Method and device for gas burner

A burner and fuel technology, which is applied to burner control devices, gas turbine devices, burners, etc., can solve problems such as no disclosure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

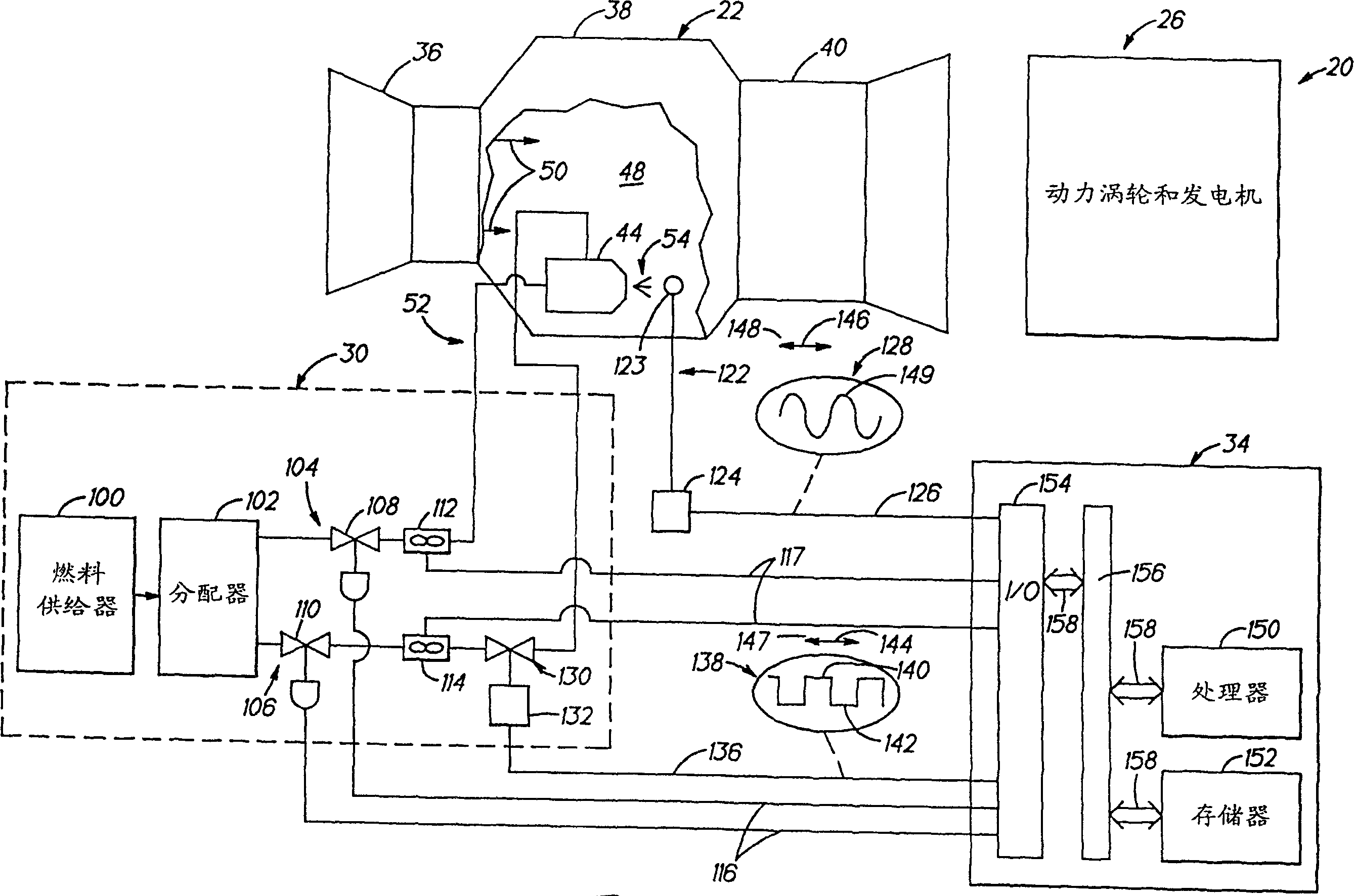

[0035] The invention disclosed herein is for figure 1 The preferred embodiment of the gas turbine power plant is shown. Gas turbine power plant 20 includes a gas turbine 22 , a power turbine and generator 26 , a fuel system 30 and a gas turbine controller 34 . The gas turbine receives fuel from fuel system 30 under the control of gas turbine controller 34 and combusts the fuel to drive power turbine and generator 26 .

