Airtight aerobic production process of bio-organic fertilizer by municipal sludge or kitchen biogas residues

A bio-organic fertilizer and municipal sludge technology, which is applied in the field of closed aerobic production of bio-organic fertilizer from urban sludge or kitchen biogas residue, can solve the problems of corruption, increased operating costs, and polluted the environment, and achieves the degree of material fermentation Uniformity, high degree of automation, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

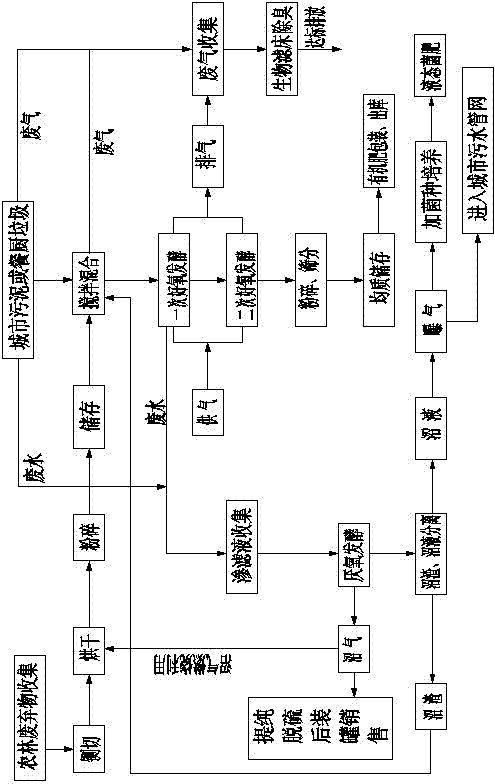

[0034] like figure 1 Shown, municipal sludge of the present invention or cooking biogas slag airtight aerobic bio-organic fertilizer process comprises the following steps:

[0035] (1) Collect sludge or kitchen residue, collect agricultural and forestry waste, and mix the two to reduce the moisture content of the mixture to 55%-65%, preferably 60%;

[0036](2) Transport the mixture to a closed horizontal double-layer cylinder aerobic fermentation tank for an aerobic fermentation, and at the same time supply air to the closed horizontal double-layer cylinder aerobic fermentation tank. The temperature of the primary aerobic fermentation is 65°-75°, preferably 70°;

[0037] (3), then transport the mixture to a closed horizontal aerobic fermentation tank for secondary aerobic fermentation, and at the same time supply air to the closed horizontal aerobic fermentation tank, the temperature of the secondary aerobic fermentation is 50°-60°, Preferably 55 °, after the secondary aerob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com