincial Food Safety Local Standard Baimuxiangye", the daily intake per person is required to be ≤3g. When drinking daily, it is difficult to calculate the weight of the round grain type. Based on this, according to a preferred embodiment of the present invention, the method further includes steaming, shaping into a cake, and second drying the hair tea in sequence. The weight of the cake-type white wood fragrant leaf oolong tea prepared by the invention is relatively determined, and it can be more convenient for consumers to drink daily without worrying about the problem of excess. In addition, the three-stage process of steaming, forming cake and second drying of the present invention is not onl...

Embodiment 1

[0078] This example is used to illustrate the white wood fragrant leaf oolong tea provided by the present invention and its preparation method

[0079] (1) Picking and sorting of fresh leaves

[0080] Pick the mature leaves of the white wood incense tree, remove the residual leaves, diseased leaves, and non-agarwood leaf inclusions, and use clean, non-polluting, good permeability containers to ship fresh leaves. Lay out the fresh leaves after finishing, the thickness is 1cm, and the stirring action should be light, so as not to damage the fresh leaves and promote oxidation.

[0081] (2) Wither

[0082] In a withering tank with a temperature of 25°C and a relative humidity of 70%, the thickness of the withered leaves is 1cm, and they are stacked every 12 hours. A moderate mark, which lasted 36 hours, and the water content of fresh leaves after withering was about 60%.

[0083] (3) Cut strips

[0084] The withered leaves are cut into strips of about 1.5 cm with a tooth cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com