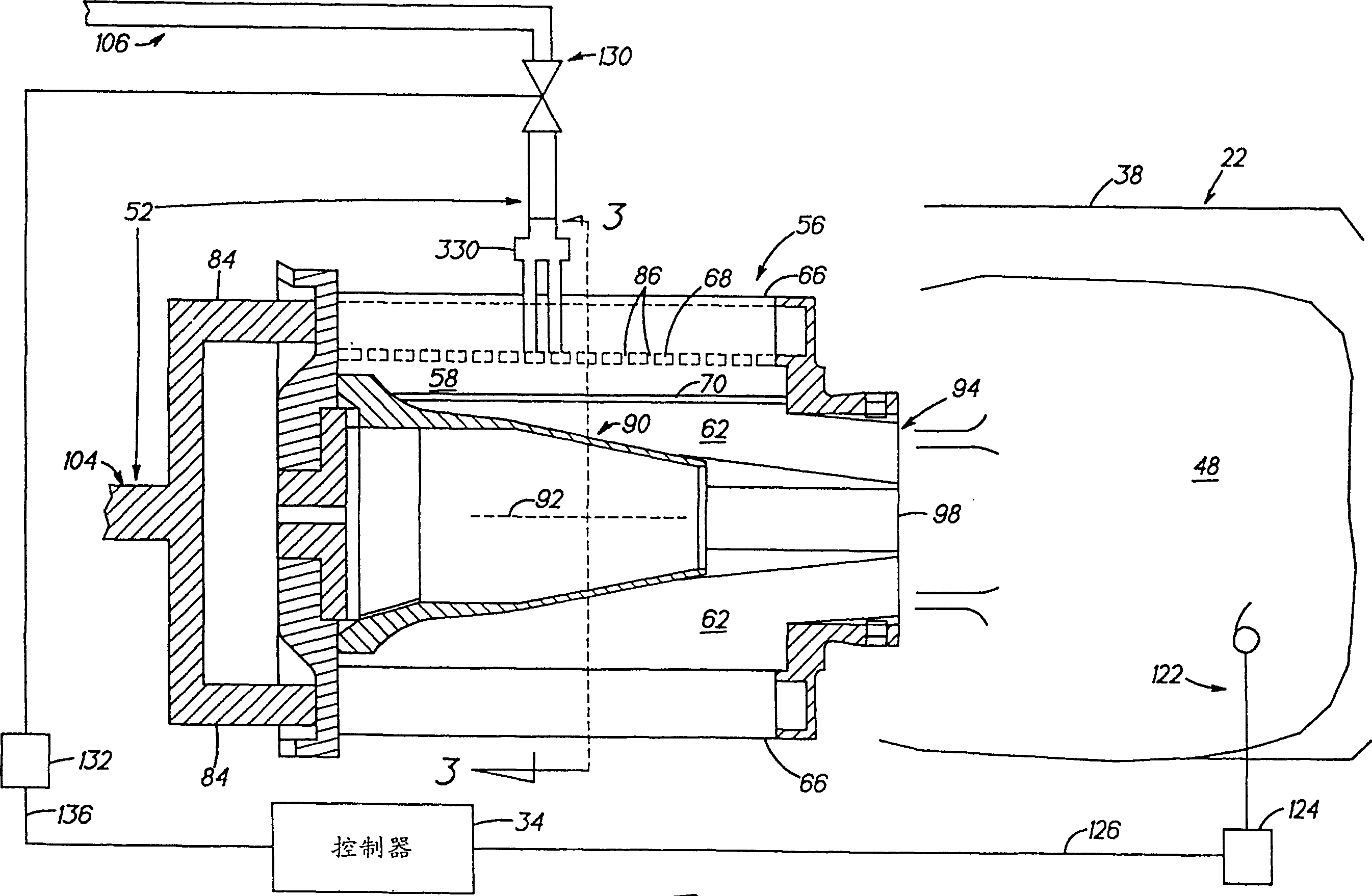

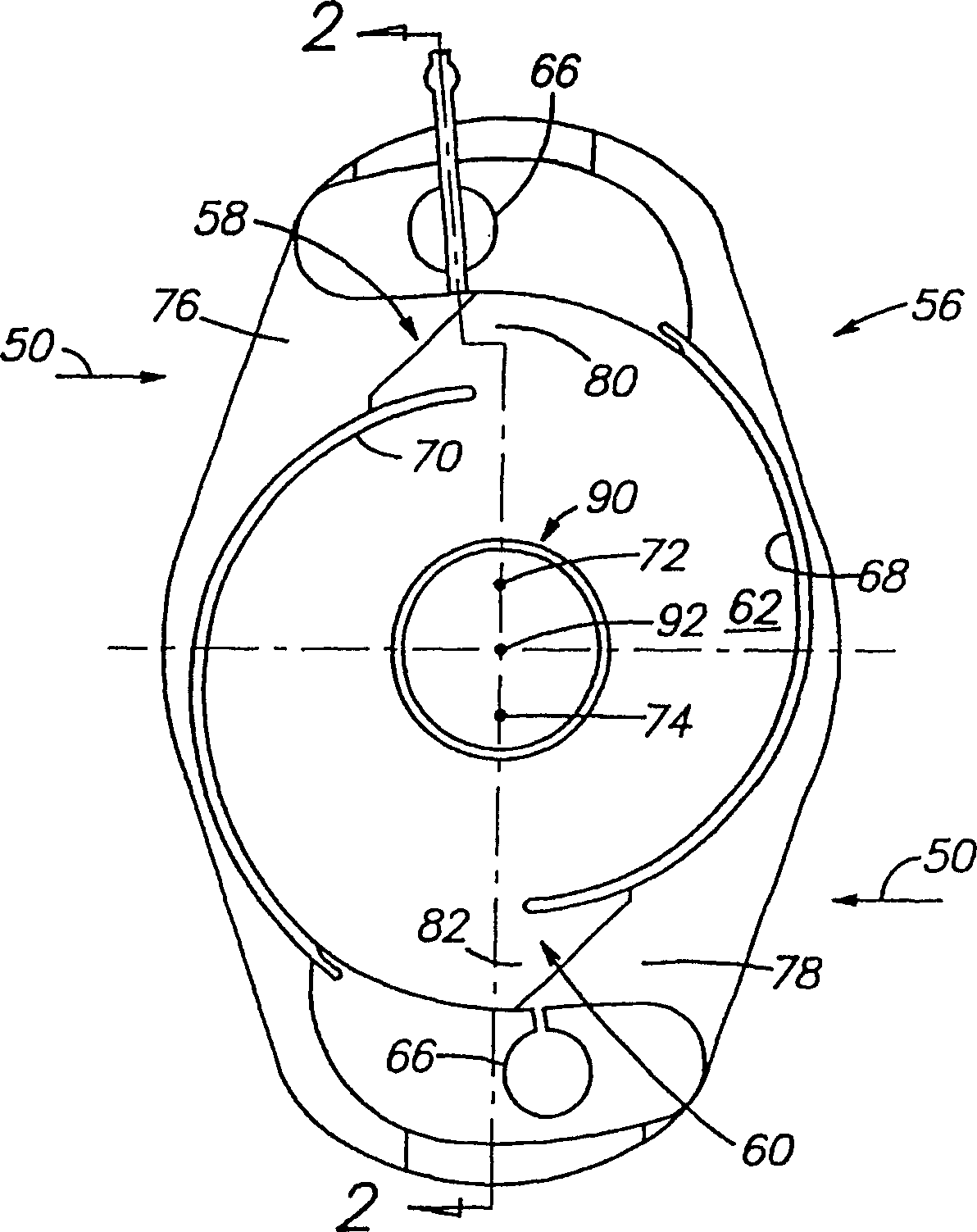

[0036] The gas turbine 22 includes a compressor 36 , a combustion section 38 (partially cut away for clarity) and a turbine 40 . Combustion section 38 typically includes a plurality, for example 16, of premixers (indicated by premixer 44 ) and a burner 48 . Premixers 44 may be spaced circumferentially about the upstream end of combustion section 38 . The burner 48 is preferably annular and is located downstream of the premixer 44 . The premixer receives and mixes compressed air 50 from compressor 36 and fuel provided from fuel system 30 by a plurality of fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com